Steel pipe tubular joint reinforced by carbon fiber composite reinforcing materials

A technology of intersecting joints and composite reinforcement, applied in building maintenance, construction, building construction, etc., can solve the problem of unsightly appearance of casing, backing plate and ring plate, deterioration of structure and performance of welding parts, and affecting building use space and other issues, to achieve good conversion prospects, short cycle, and reduce the use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

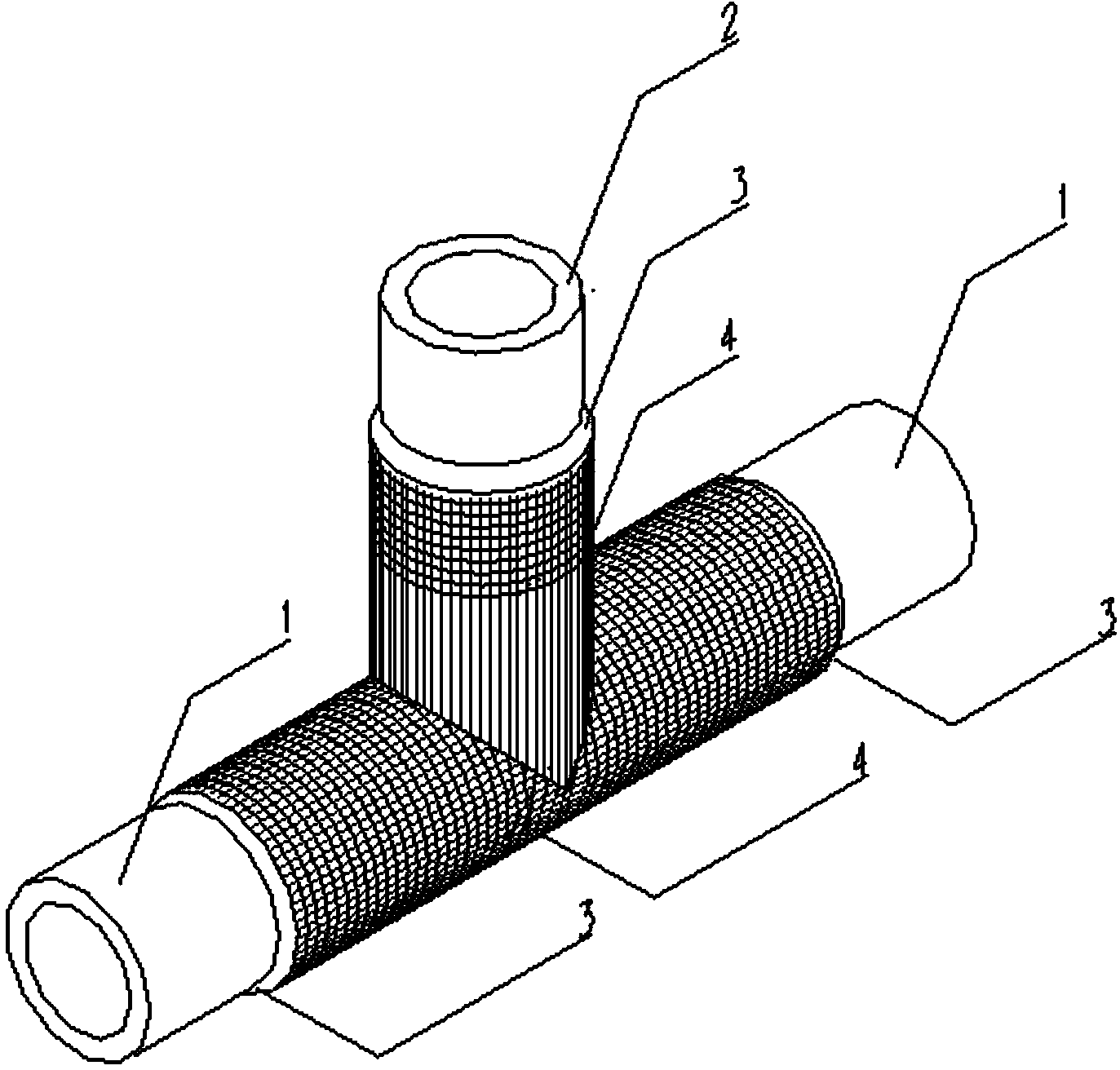

[0024] Such as figure 1 As shown, a steel pipe intersecting node reinforced with carbon fiber composite reinforced materials, including a node steel pipe main pipe 1, a node steel pipe branch pipe 2, a cementing agent 3 and a carbon fiber cloth 4, and the node steel pipe main pipe 1 and the node steel pipe branch pipe 2 are circular or rectangular steel pipes; the intersecting joints of the steel pipes are evenly coated with cement 3, and carbon fiber cloth 4 is pasted and wound on the cement 3, and the carbon fiber cloth 4 wraps the intersecting joints of the steel pipes coated with cement 3.

[0025] The way that the carbon fiber cloth 4 surrounds the intersecting joints of the steel pipes is the whole circumference. The number of layers of the carbon fiber cloth 4 is 1-3 layers. The sticking direction of the carbon fiber cloth 4 is axial and / or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com