NT-BMPkE with bacteria resistance as well as preparation and application thereof

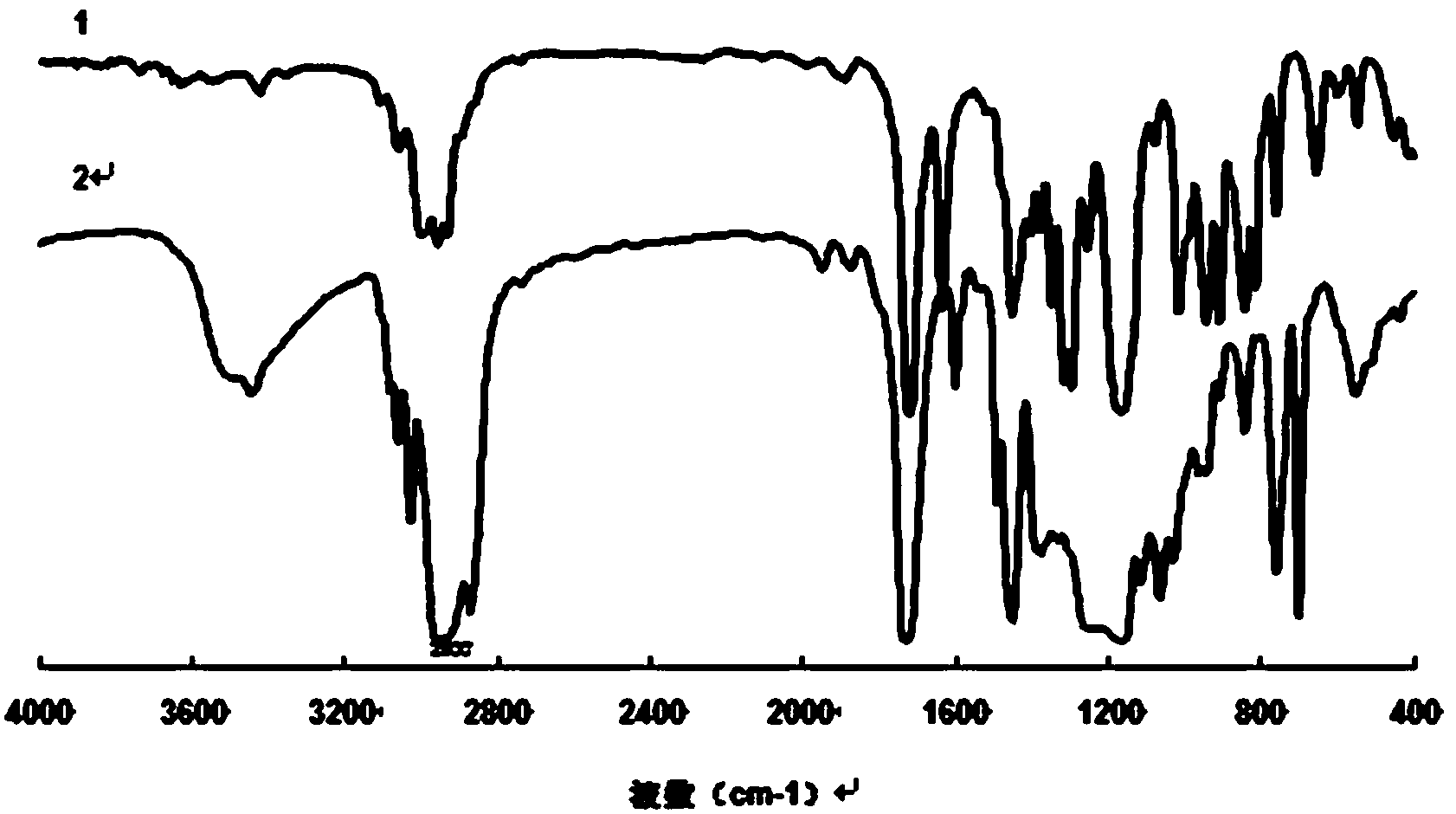

A technology of epoxy styrene acrylate and Pickering emulsion, which is applied in the polymer field and can solve the problems of easy discoloration, poor heat resistance and high cost of antibacterial coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

