High impact resistance ultraviolet curing coating combination and use method thereof

A technology for curing coatings and ultraviolet light, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of fragility, difficulty in moving, and easy cracking of the screen, and achieve the goal of increasing yield and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

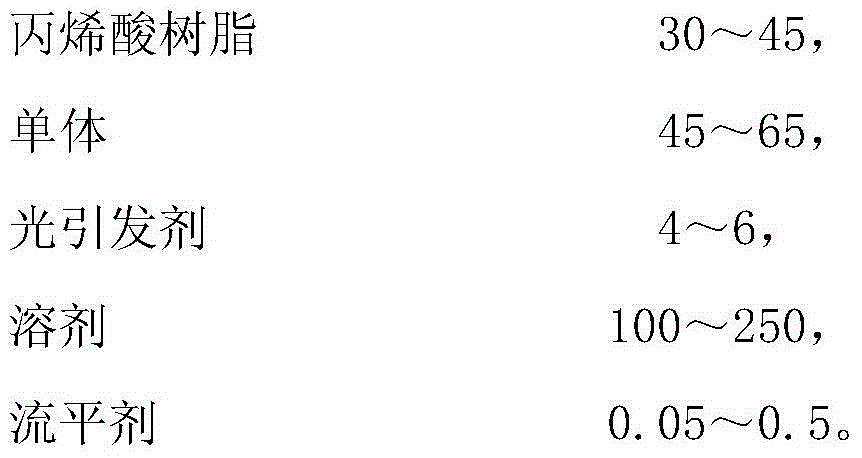

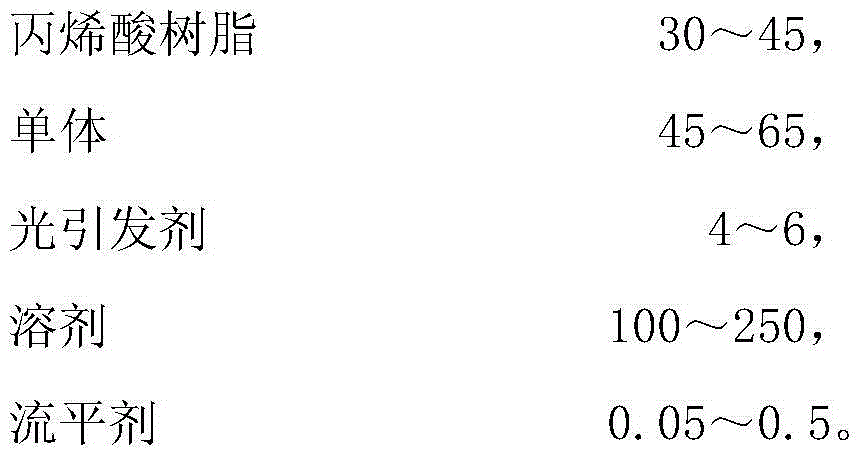

[0019] This embodiment relates to a UV-curable coating composition with high impact resistance, including the components and parts by weight shown in Table 1;

[0020] The coating is under the protection of nitrogen, 900mJ / cm 2 The performance after energy curing is as follows: Hardness PMMA surface 1 kg force 4H, no scratches. 1 kg force HB on the PC surface, no scratches. The light transmittance is 92%, and the impact resistance is 11.3 grams × 100CM without cracking. Scratch resistance is 0000# steel wool 200 grams of force 50 times, no obvious scratches. The glass cracked at 11.3 grams x 50 cm.

[0021] In air, 900mJ / cm 2 The performance after energy curing is as follows: Hardness PMMA surface 1 kg force 3H, no scratches. 1 kg force B on the PC surface, no scratches. The light transmittance is 92%, and the impact resistance is 11.3 grams × 100CM without cracking. The scratch resistance is 0000# steel wool 50 grams force 50 times, the scratches are serious. The glas...

Embodiment 2

[0023] This embodiment relates to a UV-curable coating composition with high impact resistance, including the components and parts by weight shown in Table 1;

[0024] The coating is under the protection of nitrogen, 900mJ / cm 2 The performance after energy curing is as follows: Hardness PMMA surface 1 kg force 4H, no scratches. 1 kg force HB on the PC surface, no scratches. The light transmittance is 92%, and the impact resistance is 11.3 grams × 100CM without cracking. Scratch resistance is 0000# steel wool 200 grams of force 50 times, no obvious scratches. The glass cracked at 11.3 grams x 50 cm.

[0025] In air, 900mJ / cm 2 The performance after energy curing is as follows: Hardness PMMA surface 1 kg force 3H, no scratches. 1 kg force B on the PC surface, no scratches. The light transmittance is 92%, and the impact resistance is 11.3 grams × 100CM without cracking. The scratch resistance is 0000# steel wool 50 grams force 50 times, the scratches are serious. The glas...

Embodiment 3

[0027] This embodiment relates to a UV-curable coating composition with high impact resistance, including the components and parts by weight shown in Table 1;

[0028] The coating is under the protection of nitrogen, 900mJ / cm 2 The performance after energy curing is as follows: Hardness PMMA surface 1 kg force 4H, no scratches. 1 kg force HB on the PC surface, no scratches. The light transmittance is 92%, and the impact resistance is 11.3 grams × 100CM without cracking. Scratch resistance is 0000# steel wool 200 grams of force 50 times, no obvious scratches. The glass cracked at 11.3 grams x 50 cm.

[0029] In air, 900mJ / cm 2 The performance after energy curing is as follows: Hardness PMMA surface 1 kg force 3H, no scratches. 1 kg force B on the PC surface, no scratches. The light transmittance is 92%, and the impact resistance is 11.3 grams × 100CM without cracking. The scratch resistance is 0000# steel wool 50 grams force 50 times, the scratches are serious. The glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com