Hydrophobic polymer graft modified acrylamide polymer and preparation method thereof

An acrylamide-based, hydrophobic polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of temperature resistance, salt resistance, aging resistance and poor displacement effect, etc., to achieve enhanced oil recovery , improve the effect of heat resistance and salt resistance, not easy to curl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Inject 0.10mol 1-hydroxyl-2,2,5-trimethyl-3-(1-phenylethoxy)-4-phenyl-3-azahexane, 0.12mol di Cumene and 0.8mol N,N-dimethylacrylamide reacted at 87°C for 6 hours, then added isopropanol to terminate the reaction, and precipitated with ether, the obtained hydrophobic association poly-N,N with a molecular weight of 770 -Dimethacrylamide homopolymer. 0.08g of the obtained polymer and 2.2g of polyacrylamide with a viscosity-average molecular weight of 28.5 million were dispersed in 97g of potassium carbonate aqueous solution (pH=8.0) under strong stirring, and graft copolymerization occurred under the action of reflux , to obtain the graft modified polymer polyacrylamide-g-poly N, N-dimethylacrylamide.

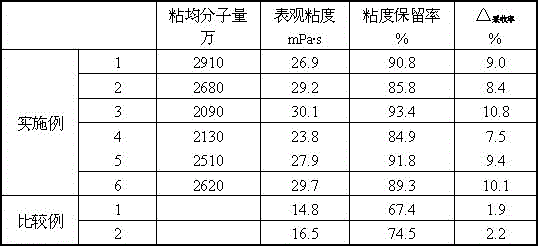

[0021] Use the following methods or standards to test the structure and performance of the grafted modified polyacrylamide obtained by the hydrophobic polymer: measure the intrinsic viscosity of the polymer according to GB / T12005.10-92 polyacrylamide molecular weight dete...

Embodiment 2

[0024] Inject 0.13mol 1-chloro-2,5-dimethyl-3-(1-phenylethoxy)-4-phenyl-3-azahexane, 0.15mol benzoyl peroxide into the dry reaction flask After reacting with 0.25mol N-n-dodecyl acrylamide at 75°C for 7 hours, adding isopropanol to terminate the reaction, and precipitating with ether, a hydrophobic association poly-N-n-dodecyl group with a molecular weight of 500 was obtained. Acrylamide homopolymer. Gained copolymer 0.06g and 1.98g viscosity-average molecular weight are 26,700,000 poly(acrylamide-r-2-acrylamido-2-sodium methylpropanesulfonate) (degree of hydrolysis 18.2%), under strong stirring , dispersed in 98g potassium bicarbonate aqueous solution (pH = 10.0), under the action of reflux, graft copolymerization reaction occurs to obtain graft modified polymer poly(acrylamide-r-2-acrylamide-2-methane Sodium propane sulfonate)-g-poly N-n-dodecyl acrylamide.

[0025] The structure and properties of the hydrophobic polymer graft-modified acrylamide polymer obtained were test...

Embodiment 3

[0027] Inject 0.11mol 1-amino-2,5,5-trimethyl-3-(1-phenylethoxy)-4-phenyl-3-azahexane, 0.125mol isopropyl Benzene hydroperoxide, 0.2mol N-tert-butylacrylamide and 0.1mol N-phenylacrylamide were reacted at 92°C for 7 hours, and isopropanol was added to terminate the reaction. After precipitation with ether, a hydrophobic olefin with a molecular weight of 350 was obtained. Poly(N-tert-butylacrylamide-r-N-phenylacrylamide) random copolymer. 0.05 g of the obtained copolymer and 1.7 g of ultra-high molecular weight polyacrylamide with a viscosity-average molecular weight of 17.2 million were dispersed in 99 g of potassium hydroxide aqueous solution (pH=9.8) under the action of strong stirring, and contact occurred under the action of reflux. Branch copolymerization reaction to obtain graft modified polymer polyacrylamide-g-poly(N-tert-butylacrylamide-r-N-phenylacrylamide).

[0028] The structure and properties of the hydrophobic polymer graft-modified polyacrylamide obtained were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com