Preparation method of tin-doped titanium dioxide

A titanium dioxide and tin doping technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor product dispersion, achieve the effects of improving catalytic activity, increasing lattice defect density, and increasing oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

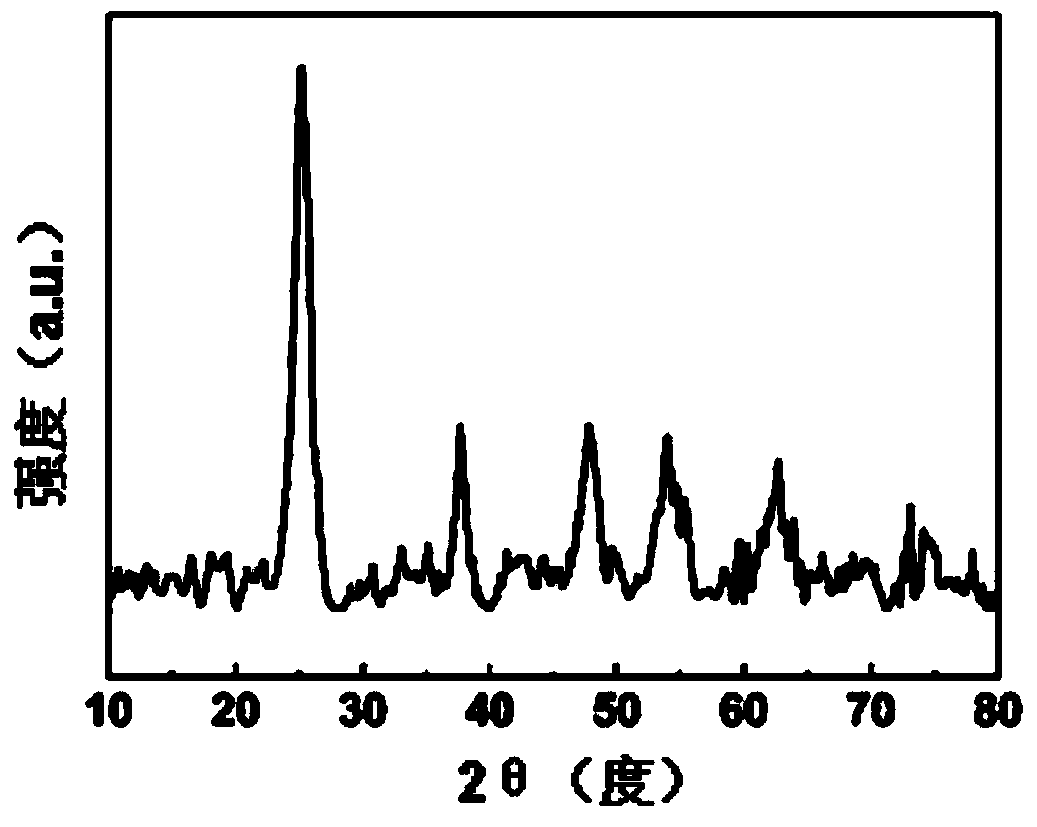

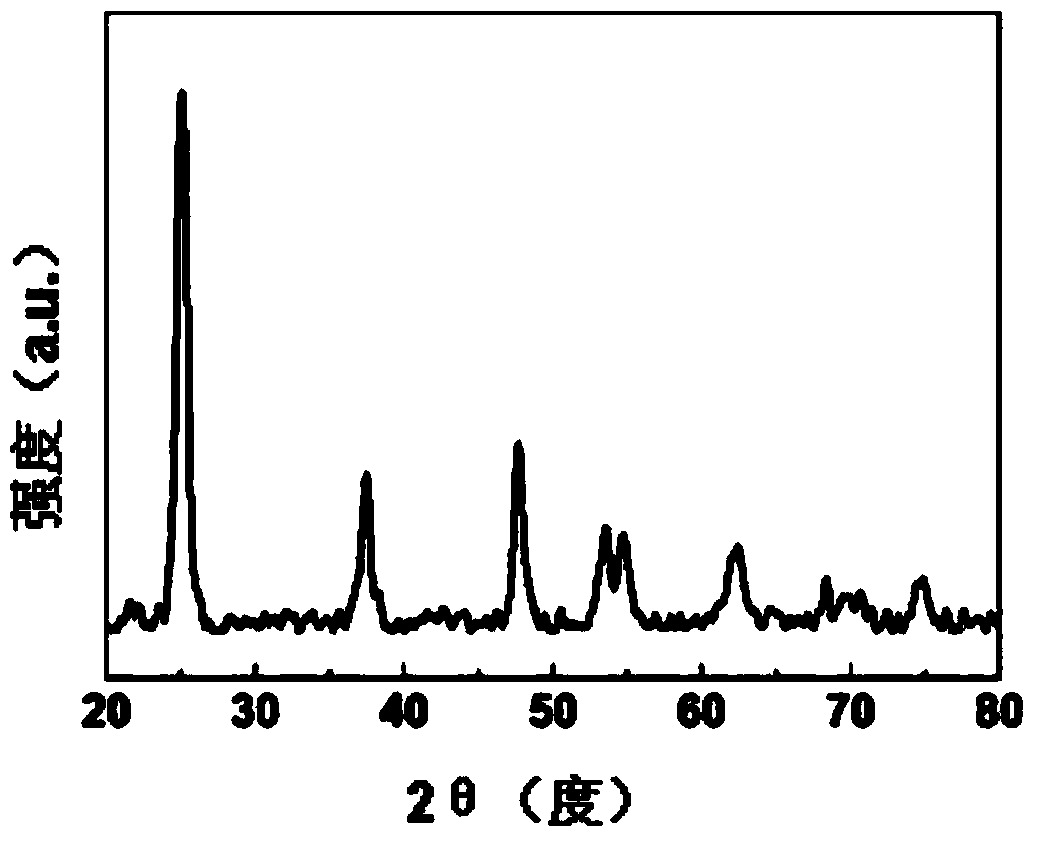

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of tin-doped titanium dioxide in this embodiment is as follows:

[0018] 1. Add butyl phthalate and crystalline tin tetrachloride to 4mL of absolute ethanol at a molar ratio of 8-18:2, stir for 10 minutes, add 35mL of ethylene glycol and stir for 10 minutes, then add 1mL of concentrated hydrochloric acid in sequence and 1mL deionized water, stirred for 10 minutes, added 0.2-0.8g polyvinylpyrrolidone, stirred for 12-48 hours, and a stable and transparent yellow sol was obtained;

[0019] 2. Transfer the yellow sol obtained in step 1 to a polytetrafluoroethylene-lined stainless steel reactor, react for 24 hours at 160-180°C, cool to room temperature naturally, wash with absolute ethanol and distilled water for 6-8 Once again, filter with a 0.22 μm microporous membrane to collect the white precipitate;

[0020] 3. Dry the white precipitate at 60-80° C. for 3-8 hours, grind it, and package it to obtain tin-doped titanium diox...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of butyl phthalate to crystalline tin tetrachloride in step 1 is 8:2. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the molar ratio of butyl phthalate to crystalline tin tetrachloride in step 1 is 9:1. Others are different from the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com