Antibacterial hard stainless steel tool and preparation method thereof

A technology of stainless steel and knives, which is applied in the field of antibacterial hard stainless steel knives and its preparation, can solve the problems of affecting the quality of knives, the decline of antibacterial performance, and high production costs, and achieve excellent and durable antibacterial ability, surface hardness and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An antibacterial hard stainless steel knife and a preparation method thereof. Place the stainless steel knife to be treated vertically in a high-energy ion implanter with the blade facing upwards, first perform ion cleaning on the surface of the stainless steel knife to be treated, then perform silver ion implantation, and then perform nitrogen ion implantation to obtain antibacterial hard stainless steel knives .

[0039] The working condition of silver ion implantation described in the present embodiment is: vacuum chamber pressure is 1.0×10 -3~3.0×10 -3 Pa; ion source acceleration voltage is 70-100 KV; silver ion implantation dose is 5.0×10 17 ~1.0×10 19 ions / cm 2 .

[0040] The working condition of the nitrogen ion implantation described in this embodiment is: the vacuum chamber pressure is 1.0×10 -3 ~3.0×10 -3 Pa; ion source acceleration voltage is 80-100KV; nitrogen ion implantation dose is 5.0×10 18 ~1.0×10 19 ions / cm 2 .

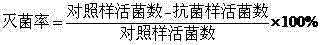

[0041] The antibacte...

Embodiment 2

[0043] An antibacterial hard stainless steel knife and a preparation method thereof. Place the stainless steel knife to be treated vertically in a high-energy ion implanter with the blade facing upwards, first perform ion cleaning on the surface of the stainless steel knife to be treated, then perform silver ion implantation, and then perform nitrogen ion implantation to obtain antibacterial hard stainless steel knives .

[0044] The working condition of silver ion implantation described in the present embodiment is: vacuum chamber pressure is 1.0×10 -3 ~3.0×10 -3 Pa; ion source acceleration voltage is 70~100 KV; silver ion implantation dose is 5.0×10 17 ~1.0×10 19 ions / cm 2 .

[0045] The working condition of the nitrogen ion implantation described in this embodiment is: the vacuum chamber pressure is 1.0×10 -3 ~3.0×10 -3 Pa; ion source acceleration voltage is 60~80 KV; nitrogen ion implantation dose is 5.0×10 17 ~5.0×10 18 ions / cm 2 .

[0046] The antibacterial...

Embodiment 3

[0048] An antibacterial hard stainless steel knife and a preparation method thereof. Place the stainless steel knife to be treated vertically in a high-energy ion implanter with the blade facing upwards, first perform ion cleaning on the surface of the stainless steel knife to be treated, then perform silver ion implantation, and then perform nitrogen ion implantation to obtain antibacterial hard stainless steel knives .

[0049] The working conditions of the cleaning source for ion cleaning described in this embodiment are: filament current 5-15A; arc voltage 20-80V; extraction voltage 1-5 KV; extraction current 20-80mA.

[0050] The working condition of silver ion implantation described in the present embodiment is: vacuum chamber pressure is 1.0×10 -3 ~3.0×10 -3 Pa; ion source acceleration voltage is 70~100 KV; silver ion implantation dose is 5.0×10 17 ~1.0×10 19 ions / cm 2 .

[0051] The working condition of the nitrogen ion implantation described in this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com