Thermal insulation covering agent for steel and molten iron slag accumulation with the function of removing sulfur and phosphorus

A technology of thermal insulation covering agent and slag accumulation, which is applied in the field of new type of slag thermal insulation covering agent with the function of removing sulfur and phosphorus, and can solve problems such as limiting the scope of application.

Active Publication Date: 2016-01-20

新疆世全黄金矿业股份有限公司

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, a small amount of carbon (carbon-containing substances) is added, which limits its application range

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

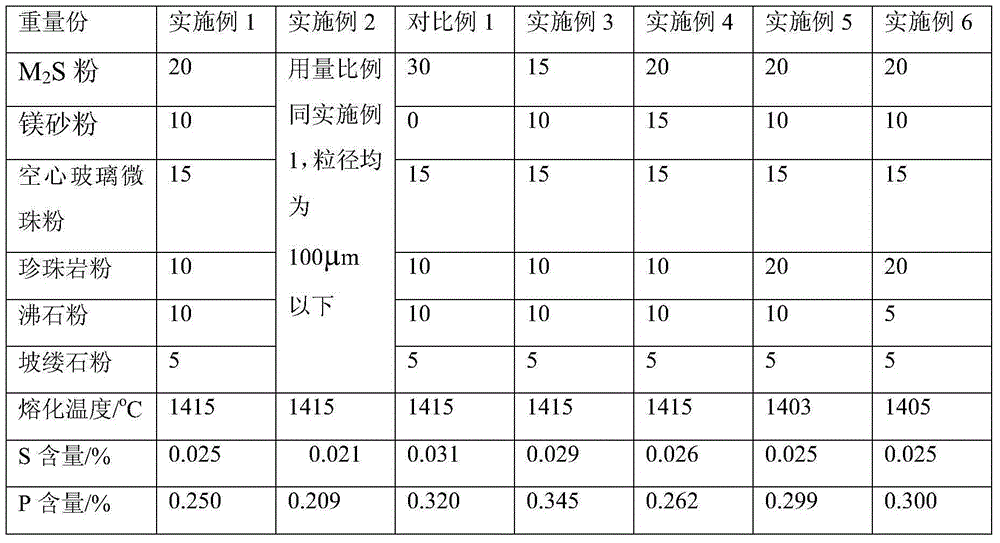

[0035] The particle diameters of the above-mentioned powdery components are all below 100 μm, and other conditions are the same as in Example 1.

Embodiment 3

[0039] 15 servings of M 2 S powder, other conditions are identical with embodiment 1.

Embodiment 4

[0041] 15 parts of magnesia powder, other conditions are identical with embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a molten steel and molten iron slag accretion heat insulation covering agent with a sulphur and phosphorous removal function and a preparation method thereof. The covering agent comprises the following components of, by weight, 10 parts to 20 parts of forsterite powder, 5 parts to 15 parts of magnesia powder, 10 parts to 20 parts of hollow glass bead powder, 10 parts to 20 parts of crushed crude pearlite, 5 parts to 15 parts of zeolite powder and 5 parts to 15 parts of palygorskite powder. By the combined action of the raw materials, the optimum sulphur and phosphorous removal function can be achieved. During covering of steel ladles and molten steel and molten iron in tundishes of steel works, good heat insulation and inclusion absorption of the molten steel and molten iron can be achieved, recarburization of the molten steel is prevented, and sulphur and phosphorous elements in the molten steel and molten iron are absorbed particularly.

Description

technical field [0001] The invention relates to a covering agent for accumulating slag and heat preservation of steel and molten iron in the foundry industry, in particular to a novel slag accumulating heat preservation covering agent with the function of removing sulfur and phosphorus and a preparation method thereof. Background technique [0002] In foundry production, in order to prolong the solidification time of the molten metal in the riser, the covering material covered on the surface of the molten metal in the riser is called a covering agent. There are two kinds of covering agents: thermal insulation covering agent and heating covering agent. [0003] CN102554141A discloses a heat-generating covering agent for steel castings, wherein the weight percentage of each component is: heat-generating agent 5-25%, heat-retaining agent 10-20%, triggering agent 3-8%, wood chips 1%, and the rest Both are slag accumulators, in which the exothermic agent is aluminum powder, alum...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D1/00B22D11/111

Inventor 陈志芳

Owner 新疆世全黄金矿业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com