Low-hydrogen electrode for root welding on pipelines

A low hydrogen type, root welding technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of poor welding arc stability, poor welding process performance, poor operating performance, etc., and achieve the arc blowing force. Large, easy to double-sided forming, large penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

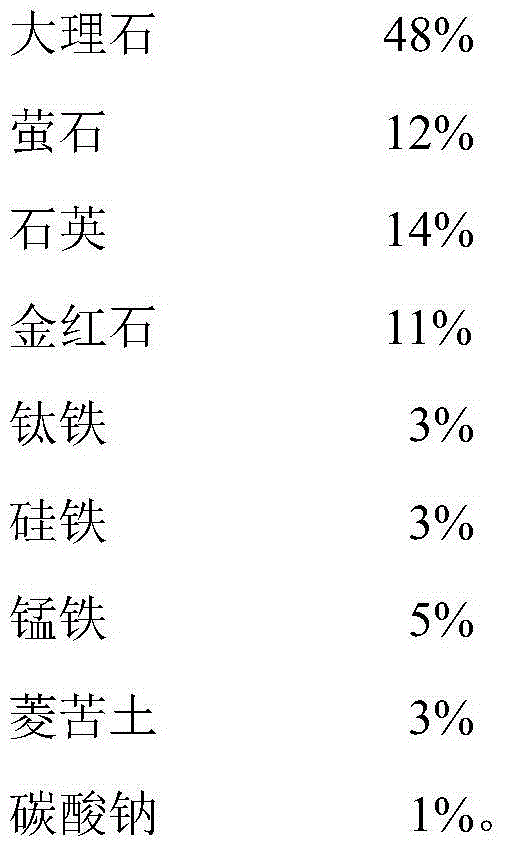

[0021] Take marble powder, fluorite powder, quartz powder, rutile powder, ferro-titanium powder, ferrosilicon powder, ferro-manganese powder, magnesite powder, and sodium carbonate powder, and mix them in the following mass fraction ratio:

[0022]

[0023] Mix the above mixed ingredients evenly as the raw material of the electrode coating, and set aside;

[0024] Take a wire rod with a suitable diameter and a material of H08A, cut it into a suitable length as the welding core of the welding rod, and set it aside;

[0025] The above raw materials are made into finished welding rods according to the known preparation methods of welding rods, that is, low-hydrogen welding rods for root welding of pipelines are obtained.

[0026] Pipeline root welding is performed on this electrode. The electrode has good welding process performance. The welding process realizes single-sided welding and double-sided forming. At the same time, the weld shape is beautiful and the slag removal is...

Embodiment 2

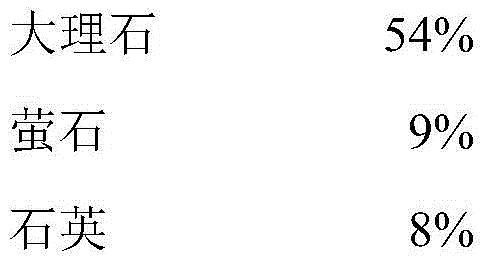

[0028] Take marble powder, fluorite powder, quartz powder, rutile powder, ferro-titanium powder, ferrosilicon powder, ferro-manganese powder, magnesite powder, and sodium carbonate powder, and mix them in the following mass fraction ratio:

[0029]

[0030]

[0031] Mix the above mixed ingredients evenly as the raw material of the electrode coating, and set aside;

[0032] Take a wire rod with a suitable diameter and a material of H08A, cut it into a suitable length as the welding core of the welding rod, and set it aside;

[0033] The above raw materials are made into finished welding rods according to the known preparation methods of welding rods, that is, low-hydrogen welding rods for root welding of pipelines are obtained.

[0034] Pipeline root welding is performed on this electrode. The electrode has good welding process performance. The welding process realizes single-sided welding and double-sided forming. At the same time, the weld shape is beautiful and the sla...

Embodiment 3

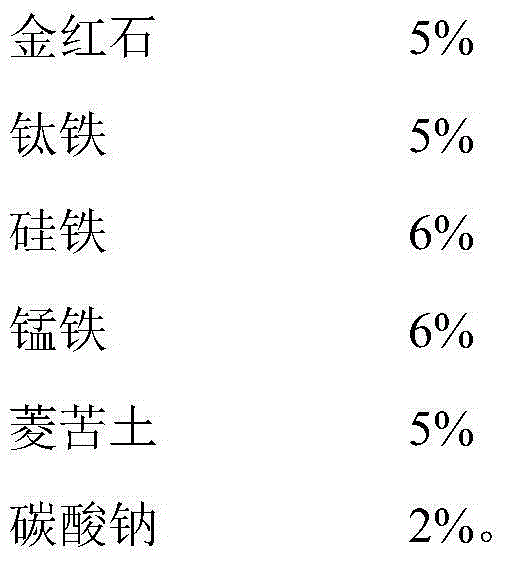

[0036] Take marble powder, fluorite powder, quartz powder, rutile powder, ferro-titanium powder, ferrosilicon powder, ferro-manganese powder, magnesite powder, and sodium carbonate powder, and mix them in the following mass fraction ratio:

[0037]

[0038] Mix the above mixed ingredients evenly as the raw material of the electrode coating, and set aside;

[0039] Take a wire rod with a suitable diameter and a material of H08A, cut it into a suitable length as the welding core of the welding rod, and set it aside;

[0040] The above raw materials are made into finished welding rods according to the known preparation methods of welding rods, that is, low-hydrogen welding rods for root welding of pipelines are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com