Rubber strippable paint and preparation method thereof

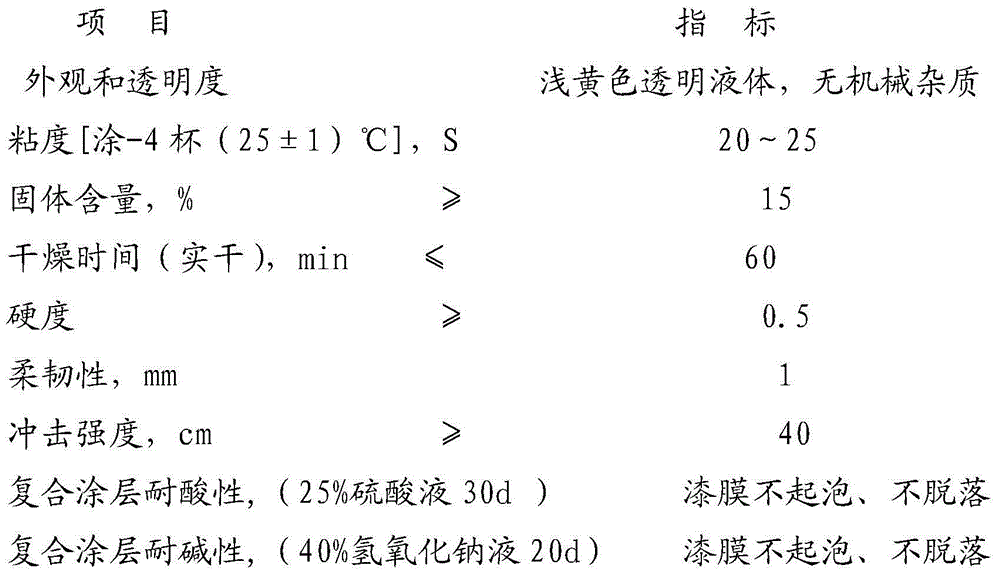

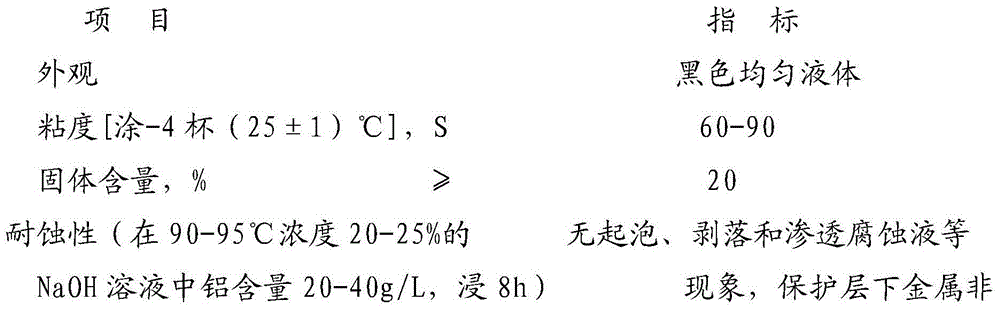

A technology of rubber and paint stripping, applied in the field of coatings, can solve problems such as the erosion ratio not meeting user requirements, general corrosion resistance, coating blistering, etc., and achieve good erosion ratio, excellent alkali resistance, and strong paint film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Rubber mixing:

[0033] ①Warm 5g of LDJ-230 neoprene and 10g of U.S. W-type neoprene in a warm room at 40-50°C for 10 hours, cut them into small pieces with a rubber cutter, and place the cut rubber pieces while they are soft with a roller distance of Roll the material on a 1mm rubber mixing machine, turn on enough cooling water, then adjust the roll distance to 0.5mm, place the rolled rubber on the rubber mixing machine for 2-3 times to soften, and then adjust the roll distance to 0.1-0.2 mm continue to roll the material 15-20 times to improve the plasticity of the rubber; Adjust the roller distance to 0.1-0.2mm and continue to roll the material 10 times, so that the added raw materials are dispersed evenly. The dispersion of each material is checked by tearing the mixed rubber into a film. It is uniform and transparent. If there are no raw material particles, it is qualified. Roll out the film to 1mm and cool it down. After the mixed rubber is cooled, cut it into ...

Embodiment 2

[0038] 1. Rubber mixing:

[0039] ①Warm 20g of butadiene rubber in a warm room at 40-50°C for 10 hours, cut it into small pieces with a rubber cutter, place the cut rubber piece on a rubber mixing machine with a roll distance of 1mm while it is soft, and cool it fully water, then adjust the roll distance to 0.5mm, place the rolled rubber on the rubber mixing machine for 2-3 times to soften, then adjust the roll distance to 0.1-0.2mm and continue rolling 15-20 times to improve Plasticity of rubber; ② Adjust the roll distance to 1mm, add 3g of magnesium oxide, 0.5g of anti-aging agent butyl, 0.5g of stearic acid, 1g of zinc oxide to roll the rubber, and then adjust the roll distance to 0.1-0.2mm to continue rolling for 10 Second, make the added raw materials disperse evenly. The dispersion of each material is checked by tearing the mixed rubber into a film. It is uniform and transparent, and there are no raw material particles. It is qualified. Adjust the roller distance to 1mm ...

Embodiment 3

[0044] 1. Rubber mixing:

[0045] ①Warm 10g of styrene-butadiene rubber and 8g of nitrile rubber in a warm room at 40-50°C for 10 hours, cut them into small pieces with a rubber cutter, and place the cut rubber pieces on a rubber mixing machine with a roll distance of 1mm while they are soft. Turn on the cooling water enough, then adjust the roll distance to 0.5mm, put the rolled rubber on the rubber mixing machine for 2-3 times to soften, then adjust the roll distance to 0.1-0.2mm and continue rolling for 15- 20 times to improve the plasticity of the rubber; ② Adjust the roller distance to 1mm, add 2g of magnesium oxide, 0.3g of anti-aging agent D, 0.3g of stearic acid, 2g of zinc oxide to roll the rubber, and then adjust the roller distance to 0.1-0.2 mm Continue to roll the material 10 times to make the added raw materials disperse evenly. The dispersion of each material is inspected by tearing the mixed rubber into a film. It is uniform and transparent. If there are no raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com