Improved wire cut electrical discharge machine tool

A technology for cutting machine tools and EDM wires, which is applied in electrode manufacturing, electric machining equipment, metal processing machinery parts, etc., and can solve the problems of large voltage loss and low machining efficiency of machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

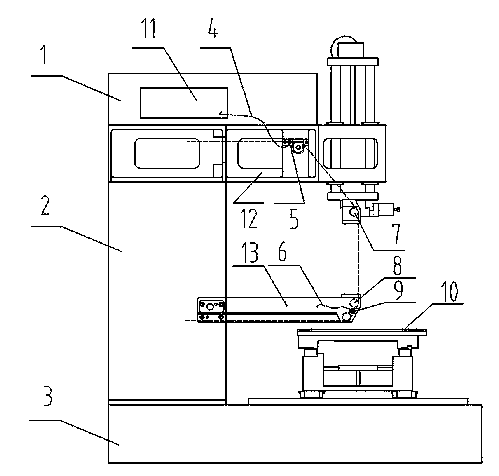

[0018] See attached figure 1 , an improved wire electric discharge machine tool, including a machine tool body and a control cabinet, wherein the machine tool body includes a bed body 3, a wire transport mechanism installed in a cavity of a column 2, a wire rack, a workbench 10, a working fluid system, and a power supply system , machine tool electrical appliances and numerical control system,

[0019] The power system includes a high-frequency pulse power generator 11,

[0020] The wire frame includes a column 2 fixed on the bed and an upper arm 12 and a lower arm 13 connected to the column. The upper arm and the lower arm processing area are respectively equipped with an upper capstan 7, a lower capstan 8 and an upper conductive block 5. , the lower conductive block 9,

[0021] The workbench 10 includes the lower carriage, the upper carriage, the carriage motor, the workbench carriage guide pair, and the transmission assembly. Driven by the carriage motor, the workbench ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com