Low-igniting-voltage miniature semiconductor bridge igniting assembly

A semi-conductor and low-ignition technology, applied in weapon accessories, blasting barrels, fuzes, etc., can solve the problems of poor charge resistance and poor electromagnetic safety, and achieve the effect of reducing ignition energy, high safety current and rapid action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

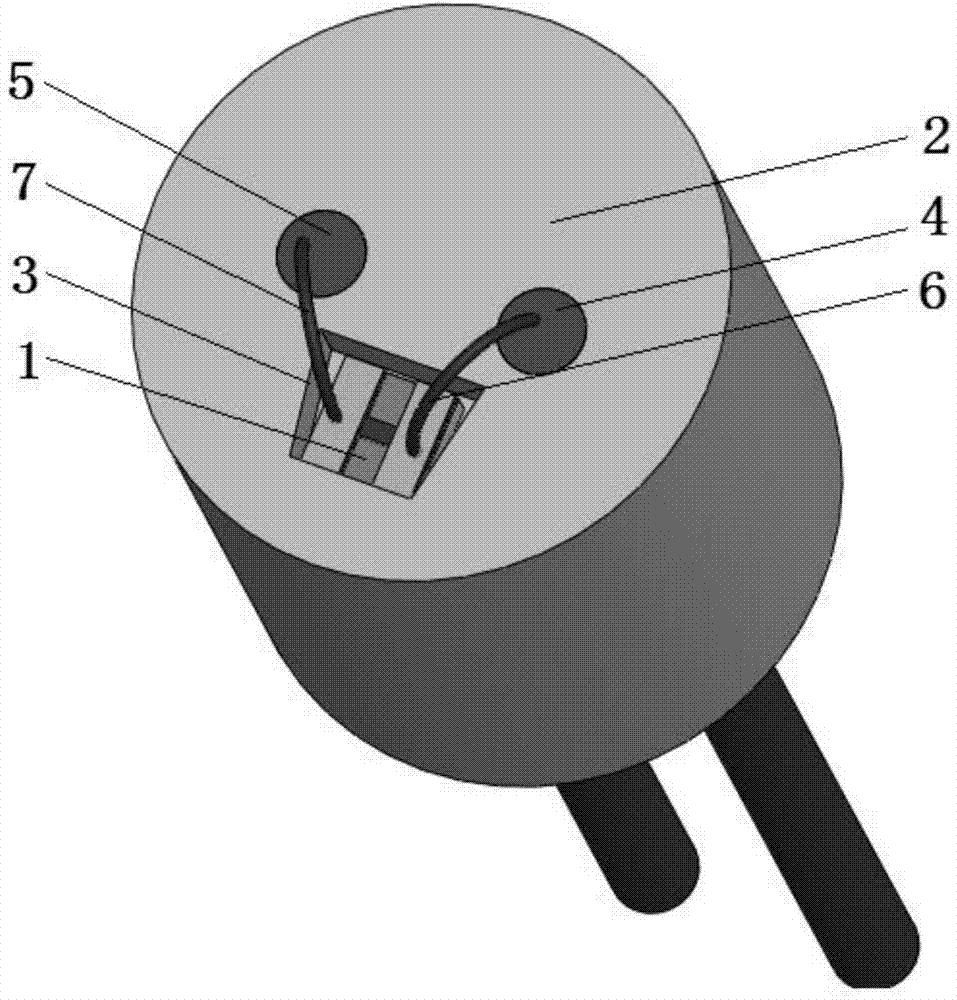

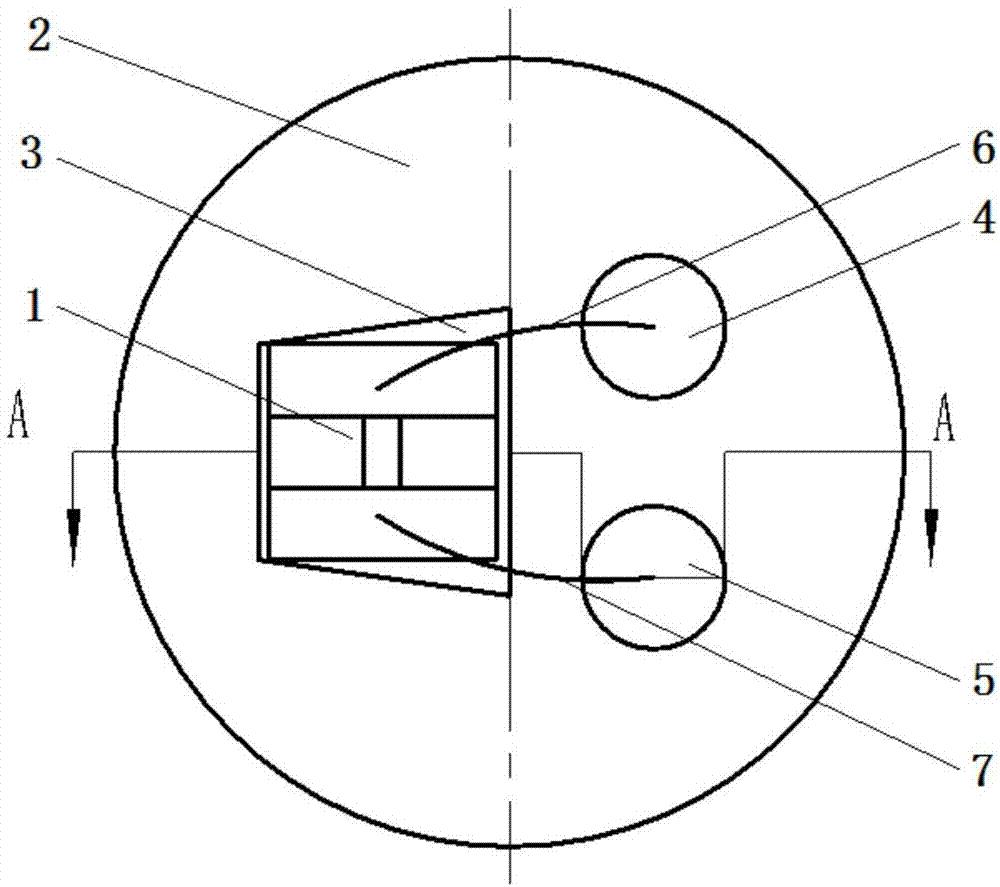

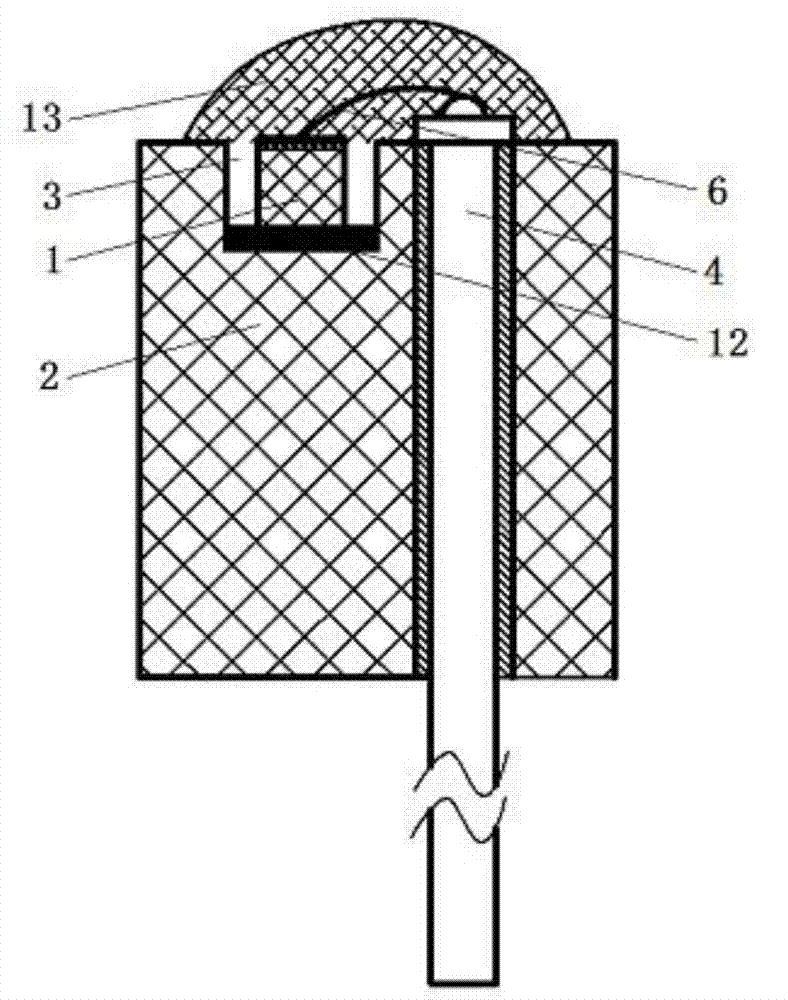

[0023] Embodiment: The substrate of the semiconductor bridge transducer chip is monocrystalline silicon, which is first oxidized into a silicon dioxide layer with a thickness of 0.2 μm on the monocrystalline silicon, and a layer of polycrystalline silicon with a thickness of 2 μm is deposited by vapor deposition, and then doped with P Atoms, the doping concentration is 7.7×1019 / cm3, and then a rectangular pattern is etched through a mask, and finally two metal pads are evaporated with a thickness of 0.2 μm for external circuit connection. The pad material is aluminum or Gold, and then mask the required pattern by photolithography, and obtain a single semiconductor bridge transducer chip by scribing. The side length of the semiconductor bridge transducer chip is 0.5mm, the height is 0.6mm, and the bridge area is 20 μm in length and 20 μm in width. is 50μm, and the resistance is 3.5Ω.

[0024] Adhesive for a rectangular semiconductor bridge transducer chip (1) with a length of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com