Coating composition for hydrophilic treatment of air-conditioning parallel flow heat exchanger

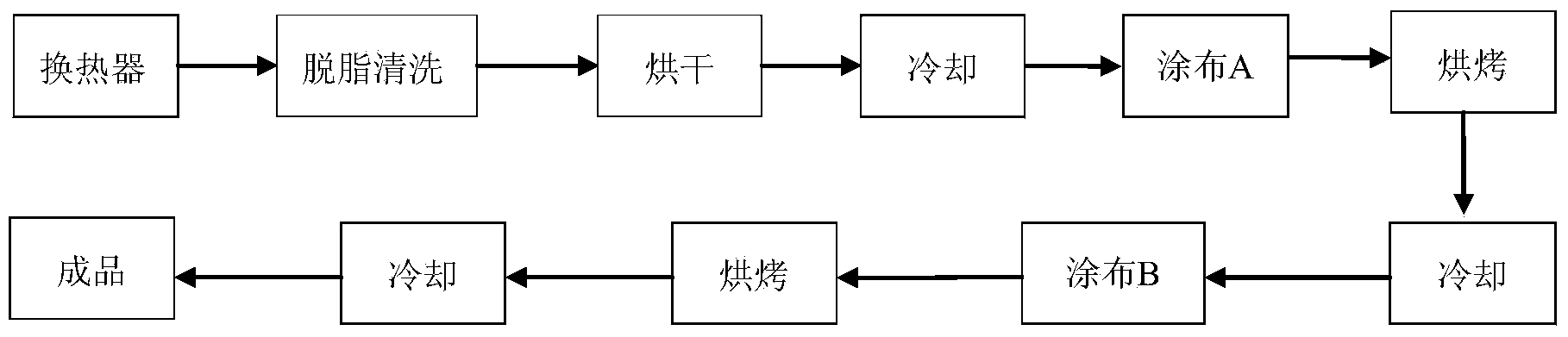

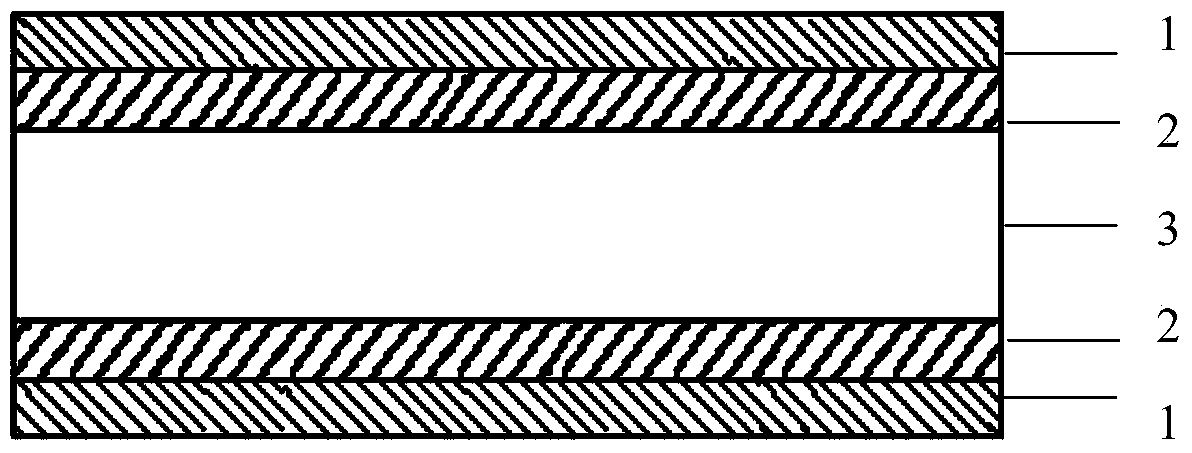

An exchanger and hydrophilization technology, which is applied in the field of coating composition and its preparation for hydrophilization treatment of air-conditioning parallel flow heat exchangers, can solve the problems of construction adaptability and performance that are difficult to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

