Method for manufacturing single walled carbon nanotube surface nickel copper coating

A technology of single-walled carbon nanotubes and nickel-copper, which is applied in coatings, metal material coating processes, liquid chemical plating, etc., can solve the problems of unsatisfactory macroscopic properties, and achieve avoidance of oxidation side reactions, good wettability, The effect of reducing cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

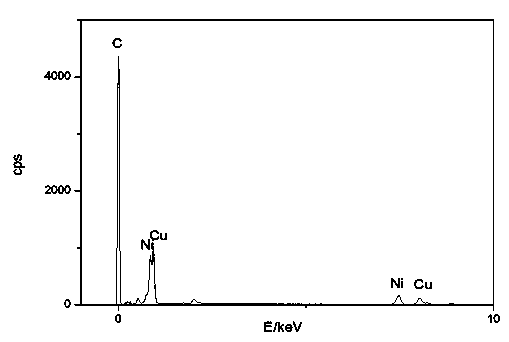

Image

Examples

Embodiment 1

[0034] (1) The dispersion of single-walled carbon nanotubes is to add deionized water, 0.35w / v % SDBS and 0.025w / v% single-walled carbon nanotubes to a beaker, and use a frequency of 35kHz, A probe-type ultrasonic generator with a power of 60W was used for ultrasonic treatment for 30 minutes, during which time the ultrasound was stopped for 5 seconds every 5 seconds.

[0035] Purification pretreatment of single-walled carbon nanotubes: using 6 mol / L HNO 3 Reflux the above-mentioned fully dispersed single-walled carbon nanotubes at 118°C for 5 hours, cool, filter and wash with deionized water until neutral, then reflux with 6 mol / L NaOH at 118°C for 3 hours, cool, and filter and wash with deionized water to pH 7, then reflux with 6 mol / L HCl at 118°C for 3 hours, cool, filter and wash with deionized water until the pH is 7; the concentration of single-walled carbon nanotubes during purification is 0.035w / v%.

[0036] Sensitization and activation treatment of single-walled carbon...

Embodiment 2

[0041] The difference between this example and Example 1 is that the concentration of SDBS during the dispersion treatment in step (1) is 0.5w / v%, the frequency of the probe type ultrasonic generator is 20 kHz, the power is 60W, and the ultrasonic dispersion treatment time is 20min , during which the ultrasound stops for 3 seconds every 2 seconds. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0043] The difference between this example and Example 1 is: during the purification process in step (1), 6 mol / L HNO 3 The temperature of medium reflux is 120°C, and the reflux time is 4.5h; the temperature of reflux in 6 mol / L NaOH is 116°C, and the reflux time is 1.5h; the temperature of reflux in 6mol / L HCl is 116°C, and the reflux time is 1.5h. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com