Phosphate rock flotation collector and preparation method thereof

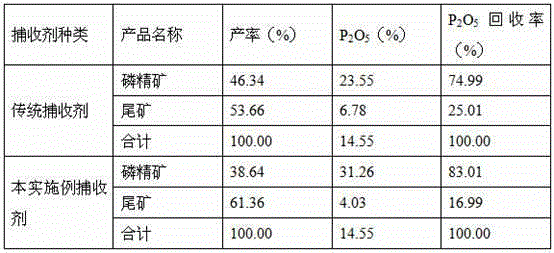

A collector and phosphate rock technology, applied in flotation, solid separation, etc., to achieve the effects of improving concentrate grade and recovery rate, improving economic benefits, and reducing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

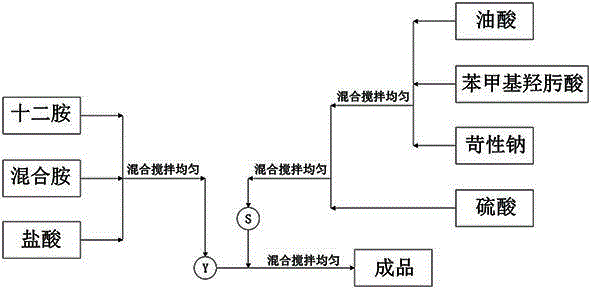

[0049] A phosphate rock flotation collector is prepared from components in the following weight ratios:

[0050] Y 20,

[0051] S 80,

[0052] Described Y is made up of the component of following weight ratio:

[0053] Dodecylamine 60,

[0054] Mixed amine 20,

[0055] Hydrochloric acid 20,

[0056] Described S is made up of the component of following weight ratio:

[0057] Oleic Acid 40,

[0058] Benzyl hydroxamic acid 20,

[0059] caustic soda 30,

[0060] sulfuric acid 10,

[0061] Among the above raw materials, dodecylamine {CH 3 —(CH 2 ) 10 —CH 2 NH 2}, mixed amine {R—NH 2}, R is C 17~20 Alkyl, oleic acid {C 17 h 33 COOH}, benzyl hydroxamic acid {C 7 h 7 NO 2}, hydrochloric acid {HCl}, caustic soda {NaOH}, and sulfuric acid are commercially available products.

[0062] Preferably, the purity of the dodecylamine ≥ 95%, the purity of the mixed amine ≥ 95%, the mass percentage concentration of the hydrochloric acid ≥ 35%, the purity of the oleic acid ≥ 9...

Embodiment 2

[0074] A phosphate rock flotation collector is prepared from components in the following weight ratios:

[0075] Y 70,

[0076] S 30,

[0077] Described Y is made up of the component of following weight ratio:

[0078] Dodecylamine 30,

[0079] Mixed amine 40,

[0080] Hydrochloric acid 30,

[0081] Described S is made up of the component of following weight ratio:

[0082] Oleic acid 20,

[0083] Benzyl hydroxamic acid 40,

[0084] caustic soda 20,

[0085] sulfuric acid 20,

[0086] Among the above raw materials, dodecylamine {CH 3 —(CH 2 ) 10 —CH 2 NH 2}, mixed amine {R—NH 2}, R is C 17~20 Alkyl, oleic acid {C 17 h 33 COOH}, benzyl hydroxamic acid {C 7 h 7 NO 2}, hydrochloric acid {HCl}, caustic soda {NaOH}, and sulfuric acid are commercially available products.

[0087] Preferably, the purity of the dodecylamine ≥ 95%, the purity of the mixed amine ≥ 95%, the mass percentage concentration of the hydrochloric acid ≥ 35%, the purity of the oleic acid ≥ 9...

Embodiment 3

[0095] A phosphate rock flotation collector is prepared from components in the following weight ratios:

[0096] Y 40,

[0097] S60,

[0098] Described Y is made up of the component of following weight ratio:

[0099] Dodecylamine 45,

[0100] Mixed amine 35,

[0101] Hydrochloric acid 25,

[0102] Described S is made up of the component of following weight ratio:

[0103] Oleic Acid 30,

[0104] Benzyl hydroxamic acid 30,

[0105] caustic soda 25,

[0106] sulfuric acid 15,

[0107] Among the above raw materials, dodecylamine {CH 3 —(CH 2 ) 10 —CH 2 NH 2}, mixed amine {R—NH 2}, R is C 17~20 Alkyl, oleic acid {C 17 h 33 COOH}, benzyl hydroxamic acid {C 7 h 7 NO 2}, hydrochloric acid {HCl}, caustic soda {NaOH}, and sulfuric acid are commercially available products.

[0108] Preferably, the purity of the dodecylamine ≥ 95%, the purity of the mixed amine ≥ 95%, the mass percentage concentration of the hydrochloric acid ≥ 35%, the purity of the oleic acid ≥ 95...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com