Alcohol-water separation recycling method of fischer-tropsch synthesis reaction water

A Fischer-Tropsch synthesis and alcohol-water separation technology, applied in the field of environmental protection and resource utilization, can solve the problems of insufficient use of reaction water and high energy consumption, achieve good environmental protection and economy, reduce operating energy consumption, and save resources and energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

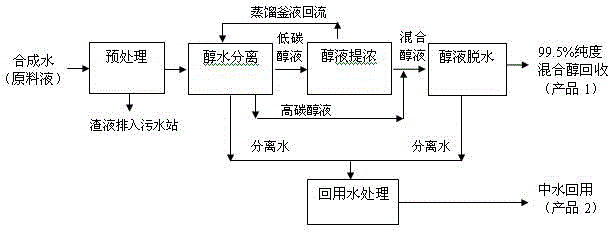

Image

Examples

Embodiment 1

[0027] Synthetic water source: F-T synthetic reaction water using cobalt-based catalysts. pH value is 3, it contains C1-C8 alcohol, the total mass content of alcohol is 5.5%, trace alkanes and alkenes, the rest is water, and the oil content is 350mg / L.

[0028] (1) Pretreatment: The Fischer-Tropsch synthesis reaction water is neutralized by adding alkali to a pH value of 9. After coagulation reaction, it enters the air flotation system to remove oil and impurities, and then is further treated by sand filter and precision filter to obtain oil-containing Raw material water containing mixed alcohol with an amount of 4mg / L;

[0029] (2) Separation of alcohol and water: the pretreated raw water enters the alcohol-permeable membrane device of the organic composite membrane for pervaporation treatment, separates the alcohol and water, and obtains separated water and 33% (wt) low-concentration mixed alcohol liquid; reuse The liquid-liquid separation device separates the separated low...

Embodiment 2

[0034] Synthetic water source: F-T synthetic reaction water using cobalt-based catalysts. pH value is 4, it contains C1-C8 alcohol, the total mass content of alcohol is 4.2%, trace alkanes and alkenes, the rest is water, and the oil content is 300mg / L.

[0035] (1) Pretreatment: The Fischer-Tropsch synthesis reaction water is neutralized by adding alkali to a pH value of 6. After coagulation reaction, it enters the air flotation system to remove oil and impurities, and then is further treated by sand filter and precision filter to obtain oil-containing The amount is the raw material water containing mixed alcohol of 4.5mg / L;

[0036] (2) Separation of alcohol and water: the pretreated raw water enters the alcohol-permeable membrane device of the organic composite membrane for pervaporation treatment, separates the alcohol and water, and obtains separated water and 28% (wt) low-concentration mixed alcohol liquid; reuse The liquid-liquid separation device separates the separate...

Embodiment 3

[0041]The working steps of this example are basically the same as those of Example 2, the difference is that in (1) pretreatment, the Fischer-Tropsch synthesis reaction water is neutralized to a pH value of 7.5 by adding alkali, and in step (5), return to During water treatment, reusable reclaimed water with a pH value of 7.3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com