Biomass superstructure carbon as well as preparation method and application thereof

A biomass and superstructure technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low output, high cost of microporous carbon materials, difficulties in transmission and storage, and achieve expensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

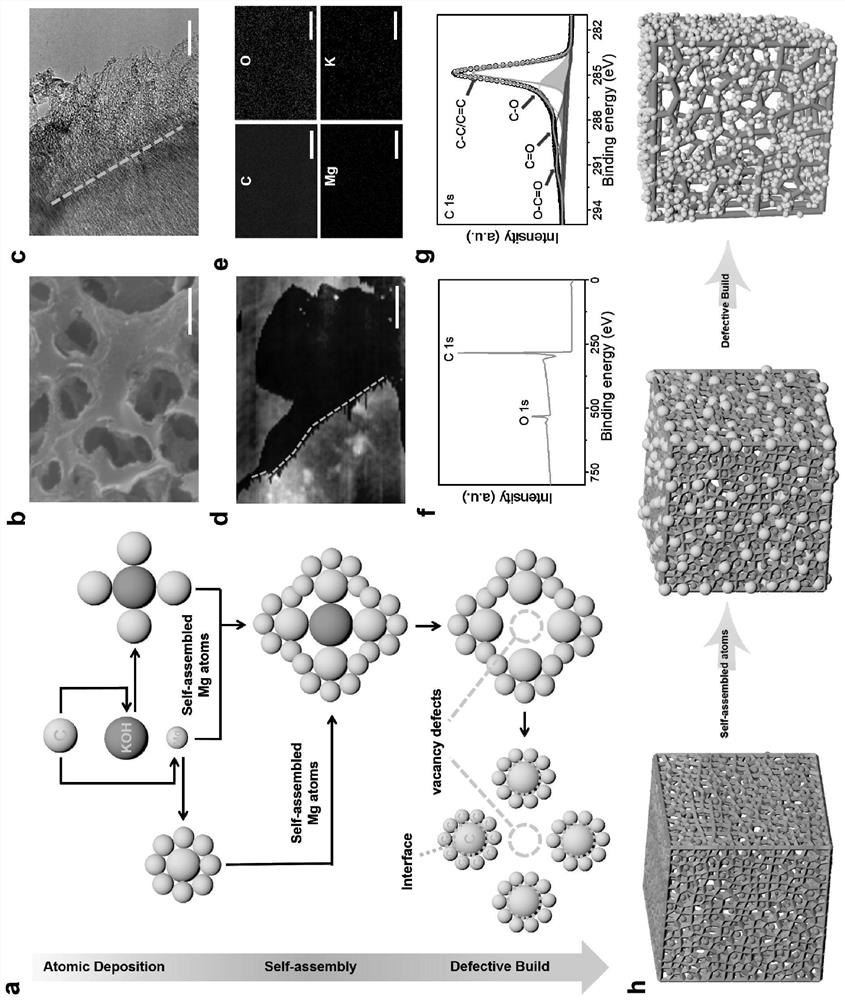

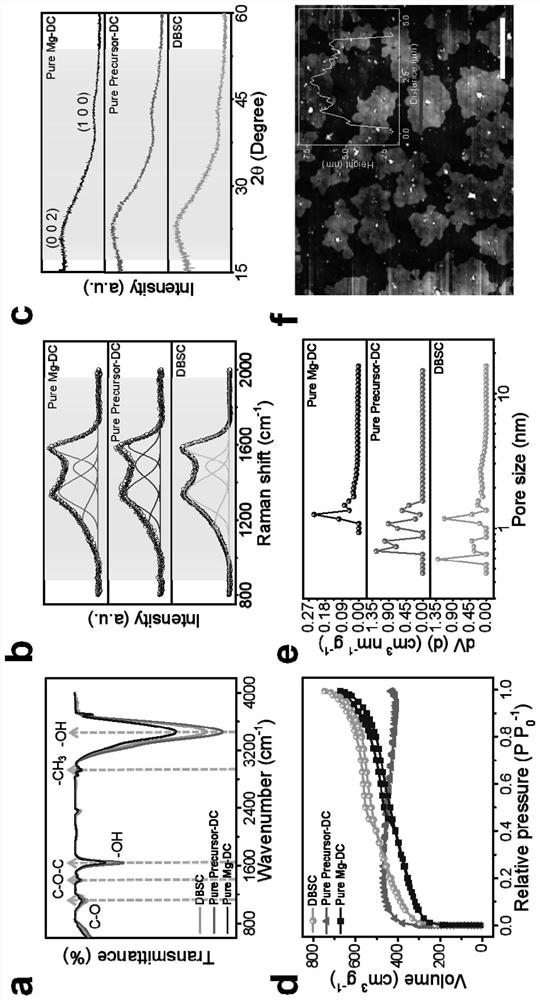

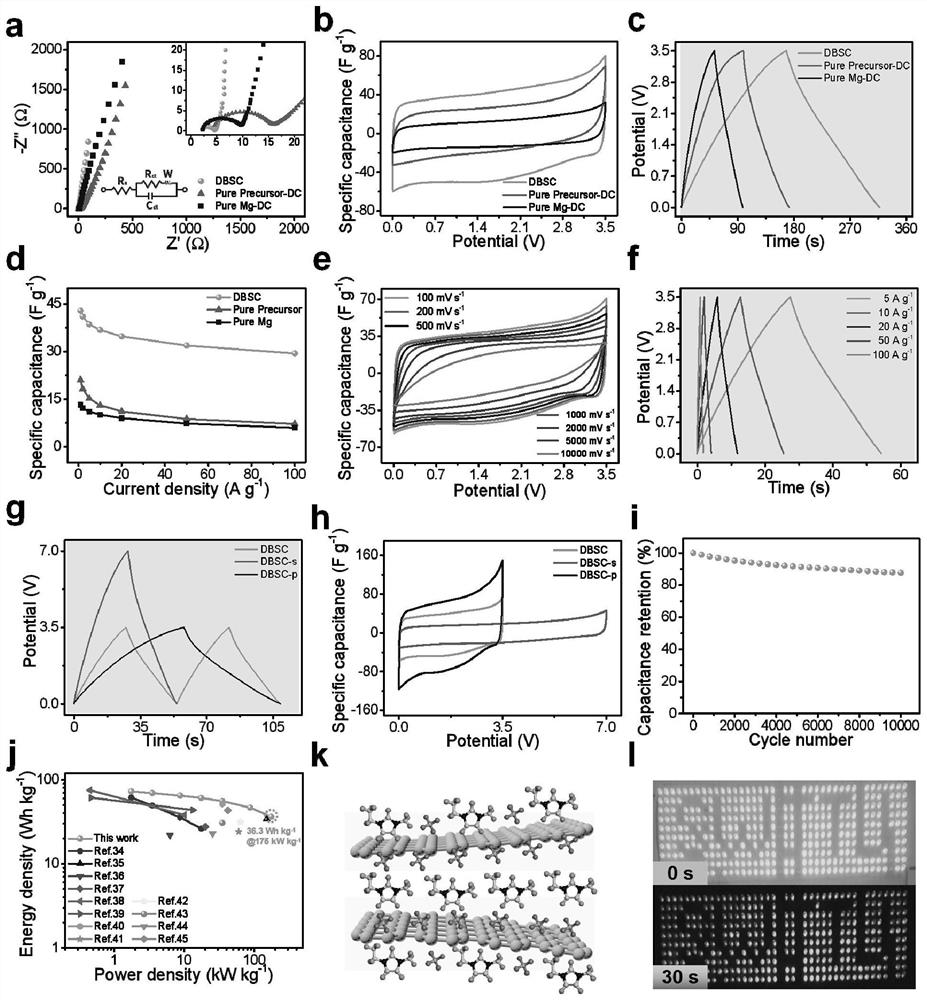

[0031] A preparation method of biomass superstructure carbon, comprising the steps of:

[0032] (1) Biomass precursor preparation: add ramie and 1-6mol / L KOH solution into the reaction lining according to the ratio of 1g to 6mol / L: 30-40mL, and then heat up to 170-190°C, and set the temperature at 170-190°C React for 5-7 hours, cool down after the reaction is over, and then filter with suction to get ramie with KOH molecules pre-embedded, and then dry it to obtain it;

[0033] (2) Preparation of biomass superstructure carbon: Mix the biomass precursor and metal magnesium evenly at a mass ratio of 1 to 6:1, then raise the temperature to 650 to 750°C in a protective gas environment, and then pass the gas flow rate to 15-25sccm of CO 2 React at 650-750°C for 30-90 minutes to obtain it.

Embodiment 1

[0035] A preparation method of biomass superstructure carbon, comprising the steps of:

[0036] (1) Preparation of biomass precursor: add ramie and 3mol / L KOH solution into the reaction lining according to the ratio of material to liquid: 1g: 35mL, and then place it in a hydrothermal reaction kettle and heat it up to 180°C in a blast drying oven , reacted at 180°C for 6 hours, cooled after the reaction was completed, and filtered to obtain ramie with KOH molecules pre-embedded, and then dried at 70°C for 12 hours to obtain the product;

