Carbon material modified by metal nanoparticles and preparation method thereof

A technology of metal nanoparticles and carbon materials, applied in the direction of metal material coating technology, nanotechnology, nanotechnology, etc., can solve the problems of difficult to achieve the expected effect, damage the structure, etc., achieve weak binding force, controllable size, and easy operation controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a carbon material modified by metal nanoparticles. The specific steps are: grinding graphite into powder, ultrasonically reacting for 8 hours under mixed acid conditions, and preparing a graphite suspension with a concentration of 0.1-0.2 mg / mL with deionized water , and load the graphite suspension on a silicon wafer, and dry it at 50-60°C. Place the silicon wafer loaded with graphite on the sample stage of the ion implanter, and evacuate to 1×10 -2 ~1×10 -3 Pa, using gold as the target material, the accelerating voltage of ion implantation is 1~5KV, and the ion implantation dose is 1×10 15 ~1×10 16 ions / cm 2 , prepared gold nanoparticles modified graphite material.

Embodiment 2

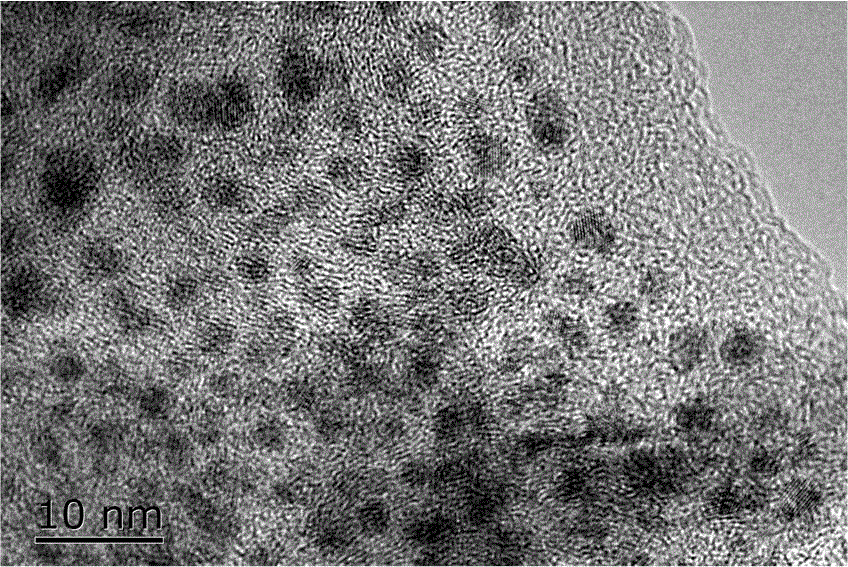

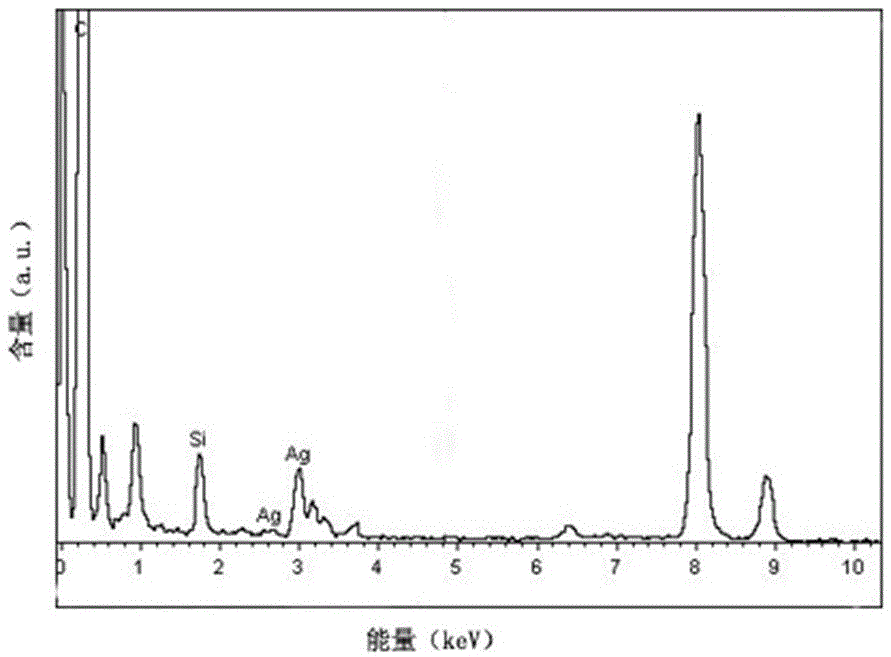

[0029] A method for preparing a metal nanoparticle-modified carbon material, the specific steps of which are as follows: glassy carbon is subjected to ultrasonic reaction for 10 hours under mixed acid conditions, a glassy carbon suspension with a concentration of 0.4-0.5 mg / mL is prepared with deionized water, and Load the glassy carbon suspension on a glass slide and dry it at 50-60°C. Place the glass slide loaded with glassy carbon on the sample stage of the ion implanter, and evacuate to 1×10 -3 ~1×10 -4 Pa, silver is used as the target material, the accelerating voltage of ion implantation is 5~20KV, and the ion implantation dose is 1×10 16 ~1×10 17 ions / cm 2 , the glassy carbon material modified with silver nanoparticles was prepared.

Embodiment 3

[0031] A method for preparing a carbon material modified by metal nanoparticles, the specific steps are: subject carbon powder to ultrasonic reaction for 7 hours under mixed acid conditions, prepare a suspension of carbon powder with a concentration of 0.5-0.6 mg / mL with deionized water, and Load the carbon powder suspension on the silicon wafer and dry it at 50~60°C. Place the silicon wafer loaded with carbon powder on the sample stage of the ion implanter, and evacuate to 1×10 -4 ~1×10 -5 Pa, platinum is used as the target material, the accelerating voltage of ion implantation is 20~50KV, and the ion implantation dose is 1×10 17 ~1×10 18 ions / cm 2 , and the carbon powder material modified with platinum nanoparticles was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com