Method for simultaneously extracting chicoric acid, mono-caftaric acid, 3,5-dicaffeoylquinic acid and chlorogenic acid from pterocypsela indica as raw material

A technology of caffeoyl tartaric acid and caffeoyl quinic acid, which is applied in the field of chlorogenic acid, can solve problems such as limited root production, and achieve the effect of reducing raw material costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

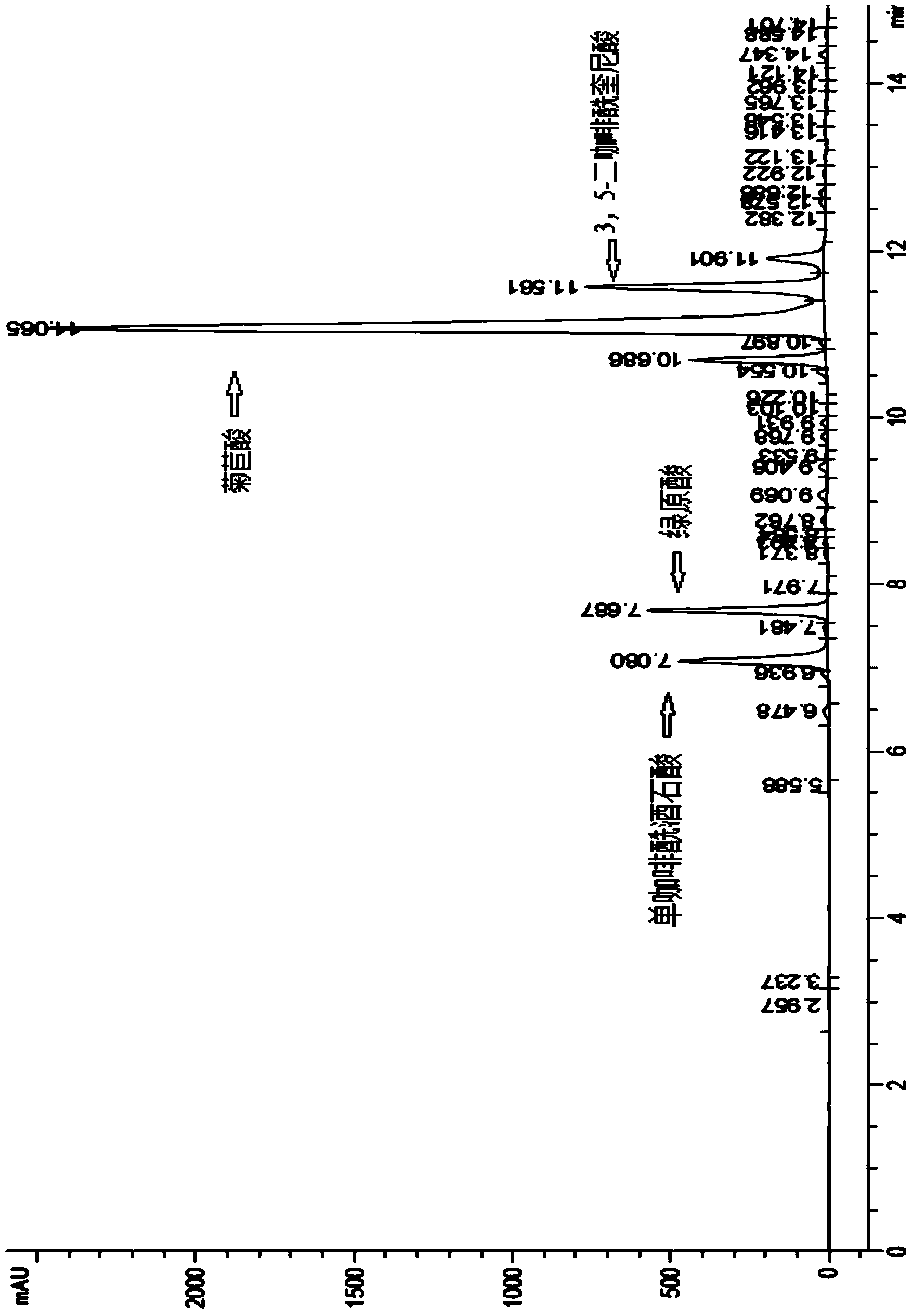

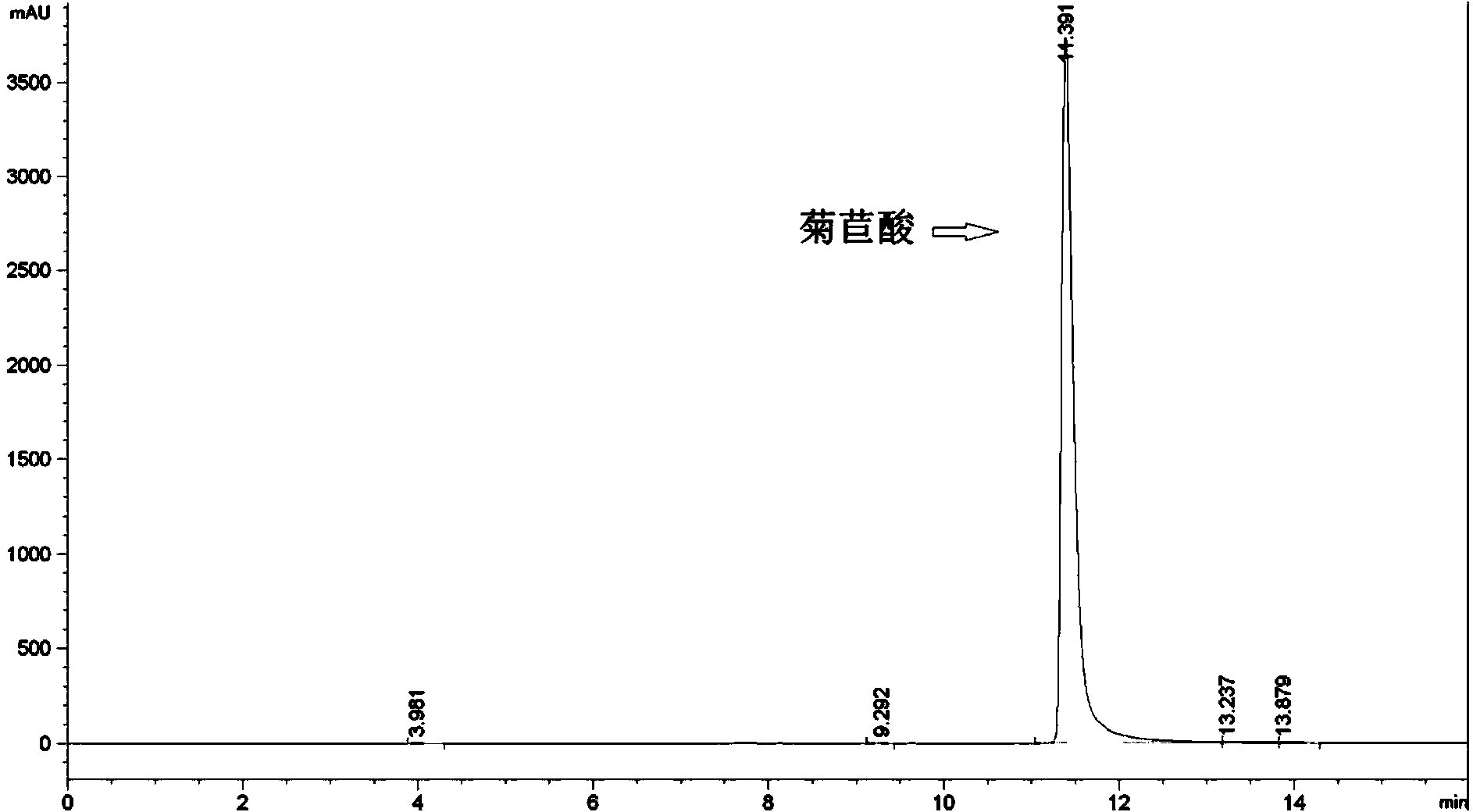

[0040] Take 1000g of the whole plant of Ptera multilobata and add 90% acetone according to the solid-to-liquid ratio of 1:30, and extract at 60°C for 2 hours (see HPLC analysis of the extract). figure 1 ) extract is concentrated and then extracted with n-butanol to obtain an extract containing chlorogenic acid and 3,5-dicaffeoylquinic acid and a raffinate containing cichoric acid and monocaffeoyltartaric acid;

[0041] The extract was separated and refined by conventional adsorption with D101 macroporous resin, and 90% of chlorogenic acid and 3,5-dicaffeoylquinic acid were obtained respectively.

[0042] The raffinate was separated and purified by conventional adsorption with XAD-2 resin to obtain cichoric acid and monocaffeoyl tartaric acid with a content of 90%.

Embodiment 2

[0044] Same as in Example 1, replace the whole plant of Ptera multilobata with the root of Ptera multilobata, add 60% methanol at a solid-to-liquid ratio of 1:100, extract at 90°C for 1.0 h, concentrate the extract with acetone Triol extraction, the extract is separated and refined by conventional adsorption with D301 macroporous resin, and 92% of chlorogenic acid and 3,5-dicaffeoylquinic acid are obtained respectively.

[0045] The raffinate was separated and refined by conventional adsorption with X-5 resin to obtain cichoric acid and monocaffeoyl tartaric acid with a content of 91%.

Embodiment 3

[0047] Same as in Example 1, the whole herb of Sachinacea multilobata was replaced with the leaves of Sachinacea multilobata. Add 70% ethanol at a solid-to-liquid ratio of 1:60, and extract at 60°C for 1 hour. The extract is concentrated and then extracted with isopropanol. After the extract is separated and refined by conventional adsorption with HPD100 resin, 89% of chlorogenic acid and 3,5-dicaffeoylquinic acid are obtained respectively.

[0048] The raffinate was separated and refined by conventional adsorption with HPD300 resin to obtain cichoric acid and monocaffeoyl tartaric acid with a content of 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com