Mineral processing technology for reducing, roasting, iron extraction and impurity removal of limonite

A limonite and roasting technology, applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low iron grade in concentrate, complicated beneficiation process and many operating conditions, etc. The effect of high chemical rate and reduced grinding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

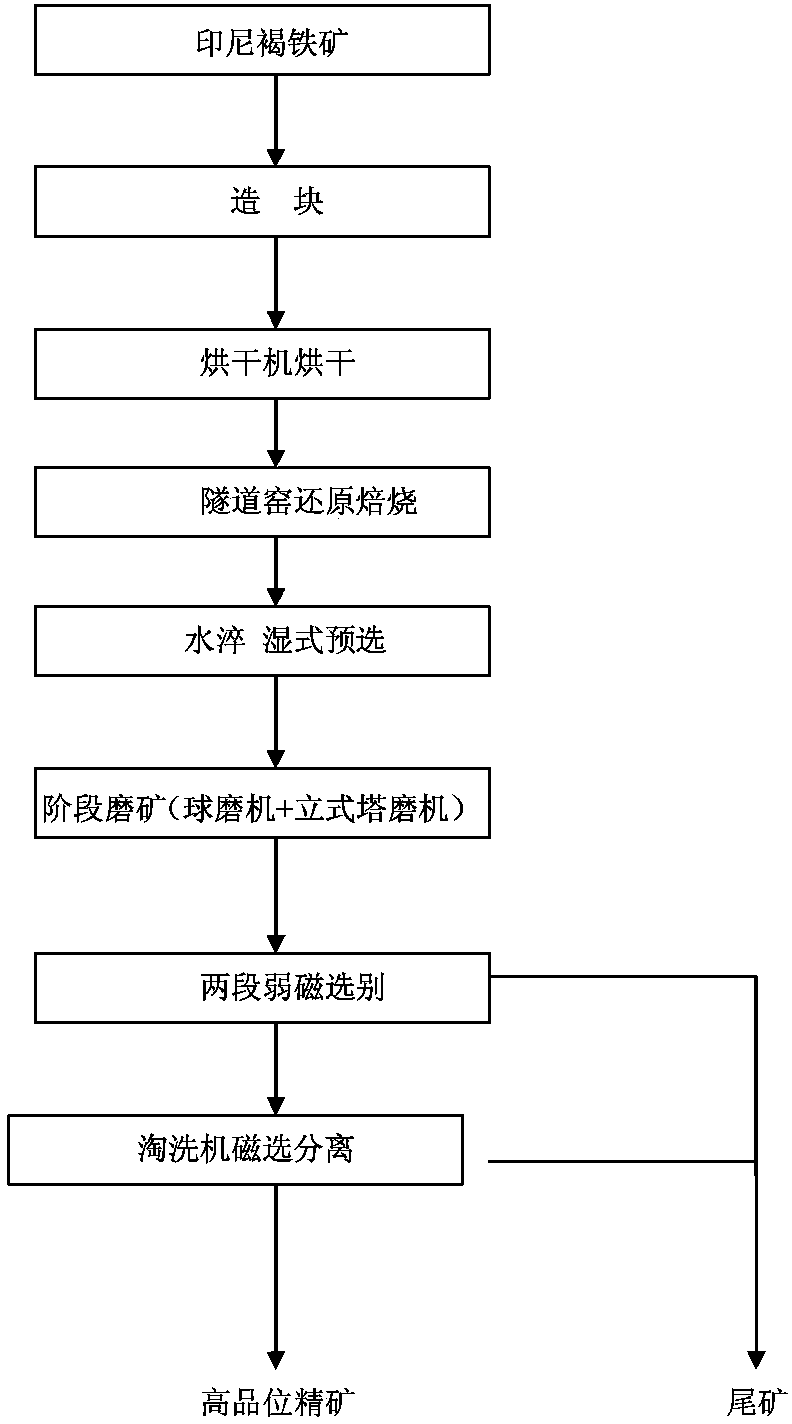

Method used

Image

Examples

Embodiment 1

[0030] The main chemical composition of the Indonesian limonite processed by the present invention is: TFe 42.0%, the raw material ratio of the agglomeration mixture: Indonesian limonite 92.0%, coal powder 5.0%, binder cassava starch 1%, additive 2.0% , The additive is a mixture of calcium oxide, sodium carbonate and sodium sulfate, the weight percentage of calcium oxide, sodium carbonate and sodium sulfate is 30%: 30%: 40%. After crushing, mix and agglomerate, put it into the dryer, dry at 250°C for 7 minutes, and then put the dried material into the tunnel kiln for reduction and roasting, the roasting temperature is 1000°C, and the high-temperature roasting time is 6 hours. After roasting, the product is quenched and cooled in water, and sieved. The diameter of the sieve hole is 10 mm. The product under the sieve is wet pre-selected, and the product on the sieve is crushed by a crusher to a size below 10 mm. % of the tailings, the concentrate pre-selected by the wet pre-sele...

Embodiment 2

[0032] The main chemical composition of the Indonesian limonite processed by the present invention is: TFe 45.0%, the raw material ratio of the block mixture: Indonesian limonite 81.0%, coal powder 13.0%, binder cassava starch 4%, additive 2.0% , the additive is a mixture of calcium oxide, sodium carbonate and sodium sulfate, the weight percentage of calcium oxide, sodium carbonate and sodium sulfate is 30%: 30%: 40%). After crushing, mix and make agglomerates, put it into the dryer, dry at 300°C for 6 minutes, and then reduce the dried material to roasting at 1100°C, high-temperature roasting time for 5 hours, and reduce roasting After the end, water quenching and cooling, and then sieving, the sieve diameter of the wet pre-screening screen is 10 mm, the product under the screen is crushed to less than 10 mm by the crusher, and the wet pre-screening yield is 20.45%. , Qualified tailings with an iron grade of 7.88%, feed the concentrate pre-selected by the wet pre-separation m...

Embodiment 3

[0034]The main chemical composition of the Indonesian limonite processed by the present invention is: TFe 50.0%, the raw material ratio of the agglomerate mixture: 90.0% of Indonesian high-alumina limonite, 7.0% of coal powder, 2.0% of adhesive cassava starch, adding Binder 1.0%, the additive is a mixture of calcium oxide, sodium carbonate and sodium sulfate, its calcium oxide, sodium carbonate, sodium sulfate weight percentage is 30%: 30%: 40%, mixed after crushing, agglomeration , put it into the dryer, dry at 380°C for 5 minutes, and then roast the dried material at a temperature of 900°C for 6 hours at a high temperature. The sieve hole diameter of the pre-screening screen is 10 mm. The product under the screen is crushed by the crusher to less than 10 mm. The wet pre-screening, the wet pre-selection discards the qualified tailings with a yield of 16.45% and an iron grade of 8.18%. The concentrate pre-selected by the concentrator is fed into the ball mill for a stage of we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com