Low-sugar highly nutrient gluten-free bread production method

A gluten-free, high-nutrition technology, applied in dough processing, pre-baking dough processing, baking, etc., can solve problems such as inability to lock moisture, single raw materials, and fragility, and achieve a delicate and not rough taste, strong anti-oxidation Active, permeability-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

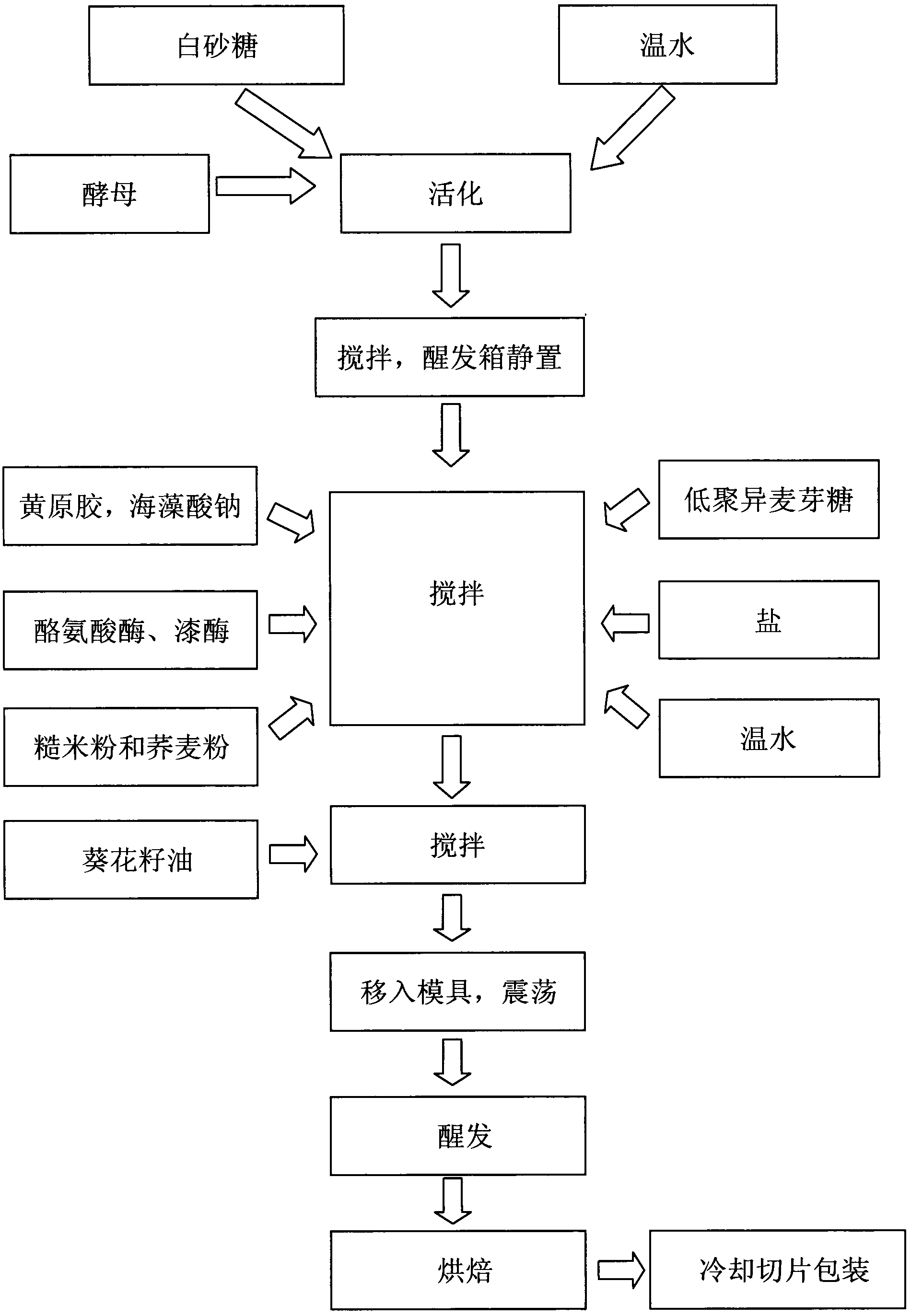

Image

Examples

Embodiment 1

[0026] A low-sugar and high-nutrition gluten-free bread whose formula is 225g brown rice and 25g buckwheat flour. Other additives are: Taikoo white granulated sugar 5g, Shandong Tianjiao Biotechnology Co., Ltd. Isomaltooligosaccharide (IMO50) 10g, salt 5g, Fulinmen sunflower oil 15g, Angel yeast 2.5g, Henan Xingyuan Chemical Products Co., Ltd. Huangyuan Gel 0.8g, Qingdao Mingyue Seaweed Company Sodium Alginate 0.5g, Shanghai Hengyuan Biotechnology Co., Ltd. Tyrosinase 20ppm, and Ningxia Xiasheng Industrial Group Co., Ltd. Laccase 30ppm.

[0027] The production process is as follows:

[0028] First, the brown rice and buckwheat are superfinely pulverized to obtain whole brown rice flour and buckwheat flour with a particle size of 100 meshes. Then dissolve 5 g of white granulated sugar in 100 g of warm water, stir to dissolve, add 2.5 g of yeast and stir for 1 min, put it in a proofing box at 38°C and 85% humidity for 4 min, then take it out. Mix 225g brown rice with 25g buckwheat ...

Embodiment 2

[0030] A low-sugar and high-nutrition gluten-free bread whose formula is 200g brown rice and 50g buckwheat flour. Other additives are: Taikoo white granulated sugar 5g, Shandong Tianjiao Biotechnology Co., Ltd. Isomaltooligosaccharide (IMO50) 10g, salt 5g, Fulinmen sunflower oil 15g, Angel yeast 2.5g, Henan Xingyuan Chemical Products Co., Ltd. Huangyuan Gel 0.8g, Qingdao Mingyue Seaweed Company Sodium Alginate 0.5g, Shanghai Hengyuan Biotechnology Co., Ltd. Tyrosinase 20ppm, and Ningxia Xiasheng Industrial Group Co., Ltd. Laccase 30ppm.