[0037] (2) Biomass superstructure carbon preparation: the biomass precursor and metal magnesium were mixed in a ball mill at a rotation speed of 500r / min for 2h at a mass ratio of 3:1, and then in an argon environment with a gas flow rate of 40sccm Raise the temperature to 700°C, and then feed CO with a flow rate of 20 sccm 2 React at 700°C for 60 minutes to obtain it.

[0038] (3) Immerse the biomass superstructure carbon obtained in step (...

Embodiment 2

[0040] A preparation method of biomass superstructure carbon, comprising the steps of:

[0041] (1) Preparation of biomass precursor: Add ramie and 2mol / L KOH solution into the reaction lining according to the ratio of material to liquid: 1g: 30mL, and then place it in a hydrothermal reaction kettle and heat it up to 170°C in a blast drying oven , reacted at 170°C for 7 hours, cooled after the reaction, and filtered to obtain ramie with pre-embedded KOH molecules, and then dried at 60°C for 14 hours to obtain the product;

[0042](2) Biomass superstructure carbon preparation: the biomass precursor and metal magnesium were mixed in a ball mill at a rotation speed of 400r / min for 2.5h at a mass ratio of 2:1, and then placed in an argon environment with a gas flow rate of 30sccm The temperature was raised to 750°C, and then the gas flow rate was 15 sccm of CO 2 Reaction at 750 ° C for 30 minutes, that is.

[0043] (3) Submerge the biomass superstructure carbon obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com