A method for constructing nanoporous membrane electrodes for direct methanol fuel cells based on sacrificial template method

A methanol fuel cell, nanoporous technology, applied to battery electrodes, structural parts, circuits, etc., can solve the problems that restrict the electrochemical performance, size, and shape of the battery, and it is difficult to realize the controllable construction of the micro-nano structure of the membrane electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

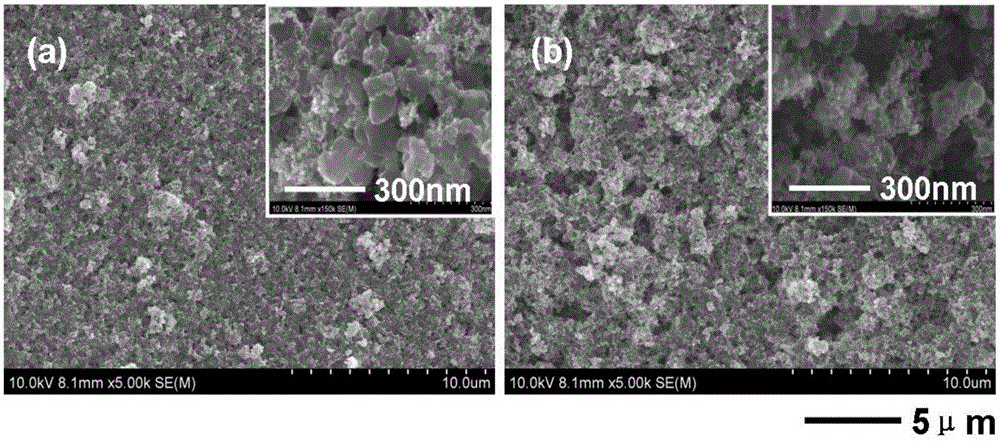

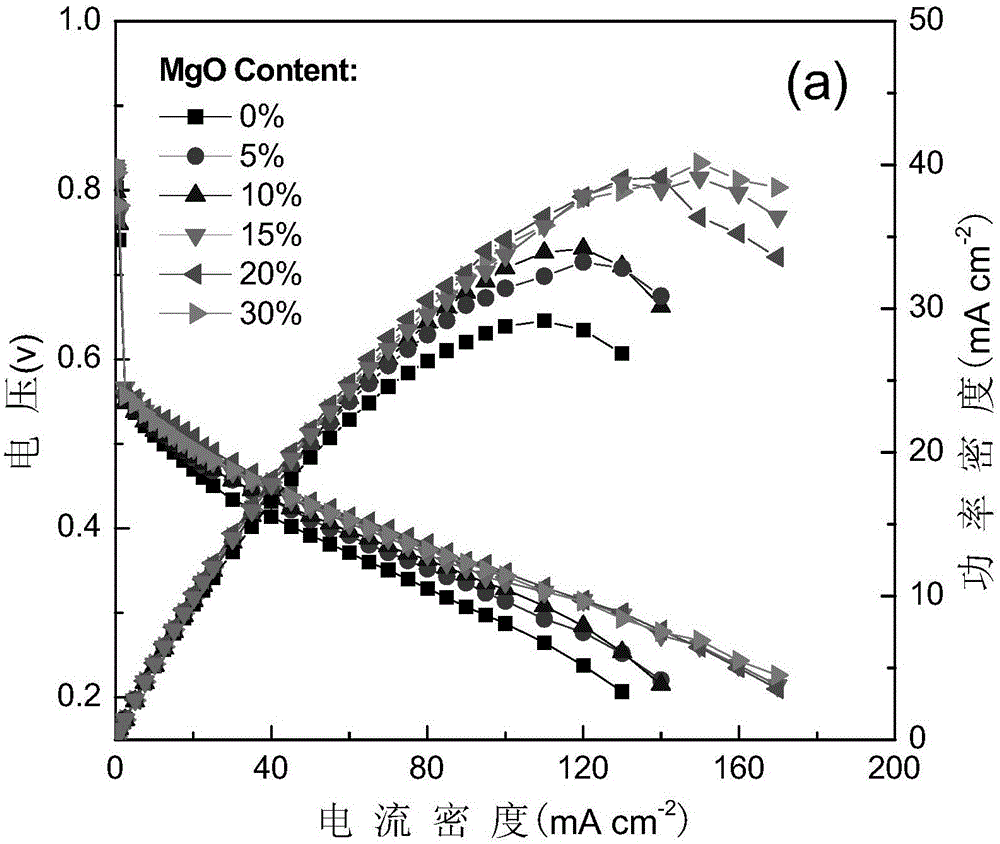

[0060] Example 1—Construction of nanoporous anode catalyst layer of direct methanol fuel cell by using MgO nanoparticles as sacrificial template

[0061] 1. Batch preparation of microporous layer: disperse VulcanXC-72R carbon powder, polytetrafluoroethylene (PTFE) emulsion (density 1.3-1.4, solid content 60wt%) in isopropanol and water (IPA:H 2 O=1:1) in the mixed solution, for the anode carbon powder slurry, the feeding ratio of the dry solid weight in the carbon powder and PTFE emulsion to the isopropanol aqueous solution is 1:0.25:30, and for the cathode carbon powder slurry, the carbon Powder, polytetrafluoroethylene dry weight in polytetrafluoroethylene emulsion, and isopropanol aqueous solution are fed in a ratio of 1:0.5:30, and a uniform viscous slurry is obtained after ultrasonic dispersion. Use an automatic dispenser to evenly spray the toner slurry containing PTFE binder layer by layer onto the cut carbon fiber paper (TorayTGPH-060), and place it in a 350°C muffle f...