[0031] The production process is as follows:

[0032] First, the brown rice and buckwheat are superfinely pulverized to obtain whole brown rice flour and buckwheat flour with a particle size of 100 meshes. Then dissolve 5 g of white granulated sugar in 100 g of warm water, stir to dissolve, add 2.5 g of yeast and stir for 1 min, put it in a proofing box at 38°C and 85% humidity for 4 min, and take it out. Mix 200g brown rice with 50g buckwheat f...

Embodiment 3

[0034] A low-sugar and high-nutrition gluten-free bread whose formula is 175g brown rice and 75g buckwheat flour. Other additives are: Taikoo white granulated sugar 5g, Shandong Tianjiao Biotechnology Co., Ltd. Isomaltooligosaccharide (IMO50) 10g, salt 5g, Fulinmen sunflower oil 15g, Angel yeast 2.5g, Henan Xingyuan Chemical Products Co., Ltd. Huangyuan Gel 0.8g, Qingdao Mingyue Seaweed Company Sodium Alginate 0.5g, Shanghai Hengyuan Biotechnology Co., Ltd. Tyrosinase 20ppm, and Ningxia Xiasheng Industrial Group Co., Ltd. Laccase 30ppm.

[0035] Angel Yeast 2.5g, Henan Xingyuan Chemical Products Co., Ltd. Xanthan Gum 0.8g, Qingdao Mingyue Seaweed Company Sodium Alginate 0.5g, Shanghai Hengyuan Biotechnology Co., Ltd. Tyrosinase 20ppm, and Ningxia Xiasheng Industrial Group Co., Ltd. paint Enzyme 30ppm.

[0036] The production process is as follows:

[0037] First, the brown rice and buckwheat are superfinely pulverized to obtain whole brown rice flour and buckwheat flour with a part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com