A high-efficiency bipolar lead-acid battery

A lead-acid battery, bipolar technology, used in lead-acid batteries, lead-acid battery construction, batteries with bipolar electrodes, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

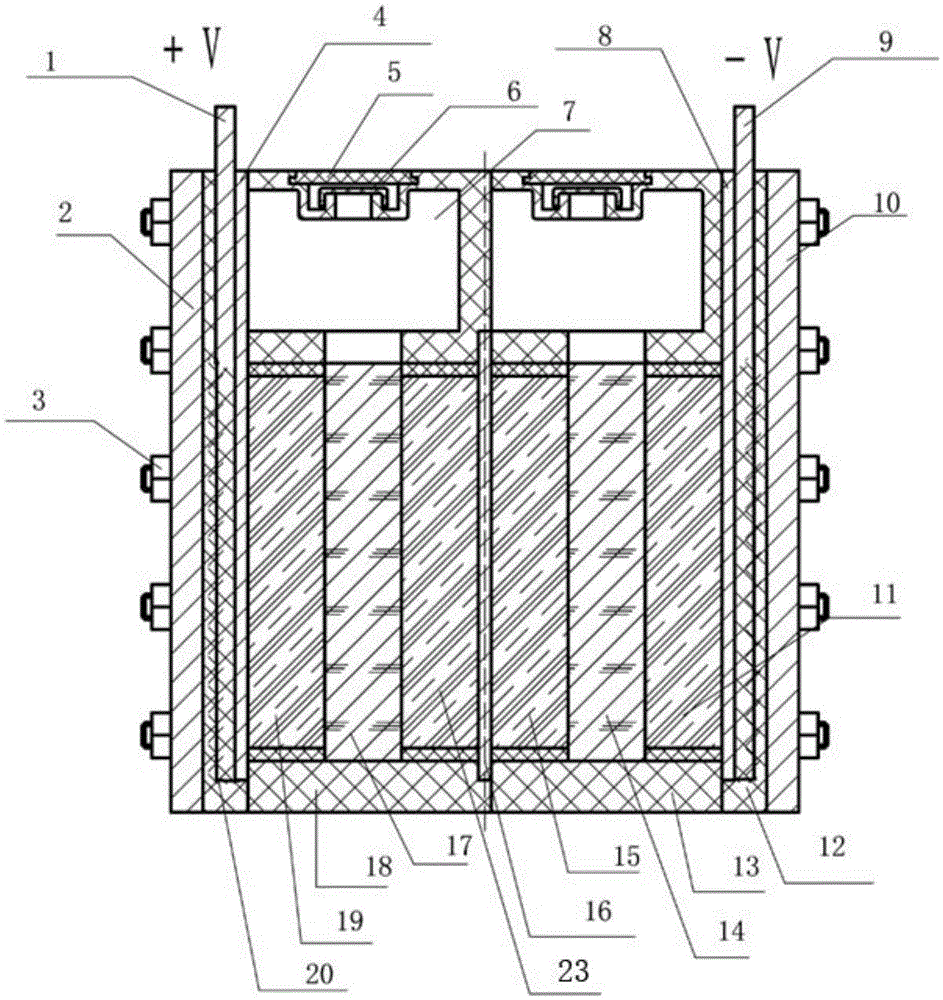

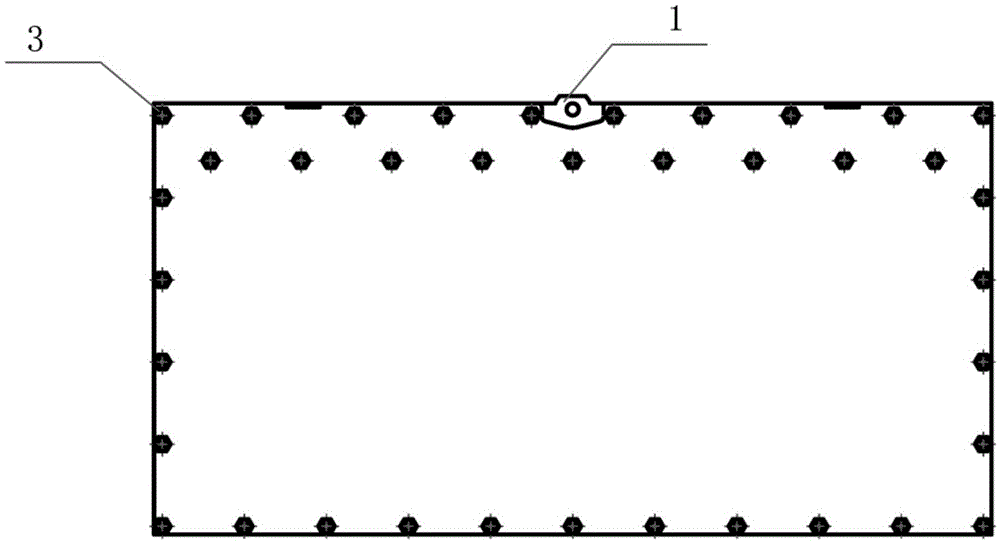

[0024] Such as figure 1 As shown, this embodiment is a high-efficiency bipolar lead-acid storage battery. The storage battery uses a bipolar plate, including a positive terminal electrode, a negative terminal electrode, and a The bipolar plate between the electrodes; the positive terminal electrode and the negative terminal electrode include the electrode copper sheet and the electrode lead sheet, and the electrode copper sheet is soldered on the electrode lead sheet, and the melting point of ordinary solder is close to that of lead, so Conventional soldering materials cannot be used. In this embodiment, the soldering material is lead-tin eutectic material, and the soldering temperature is precisely controlled at about 280 degrees. In order to ensure that the current will not be too large due to the accumulation of electrons at the top, resulting in overheating and melting of the solder joints, which will cause the electrode copper sheet and the electrode lead sheet to be disc...

Embodiment 2

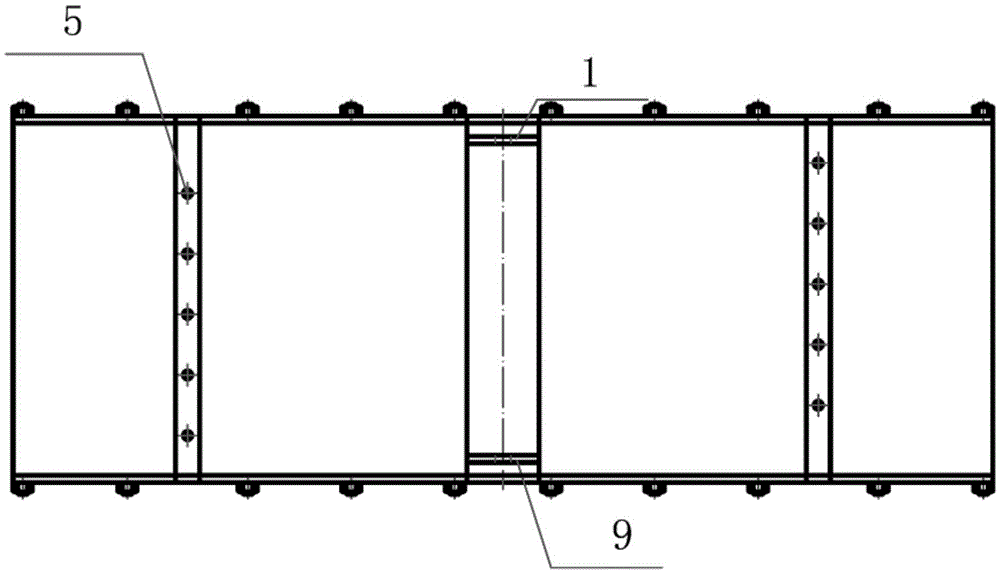

[0030] Such as image 3 As shown, it is a storage battery composed of 10 compartments, which includes a positive electrode, a negative electrode, and 9 bipolar plates arranged between the positive electrode and the negative electrode, wherein the positive line The structure of the electrode and the negative electrode is similar to the first