Si nanorod/qds composite silicon-based solar cell and preparation method thereof

A solar cell, cell technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of improving optoelectronic performance, good stability, and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

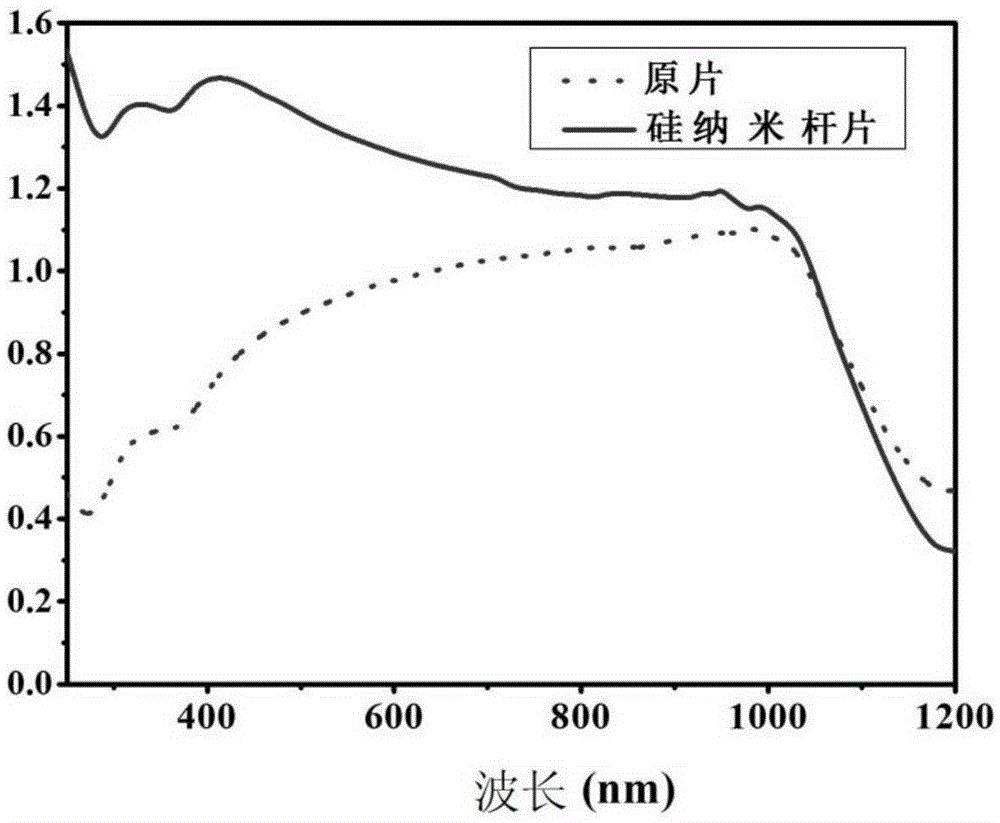

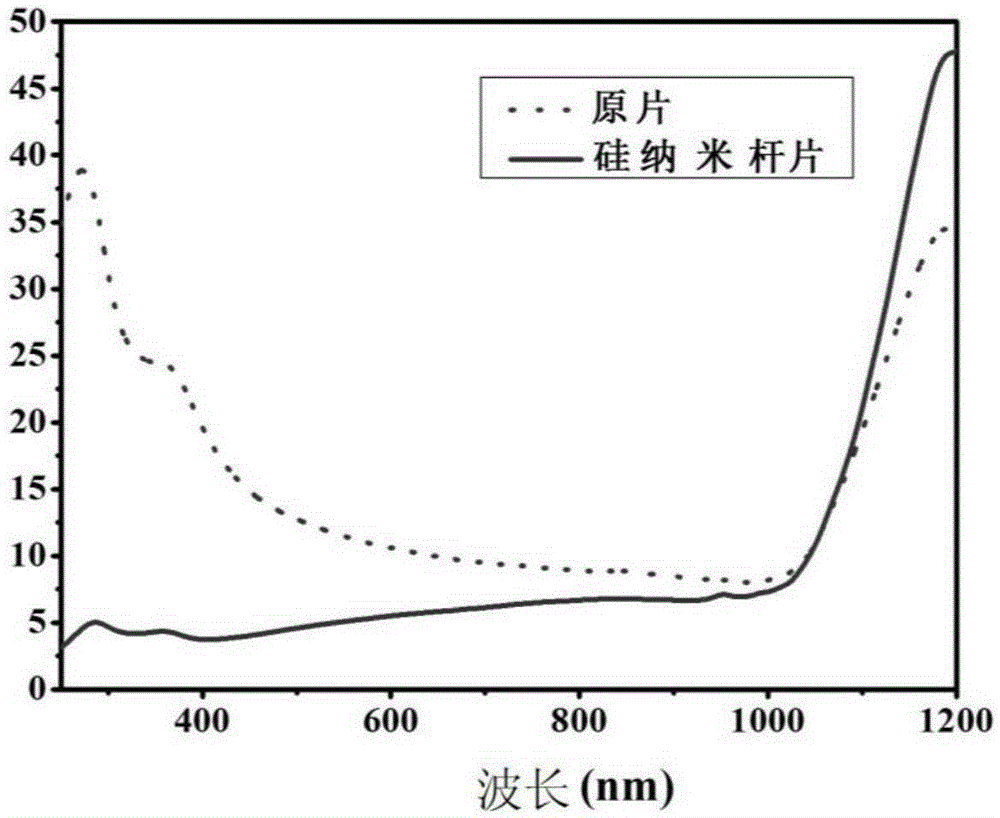

AI Technical Summary

Problems solved by technology

Method used

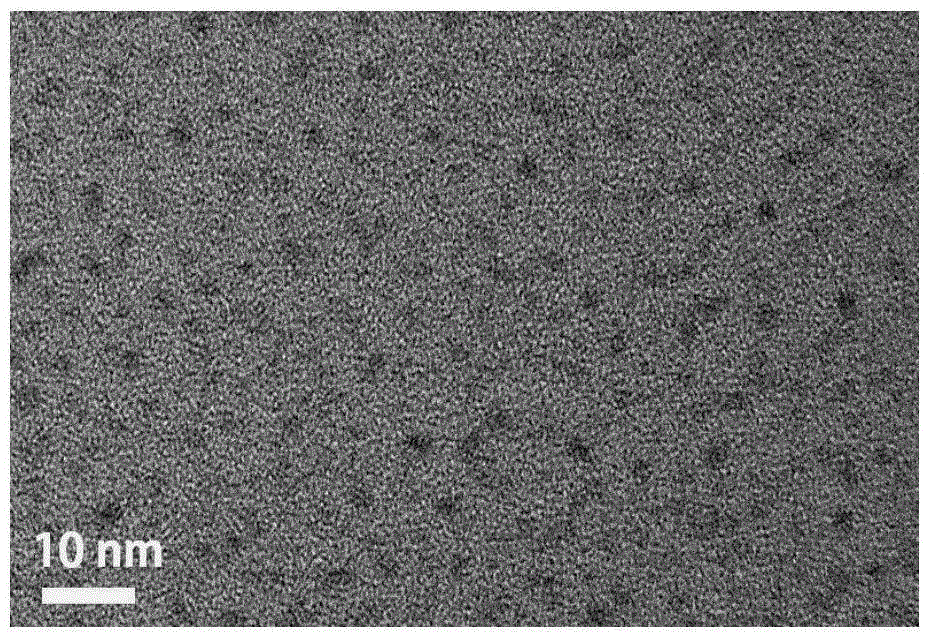

Image

Examples

Embodiment 1

[0030] (a) Dip the silicon-based cell into an anhydrous ethanol solvent for ultrasonic cleaning for 20 seconds, and then immerse it in twice distilled water for ultrasonic cleaning for 2 minutes.

[0031] (b) Prepare a mixed solution of 0.002mol / L silver nitrate and 0.5mol / LHF, and immerse the silicon wafer for 30s.

[0032] (c) configure 0.4mol / LH 2 o 2 , 0.5mol / LHF mixed solution, immerse the silicon chip for 30s, and ultrasonically clean it with concentrated nitric acid for 3min.

[0033] (d) configure 0.005mol / L lead acetate solution; add 0.01mol / L 3-mercaptopropionic acid; add 2×10 -4 mol / L cetyltrimethylammonium bromide to obtain the precursor solution. Prepare 0.005mol / L sulfide amine solution, the volume is the same as the lead acetate solution, slowly drop into the precursor solution at a rate of 20s.

[0034] (e) Immerse the treated silicon-based cell in the quantum dot colloid solution for 30s, pull it slowly at a speed of 0.5cm / s, and dry it slowly with a hair ...

Embodiment 2

[0037] This example differs from Example 1 in that: step b) the metal source is silver acetate with a concentration of 0.005 mol / L.

Embodiment 3

[0039] This example differs from Example 1 in that: step b) the metal source is ferric nitrate with a concentration of 0.005 mol / L. Step c) H 2 o 2 The concentration is 0.3mol / L, and the concentration of HF is 0.6mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com