PAMAM (polyamidoamine) dendrimer supported Schiff base compound as well as preparation method and application thereof

A technology of polymer loading and alkali compounds, applied in the preparation of imino compounds, chemical instruments and methods, applications, etc., can solve the problems of ineffective reduction of heavy metal content and large amount of adsorbents, and achieve safe use and high adsorption capacity. Large and strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

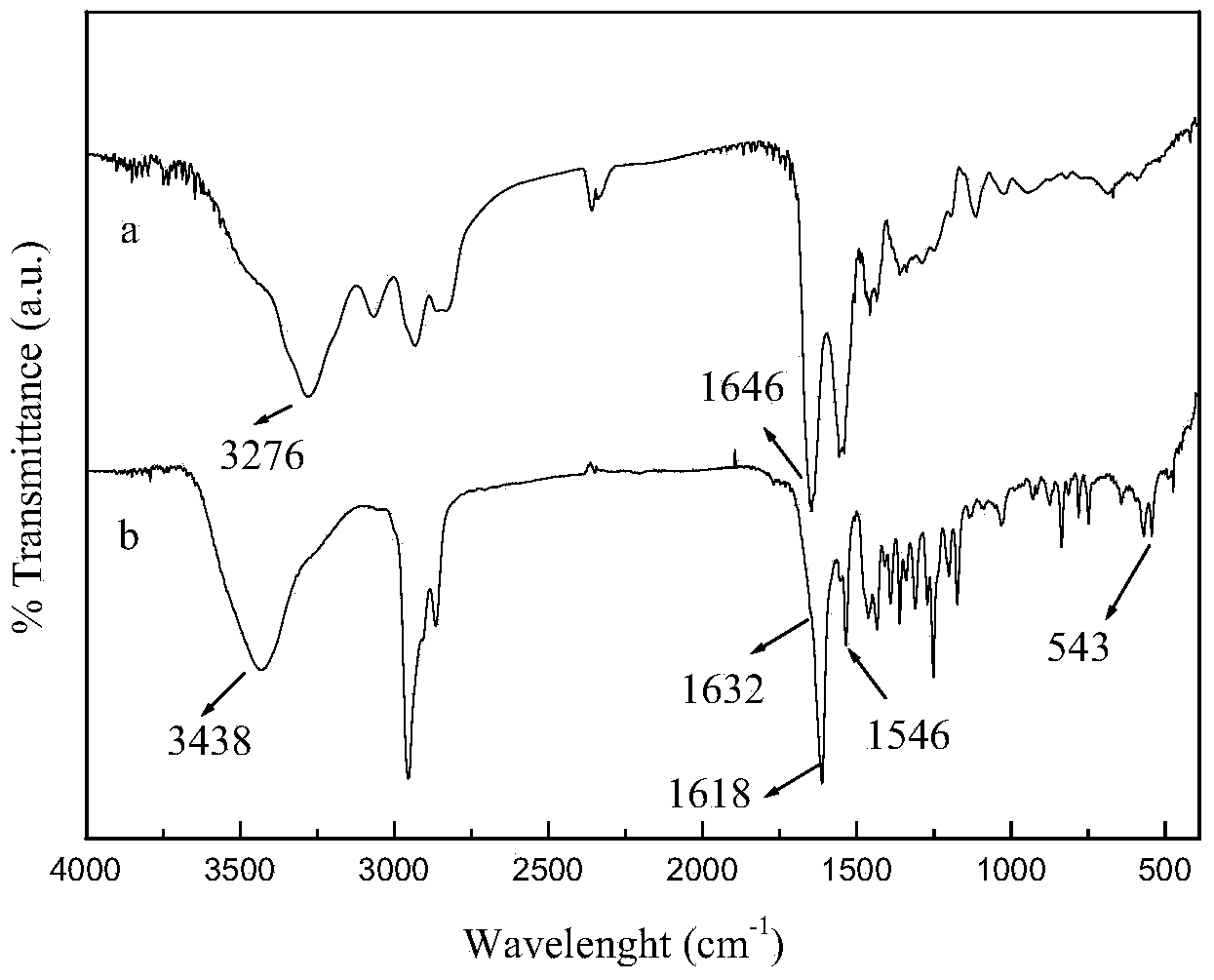

Image

Examples

Embodiment 1

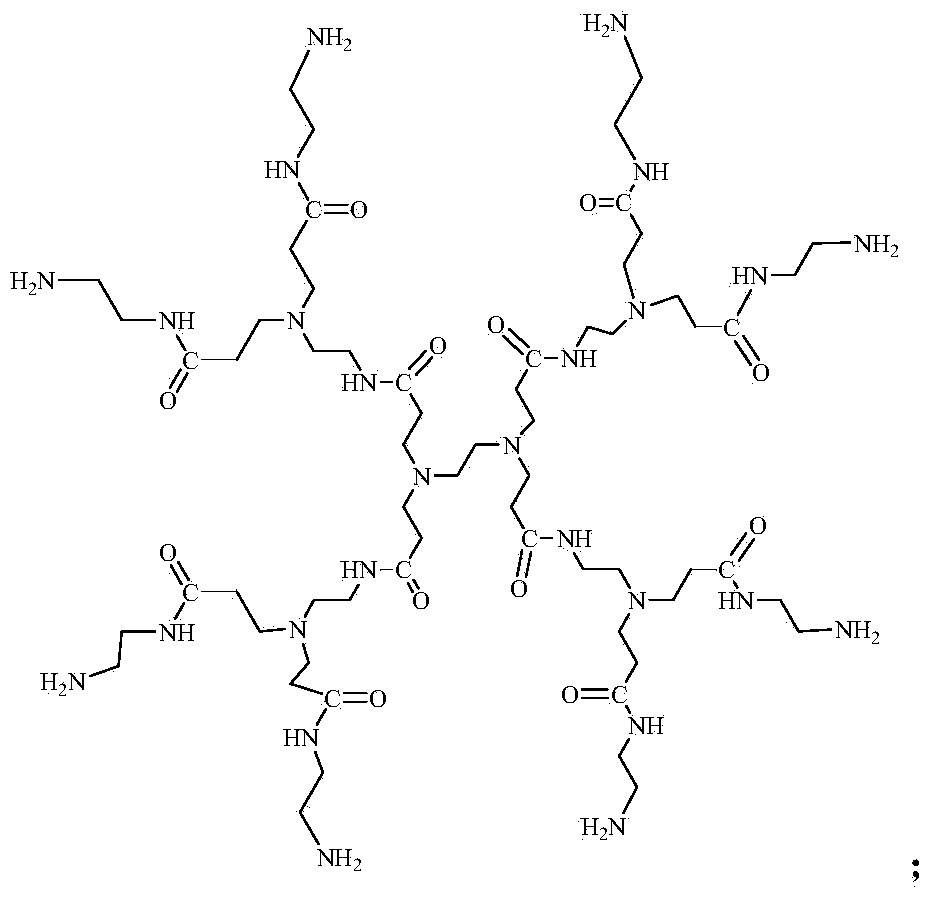

[0049] (1) Synthesis of the first generation (G1.0) polyamide-amine dendrimer carrier

[0050] At 25°C, ethylenediamine (EDA) (1.202g, 20mmol) was used as the nucleus of the macromolecule, and methyl acrylate (MA) (6.887g, 80mmol) was reacted in 50mL methanol solution for 72h, and the solution was heated at 70 Rotary evaporation under reduced pressure at ℃, when the solvent is spin-dried, cool to room temperature, add methanol to the system to dissolve, and then perform rotary evaporation under reduced pressure at 70°C, repeat three times to obtain the product, vacuum-dry at 50°C to obtain The 0.5 generation (G0.5) macromolecule has four ester functional groups at the end of the macromolecule. G0.5 (4.042g, 40mmol of ester group) was dissolved in anhydrous methanol, and then EDA (2.4g, 40mmol) was added dropwise to the system reaction system, and the mixture was reacted at room temperature for 72h, and the solution was Perform reduced-pressure rotary evaporation at 70°C. When...

Embodiment 2

[0059] (1) Synthesis of the second generation (G2.0) polyamide-amine dendrimer carrier

