Hydroximic acid functionalized polymer/inorganic composite chelating adsorption material and preparation method thereof

An inorganic composite, chelating adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc. problem, to achieve the effects of excellent adsorption and desorption performance, strong selective identification, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

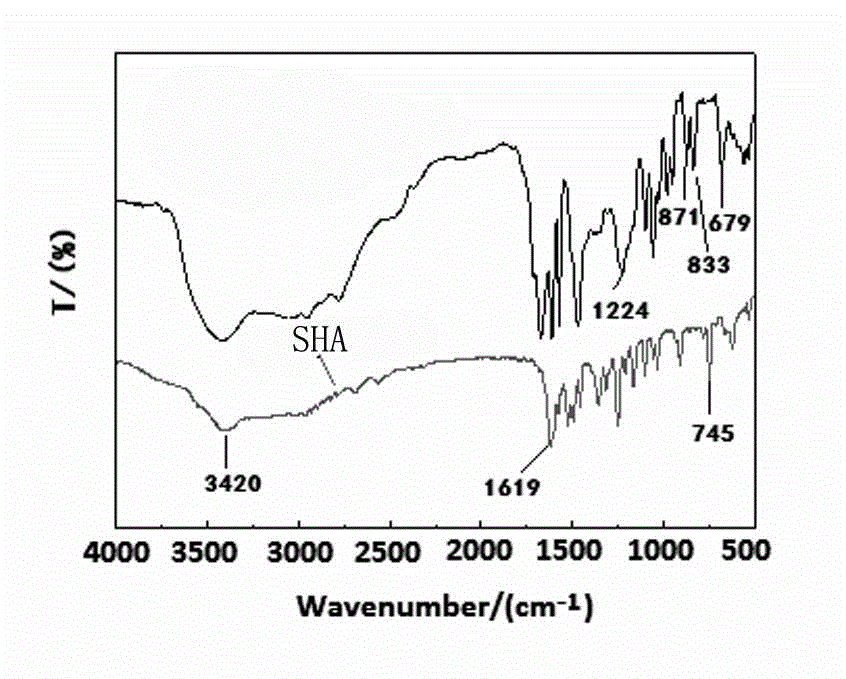

Embodiment 1

[0021] Example 1: In a four-neck flask, add 10g of salicylic hydroxamic acid and 100ml of N,N-dimethylformamide, after the salicylic hydroxamic acid is fully dissolved, add 1,4 - Dichloromethoxybutane 21mL, stir well and add 1.2mL of SnCl 4 , constant temperature reaction for 13h, and then let the reaction solution stand overnight, a white precipitate was precipitated, filtered with suction, washed with ethanol, and dried in vacuo to obtain chloromethyl salicylic hydroxamic acid with a yield of 75%.

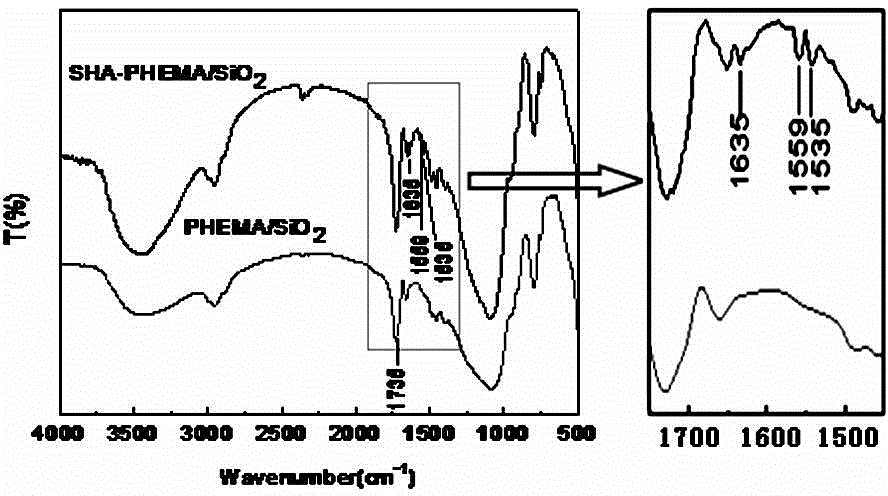

[0022] 0.83g chloromethyl salicylic hydroxamic acid and 0.2 g grafted particles PHEMA / SiO 2 Add it to 20mL dimethyl sulfoxide, raise the temperature to 110°C, and add 1.5g sodium carbonate, N 2 Under protection, react at constant temperature for 10 hours, filter, wash with distilled water and solvent repeatedly, and dry in vacuum to obtain the salicylic hydroxamic acid functionalized polymer / inorganic composite chelating adsorption material SHA-PHEMA / SiO 2 . The bonding ratio ...

Embodiment 2

[0023] Example 2: In a four-necked flask, add 9g of salicylic hydroxamic acid and 80mL of 1,4-dioxane. After the salicylic hydroxamic acid is fully dissolved, add 1,4- Dichloromethoxybutane 18mL, after stirring evenly, add 1.0mL of SnCl 4 , constant temperature reaction for 12h, and then let the reaction solution stand overnight, a white precipitate was precipitated, filtered with suction, washed with ethanol, and dried in vacuo to obtain chloromethyl salicylic hydroxamic acid with a yield of 69%.

[0024] 0.15g chloromethyl salicylic hydroxamic acid and 0.2g grafted particles PHEMA / SiO 2 Add to 12ml of N,N-dimethylformamide, raise the temperature to 90°C, and add 1.3g of sodium carbonate, N 2 Under protection, react at constant temperature for 10 hours, filter, wash with distilled water and solvent repeatedly, and dry in vacuum to obtain the salicylic hydroxamic acid functionalized polymer / inorganic composite chelate adsorption material SHA-PHEMA / SiO 2 . The bonding rate o...

Embodiment 3

[0025] Example 3: In a four-neck flask, add 8g of salicylic hydroxamic acid and 100ml of N,N-dimethylacetamide, after they are fully dissolved, add 1,4-dimethoxylate dropwise through a constant pressure dropping funnel at 5°C Chloromethoxybutane 15mL, after stirring evenly, add 0.8mLTiCl 4 , constant temperature reaction for 10h, and then let the reaction solution stand overnight, a white precipitate precipitated, filtered, washed with ethanol, and dried in vacuo to obtain chloromethyl salicylic hydroxamic acid with a yield of 60%.

[0026] 0.55g chloromethyl salicylic hydroxamic acid and 0.2g grafted particles PHEMA / SiO 2 Add it to 17mL of mixed solvent of dimethyl sulfoxide and N,N-dimethylformamide (V:V=1:1), raise the temperature to 100°C, and add 1g of sodium bicarbonate, N 2 Under protection, react at constant temperature for 9 hours, filter, wash with distilled water and solvent repeatedly, and dry in vacuum to obtain the salicylic hydroxamic acid functionalized polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com