Aqueous bi-component acrylic acid-polyurethane resin and preparation method thereof

A polyurethane resin and acrylic technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as system failure, formation of bubbles or pinholes, and performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In Example 1, the water-based two-component acrylic-polyurethane resin is prepared by mixing A composition and B composition;

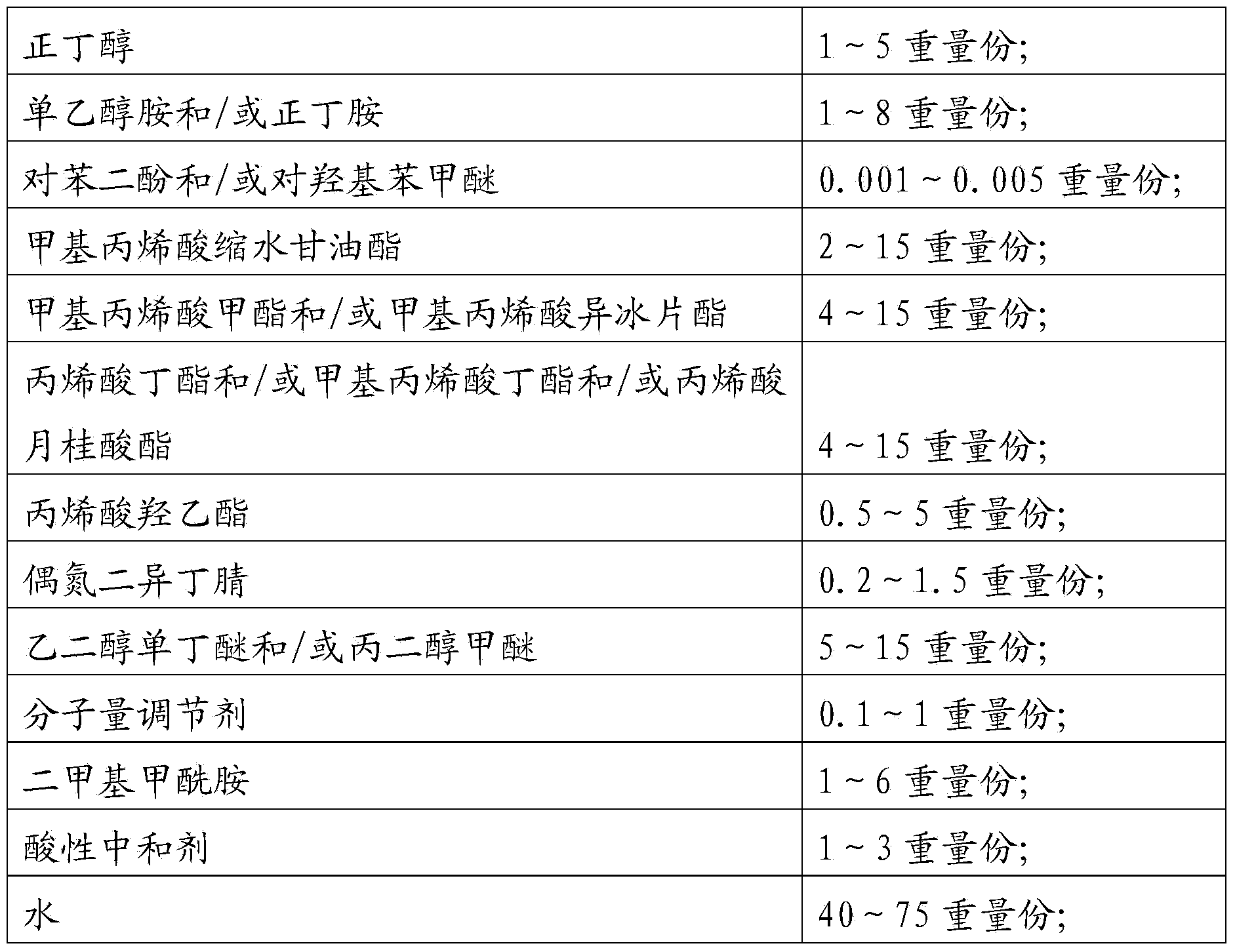

[0023] The A composition consists of the following components:

[0024] Butanol

50g;

Monoethanolamine

61g;

Quinol

0.05g;

140g;

65g;

65g;

Hydroxyethyl Acrylate

10g;

[0025] Azobisisobutyronitrile

6g;

Ethylene glycol monobutyl ether

80g;

Molecular weight regulator (tert-dodecyl mercaptan)

4g;

24g;

Acid neutralizer (formic acid)

13.6g;

water

600g;