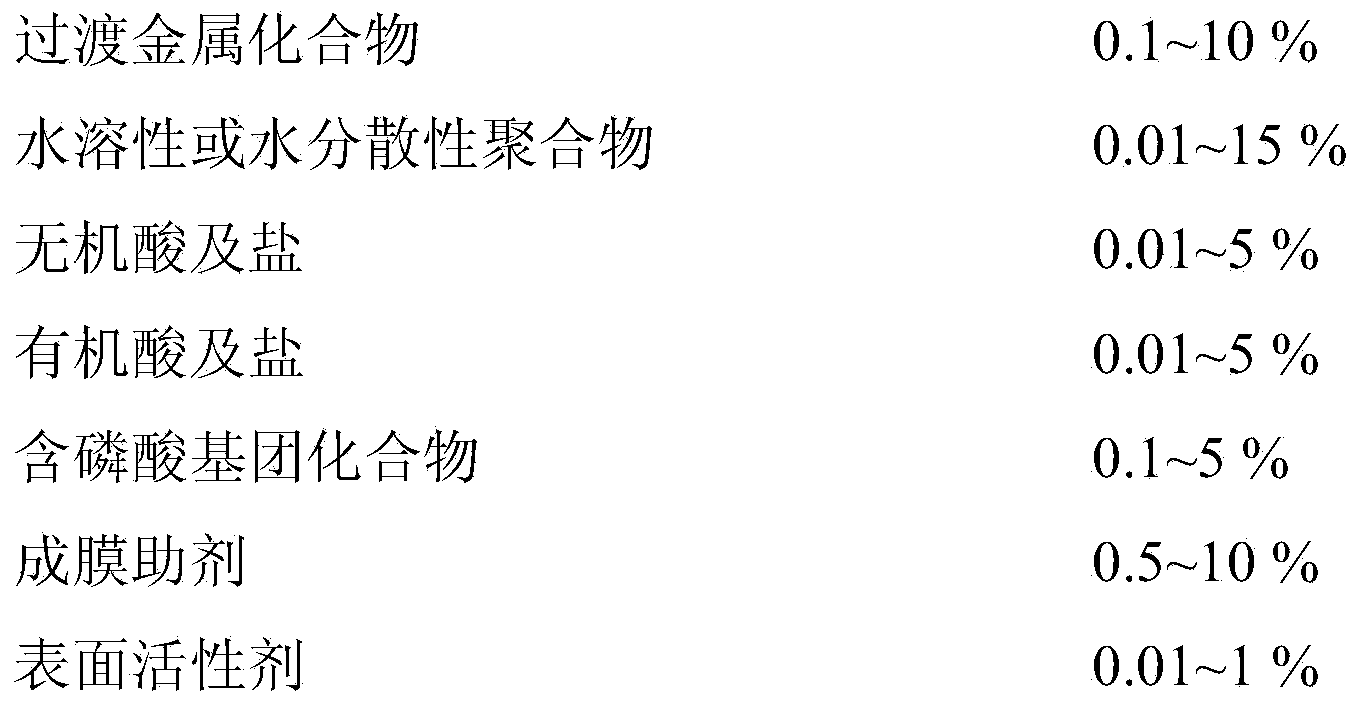

[0092] Coating A consists of the following components (in g):

[0093]

[0094] The total amount of the above components is 100.

[0095] Acrylic resin is composed of the following components by mass percentage

[0096] Monomer 80

[0097] Azobisisobutyronitrile 5

[0098] Mixed solvents 15

[0099] The preparation process of acrylic resin is as follows: mix the monomers (methacrylic acid, methyl methacrylate, butyl acrylate, and styrene in a mass ratio of 2:3:3:2), and add azobisisobutyronitrile Mix to obtain a mixture; add a mixed solvent of butanol, ethylene glycol butyl ether, and isopropanol (the mixing mass ratio is 3:5:2) to the reaction kettle, heat up to 80°C and reflux, add the above mixture dropwise for 2 hours After the internal dropwise addition is completed, the temperature is lowered and the material is discharged after 3 hours of heat preservation, and the resin has a solid content of 48%;

[0100]The preparation process of coating A is as follows: take...

Embodiment 2

[0112] Coating A consists of the following components (in g):

[0113]

[0114]

[0115] The total amount of the above components is 100.

[0116] Acrylic resins consist of the following components (in grams):

[0117] Monomer 30

[0118] Benzoyl Peroxide 1.5

[0119] n-butanol balance

[0120] The total amount of the above components is 100.

[0121] The preparation process of acrylic resin is as follows: the preparation of coating A: monomer acrylic acid, butyl methacrylate, hydroxyethyl acrylate are mixed by the mass ratio of 6:2:2, add benzoyl peroxide and continue to mix; Add n-butanol into the kettle, raise the temperature to 110°C and reflux, add the mixture of the above-mentioned monomer and initiator dropwise, and drop evenly for 3 hours. Material, resin solid content 30%;

[0122] The preparation process of paint A is as follows: take acrylic resin, add full methyl etherified amino resin and ammonium dodecylbenzene sulfonate, finally add wetting agent AQ3...

Embodiment 3

[0131] Coating A consists of the following components (in g):

[0132]

[0133] The total amount of the above components is 100.

[0134] Preparation of coating A: CrCl 3 Dissolve in water to prepare a 10% solution, add 0.01g tartaric acid, 0.1g phosphoric acid, 3g ethylene glycol monobutyl ether, 4g ethanol, 1g hydrofluoric acid (40%), and 0.3g fluorosurfactant F-1157 , the remaining water, and finally add 12g of non-ionic polyurethane resin PUD-1110 (35%, Shanghai Sisheng Polymer Material Co., Ltd.), stir well and set aside.

[0135] Coating B consists of the following components (in g):

[0136]

[0137] The total amount of the above components is 100.

[0138] Organic resin is composed of the following components (in g):

[0139]

[0140] The preparation process of the organic resin is as follows: the monomer acrylic acid, N-methylol acrylamide, and diacetone acrylamide are mixed uniformly in the ratio of 6:3:1 (mass ratio); water and 2% thiosulfuric acid are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com