Device and method for improving quality of aluminum alloy plasma arc welded joint

A plasma arc and welding joint technology, which is applied in the field of devices for the quality of plasma arc welding joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

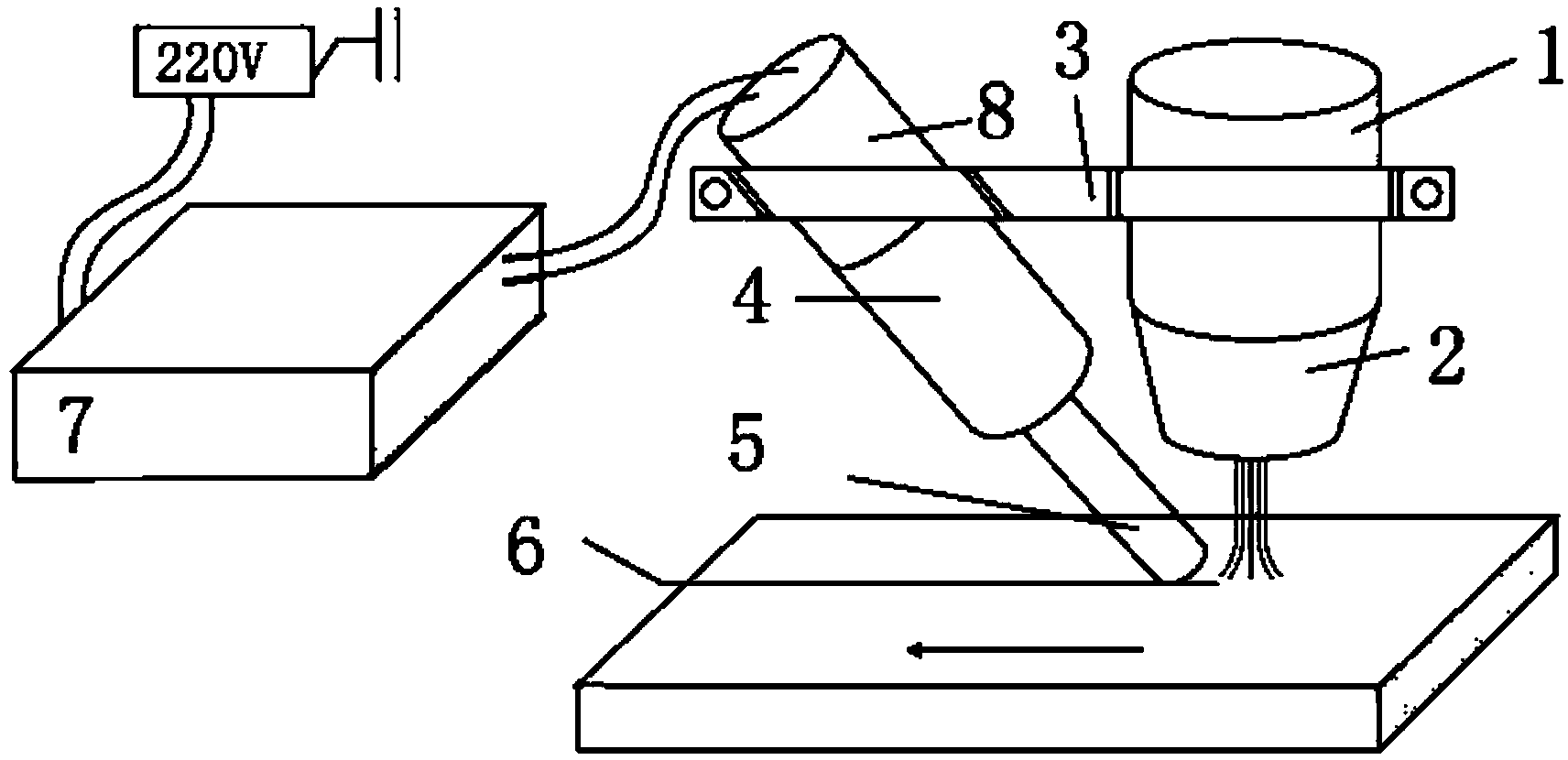

Image

Examples

Embodiment

[0036] (1) Comparative example:

[0037] A 5083 aluminum plate with a thickness of 10 mm is used as the workpiece to be welded, a butt joint test plate with a width of 10 cm and a length of 25 cm. The surface before welding is simply mechanically cleaned with an angle grinder. The plasma welding parameters are: ion gas 1.39L / min forward current 260A, Reverse 290A, welding speed 40mm per minute.

[0038] After welding, ultrasonic non-destructive testing is used to evaluate the porosity level, which is three grades. The porosity is mainly concentrated near the fusion line, and sometimes obvious large porosity can be seen in the cross section.

[0039](2) The welding parameters are the same as those of the comparative example, except that ultrasonic vibration is added, the vibration frequency of the ultrasonic vibration rod is 30KHz, the amplitude is 50um, and the ultrasonic tool head is 5 mm in front of the welding pool. Post-weld ultrasonic non-destructive testing is used to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com