Embodiment 2

[0070] Example 2—Construction of nanoporous anode catalyst layer for direct methanol fuel cells by using ZnO nanoparticles as sacrificial templates

[0071] The steps are basically the same as in Example 1, and the MgO nanoparticles are replaced with ZnO nanoparticles, wherein the ZnO addition is 30wt%, and the precious metal loading in the cathode and anode catalyst layers is 4.0mgcm -2 .

[0072] Depend on Figure 5 It can be seen that the maximum power density of the MEA anode catalytic layer can reach 42.3mWcm -2 , is similar to the effect of using MgO, indicating that the method of using metal oxides that are easily soluble in dilute acids as sacrificial templates to construct MEA nanoporous structures has certain universality.

Embodiment 3

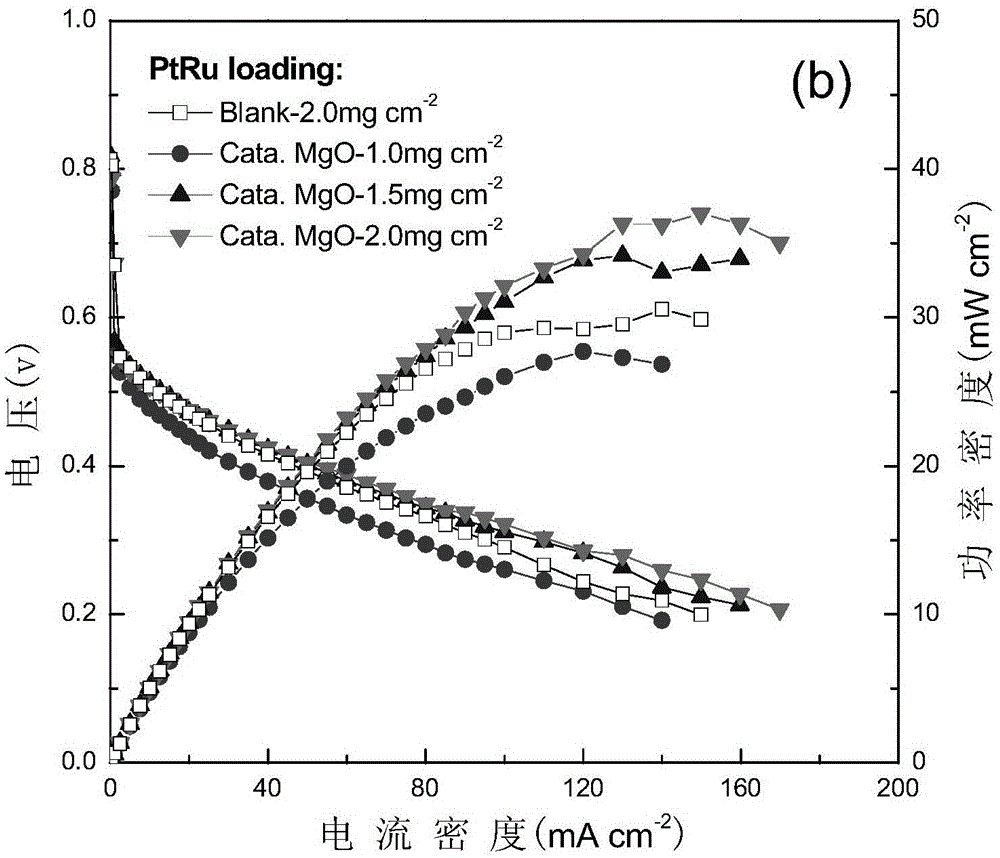

[0073] Example 3 — Constructing a nanoporous anode microporous layer of a direct methanol fuel cell by using MgO nanoparticles as a sacrificial template

[0074] 1. Preparation of microporous layer: basically the same as step 1 of Example 1, in addition, a certain amount of MgO nanopowder was added to the anode carbon powder slurry, and its weight accounted for 30wt% of the total dry weight of the microporous layer slurry.

[0075] 2. Preparation of catalytic layer slurry: basically the same as Step 2 of Example 1, but no MgO or ZnO powder is added during the preparation of the catalyst slurry.

[0076] 3. Prepare a membrane electrode with a nanoporous anode microporous layer according to steps 3-5 of Example 1.

[0077] Depend on Image 6 It can be seen that when the amount of magnesium oxide added to the anode microporous layer is 30wt.%, the PtRu noble metal loading of the anode is 1.0, 1.5, 2.0 mgcm -2 Under these conditions, the maximum power densities of single cells a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com