embodiment, and the nine bipolar plates are arranged according to the principle of opposite polarity: the positive electrode is equipped with the negative electrode and the negative electrode is arranged correspondingly, that is, the positive terminal electrode is paired with the first The negative electrode side of 1 bipolar plate, the positive electrode side of the 1st bipolar plate is facing the negative electrode side of the 2nd bipolar plate...and so on until the last bipolar plate One side of the positive electrode of the polar plate is opposite to the negative electrode side of the negative terminal electrode. Each bipolar plate div...

Embodiment 3

[0032] The manufacturing steps of the pole plate grid in the lead-acid battery: firstly adopt common mesh cloth, preferably, the material of this mesh cloth adopts the material of acid resistance, corrosion resistance, is used for the soft mesh cloth, and its mesh cloth often It is woven with very thin wires, and the thin ribs that cannot be injected with plastic are injected around the mesh cloth to form a plastic frame, which is used to shape the mesh cloth to form The plastic grid, and further processes such as pasting, curing and drying on the plastic grid, and the subsequent processes such as pasting, curing and drying are the same as the existing conventional processes. Finally, the plastic plate is bonded to the lead plate. In a bipolar lead-acid battery, the electrodes at both ends are a plastic plate and a lead plate, and the middle plate is a positive plastic plate and a lead plate. Plate and a negative plastic pole plate again, so-called positive pole plastic pole p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com