A kind of formula for grinding steel ball emery wheel

A technology for grinding steel balls and grinding wheels, which is applied to abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced durability, reduced grinding wheels, and reduced grinding efficiency, so as to improve durability, reduce cracks, and reduce grinding The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

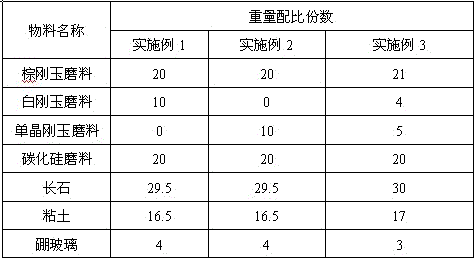

[0007] Formulate the grinding wheel formula as follows:

[0008]

[0009] Accurately weigh various materials according to the formulas of the above-mentioned Example 1, Example 2, and Example 3 respectively, put them into a ball mill after mixing, discharge and sieve after ball milling, and make emery wheels according to conventional methods. After the grinding wheel made according to Example 1 was tested in a steel ball factory in Hefei, the discharging time of each ball was reduced from 10 hours to 7.5-8 hours, and the grinding efficiency was increased by 20-25%. After the grinding wheel manufactured according to Example 2 was tested in a steel ball factory in Changzhou, each grinding wheel was improved from grinding 36 balls to grinding 40-41 balls, and the durability increased by 11.11-13.88%. After the grinding wheel made according to Example 3 was tested in a steel ball factory in Zhejiang, the discharge time of each ball was reduced from 10 hours to 8-8.5 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com