[0060] At 25°C, the synthesized 1.0G dendrimer (2.580g, 20mmol of amine groups) was dissolved in anhydrous methanol, and then, methyl acrylate MA (3.440g, 40mmol) was added dropwise to the system , the mixture was reacted at room temperature for 72 hours. After the reaction, the solution was subjected to reduced-pressure rotary evaporation at 70°C. When the solvent evaporated to dryness, it was cooled to room temperature, methanol was added to the system to dissolve, and the reduced-pressure rotary evaporation was performed again at 70°C. ,repeat three times. Finally, the obtained product was vacuum-dried at 50 °C to obtain a 1.5-generation (G1.5) macromolecule. G1.5 (4.816g, 32mmol of ester group) was dissolved in anhydrous methanol, and then ethylenediamine (EDA) (1.92g, 32mmol) was added dropwise to the system, and the mixture was reacted at room temperature for 72h, After the reactio...

Embodiment 3

[0068] (1) Synthesis of the third generation (G3.0) polyamide-amine dendrimer carrier

[0069] At 25°C, 2.0 g of the synthesized dendrimer (2.856 g, 16 mmol of amine groups) was dissolved in anhydrous methanol, and then methyl acrylate (MA) (2.752 g, 32 mmol) was added dropwise to In the system, the mixture was reacted at room temperature for 72 hours. After the reaction, the solution was subjected to reduced-pressure rotary evaporation at 70°C. When the solvent was evaporated to dryness, cooled to room temperature, methanol was added to the system to dissolve, and the solution was rotated under reduced pressure at 70°C. Evaporate and repeat three times. Finally, the obtained product was vacuum-dried at 50 °C to obtain the 2.5 generation (G2.5) macromolecule. G2.5 (2.804g, 16mmol of ester group) was dissolved in anhydrous methanol, and then ethylenediamine (EDA) (0.96g, 16mmol) was added dropwise to the system, and the mixture was reacted at room temperature for 72h, After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com