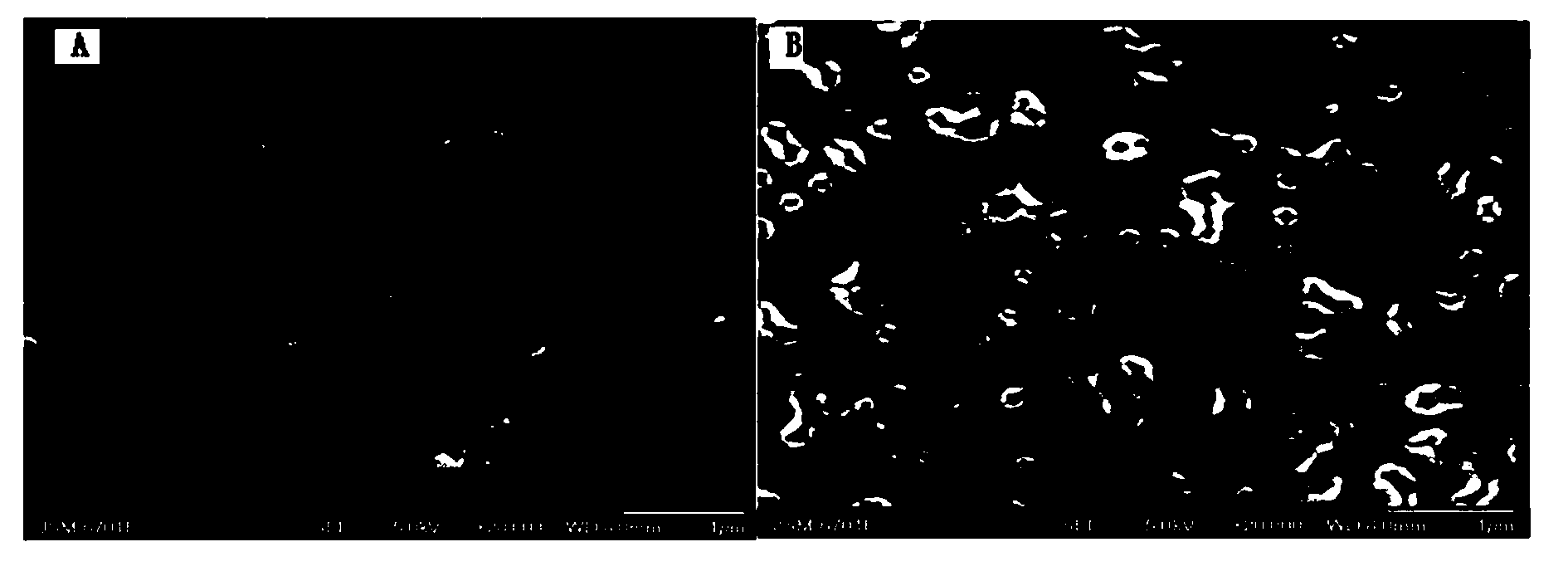

[0050] (1) Preparation of Epoxy-containing Styrene Acrylate Copolymer Pickering Emulsion

[0051] Raw material ratio: by weight

[0052] 10 parts of nano titanium dioxide, 50 parts of methyl methacrylate and butyl acrylate, 50 parts of styrene, 50 parts of glycidyl methacrylate, 10 parts of sodium bicarbonate, 10 parts of potassium persulfate, 50 parts of deionized water.

[0053] Preparation process: Add nano-titanium dioxide and deionized water into the dispersing cup, adjust the pH value of the solution to 1 with dilute HCl, disperse with a high-speed disperser, then move to the reactor, raise the temperature to 60°C, and dissolve the methyl Methyl acrylate, butyl acrylate, styrene, glycidyl methacrylate mixed monomers, and potassium persulfate solution were added dropwise to the reactor within 5 hours. After the dropwise addition, continue to stir and react for 4 hours. After the reaction is complete, a blue-phase white Pickering emulsion is obtained; filter through a 300...

Embodiment 2

[0059] (1) Preparation of Titanium Dioxide Stabilized Acrylate Copolymer Pickering Emulsion

[0060] Raw material ratio: by weight

[0061] 1 part of nano titanium dioxide, 1 part of methyl methacrylate, 10 parts of butyl acrylate, 5 parts of styrene, 10 parts of glycidyl methacrylate, 1 part of sodium bicarbonate, 1 part of potassium persulfate, 1 part of deionized water .

[0062] Preparation process: Add nano-titanium dioxide and deionized water into the dispersion cup, adjust the pH value of the solution to 8 with dilute NaOH, disperse with a high-speed disperser, then move it to the reactor, raise the temperature to 60°C, and dissolve the methyl Methyl acrylate, butyl acrylate, styrene, glycidyl methacrylate mixed monomer, and potassium persulfate initiator solution were added dropwise to the reactor within 4.5 hours. After the dropwise addition, continue to stir and react for 0.5 hours. After the reaction is complete, a blue-phase white Pickering emulsion is obtained, ...

Embodiment 3

[0068] (1) Preparation of epoxy-containing styrene acrylate copolymer Pickering emulsion stabilized by nano-titanium dioxide

[0069] Raw material ratio: by weight

[0070] 5 parts of nano titanium dioxide, 25 parts of methyl methacrylate, 25 parts of butyl methacrylate, 25 parts of styrene, 25 parts of glycidyl methacrylate, 5 parts of sodium bicarbonate, 5 parts of potassium persulfate, deionized water 5 servings.

[0071] Preparation process: Add nano-titanium dioxide and deionized water into the dispersion cup, adjust the pH value of the solution to 3 with dilute HCl, disperse with a high-speed disperser, then move to the reactor, raise the temperature to 85°C, and dissolve the methyl Methyl acrylate, butyl methacrylate, glycidyl methacrylate, styrene mixed monomer, and potassium persulfate initiator solution were added dropwise to the reactor within 4 hours. After the dropwise addition, continue to stir and react. After the reaction is complete, the blue-phase white Pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com