Screening and drying method for wood chips in production of phosphoric acid method activated carbon

A technology for activated carbon production and sawdust, which is applied in drying, drying machines, chemical instruments and methods, etc., can solve the problems of increased ash content of activated carbon products, consumption of phosphoric acid, and insufficient utilization of resources, so as to reduce the consumption of ash and phosphoric acid, The effect of high thermal efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] A method for screening and drying sawdust in the production of activated carbon mainly includes primary screening, drying, cyclone separation, dust removal and secondary screening.

[0014] 1) Wood chips with a moisture content of 45-60% fall into the first-stage cylindrical sieve through the belt conveyor;

[0015] 2) The screened sawdust with qualified particle size enters the air drying system through the screw conveying auger;

[0016] 3) Oxygen-limited combustion of woody fuel used in hot blast stoves can produce 15-20% carbonized material. The combustion of combustible gas generated by carbonization is used to provide heat source. The drying temperature is controlled at about 320°C, and carbonized material is obtained for the production of physical activated carbon. The hot air is brought into the drying system by the induced draft fan;

[0017] 4) After drying, the sawdust with a moisture content of 15-20% enters the secondary cylindrical sieve through the cyclo...

example 2

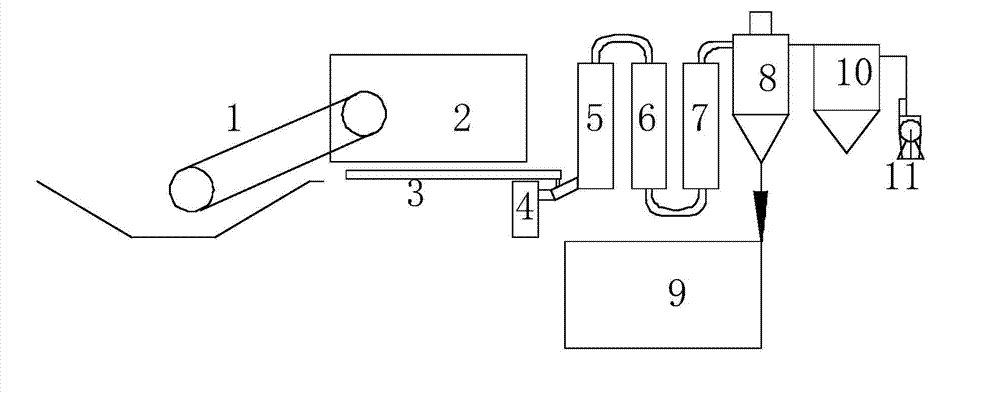

[0019] see figure 1 .

[0020] The wood chips with a moisture content of 45-60% are sent to the first-stage cylindrical sieve 2 through the belt conveyor 1, and the wood chips with a qualified particle size enter the air-flow drying system through the screw conveyor auger 3. The heat source of the entire drying system comes from the hot blast stove 4, and the hot air is controlled. The temperature is 320°C, the hot air passes through the induced draft fan 11 behind the bag filter 10 and enters the drying pipe, the hot air entrains the sawdust, passes through the dryers 5, 6, and 7 in sequence, and then enters the cyclone separator 8, and the sawdust that comes down from the cyclone separator 8 is re- After being selected by the secondary cylindrical sieve 9, wood chips with a moisture content of 15-20% are obtained. The wood chips are used as raw materials for the batching system and mixed with phosphoric acid solution of a certain concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com