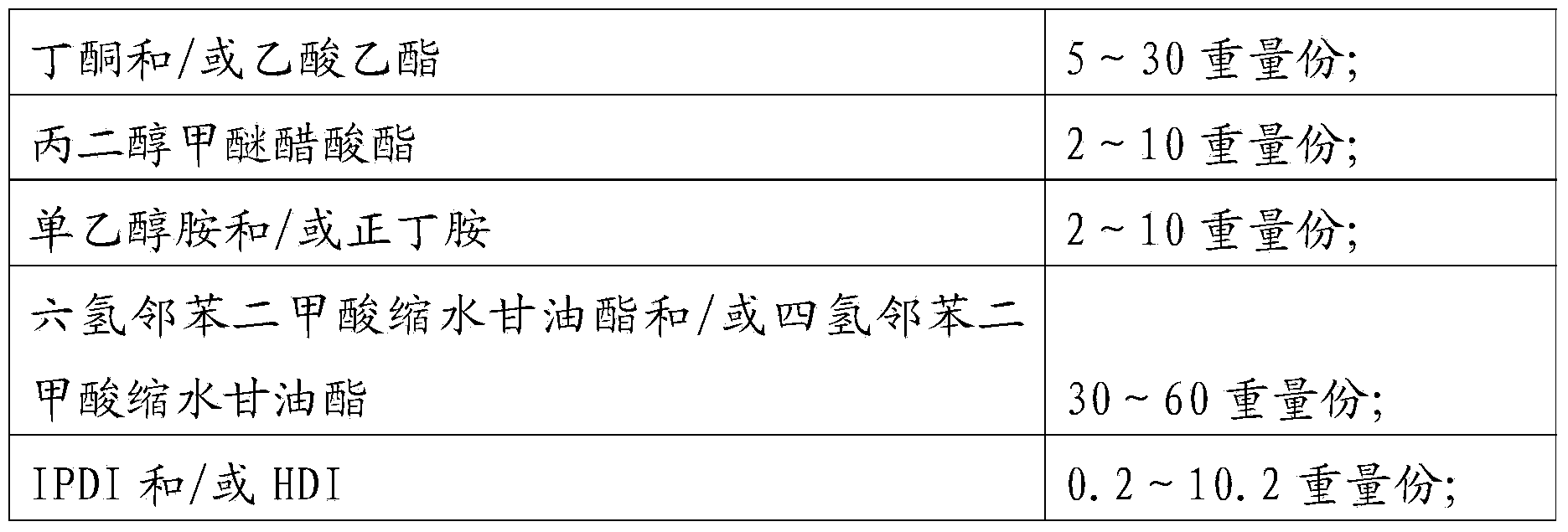

[0026] The B composition consists of the following components:

[0027] butanone

40g;

Propylene glycol methyl ether acetate

10g;

22.8g;

Glycidyl Hexahydrophthalate

200g;

IPDI

34.6g;

Ethyle...

Embodiment 2

[0034] In embodiment 2, water-based two-component acrylic-urethane resin is prepared by mixing A composition and B composition;

[0035] The A composition consists of the following components:

[0036]

[0037]

[0038] The B composition consists of the following components:

[0039]

[0040] The preparation process of waterborne two-component acrylic acid-polyurethane resin is:

[0041] Preparation of component A: Add 15g of propylene glycol methyl ether, n-butanol, glycidyl methacrylate and p-hydroxyanisole into a 500ml reactor, heat to 50°C, add monoethanolamine dropwise, and finish dropping in 1 to 2 hours. Keep warm at 50°C for 2 hours; heat up to 70°C, keep warm for 3 hours, and discharge. Take out 82.8g and methyl methacrylate, butyl acrylate, laurate acrylate, hydroxyethyl acrylate, molecular weight modifier, azobisisobutyronitrile, dimethylformamide to prepare a mixed solution; react in another 1000ml Add 80g of propylene glycol methyl ether into the conta...

Embodiment 3

[0046] In embodiment 3, water-based two-component acrylic acid-urethane resin is prepared by mixing A composition and B composition;

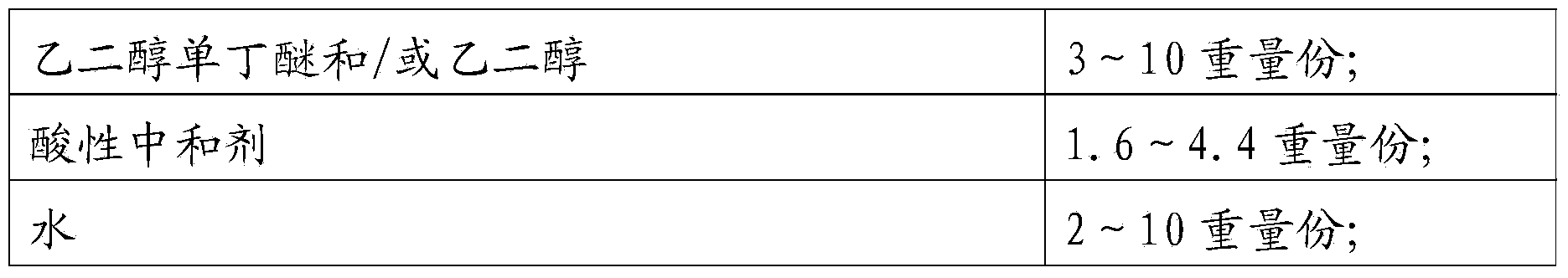

[0047] The A composition consists of the following components:

[0048]

[0049] The B composition consists of the following components:

[0050] butanone

40g;

Propylene glycol methyl ether acetate

8g;

22.8g;

Glycidyl Tetrahydrophthalate

200g;

HDI

26.2g;

Ethylene glycol

15g;

Acid neutralizer (lactic acid)

14.4g;

water

10g;

[0051] The preparation process of waterborne two-component acrylic acid-polyurethane resin is:

[0052] Preparation of component A: Add 50g of ethylene glycol monobutyl ether, glycidyl methacrylate and hydroquinone into a 500ml reactor, heat to 50°C, add monoethanolamine dropwise, drop it in 1 to 2 hours, and finish at 50°C Keep warm for 2 hours; heat up to 70°C, keep warm for 3 hours, and discharge. Take out 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com