Preparation method of optical clear electro-driven shape memory polymer film

A memory polymer and optically transparent technology, which is applied in the field of preparation of shape memory polymer films, can solve the problems of narrow application range of shape memory polyimide and low light transmittance of shape memory polyimide, so as to reduce energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific Embodiment 1: In this embodiment, the preparation method of the optically transparent electrically driven shape memory polymer film is carried out according to the following steps:

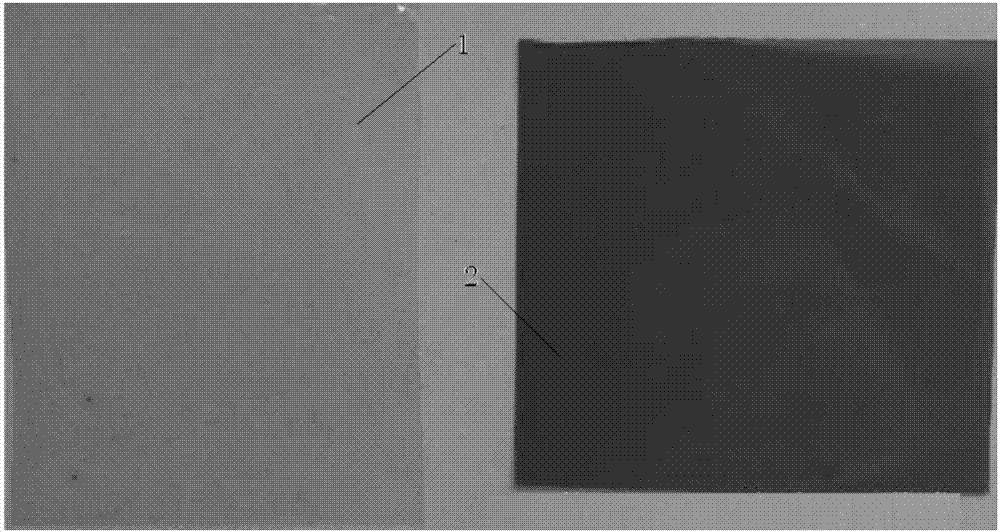

[0037] 1. Drop-coating the transparent conductive coating solution on the support substrate, and sintering at 80-100°C for 10-60 minutes to obtain a support substrate with a transparent conductive coating;

[0038] The sheet resistance of the transparent conductive coating is 1 to 50Ω / sq;

[0039] 2. Coating the precursor solution of shape memory polyimide on the upper surface of the transparent conductive coating, and then placing the support substrate in a vacuum drying oven for constant temperature treatment;

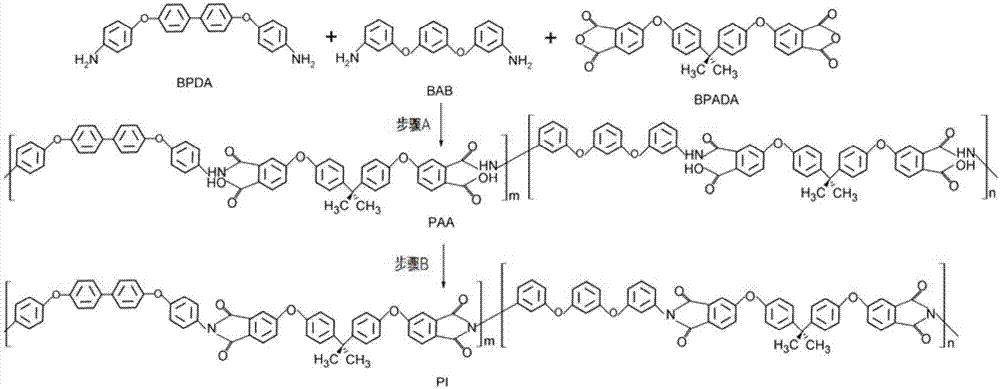

[0040] The preparation method of the precursor solution of the shape memory polyimide is carried out according to the following steps: 1,3-bis(3-aminophenoxy)benzene and 4,4'-bis(4-aminophenoxy) Add biphenyl to the aprotic polar solvent, stir for 20-30min under the condi...

specific Embodiment approach 2

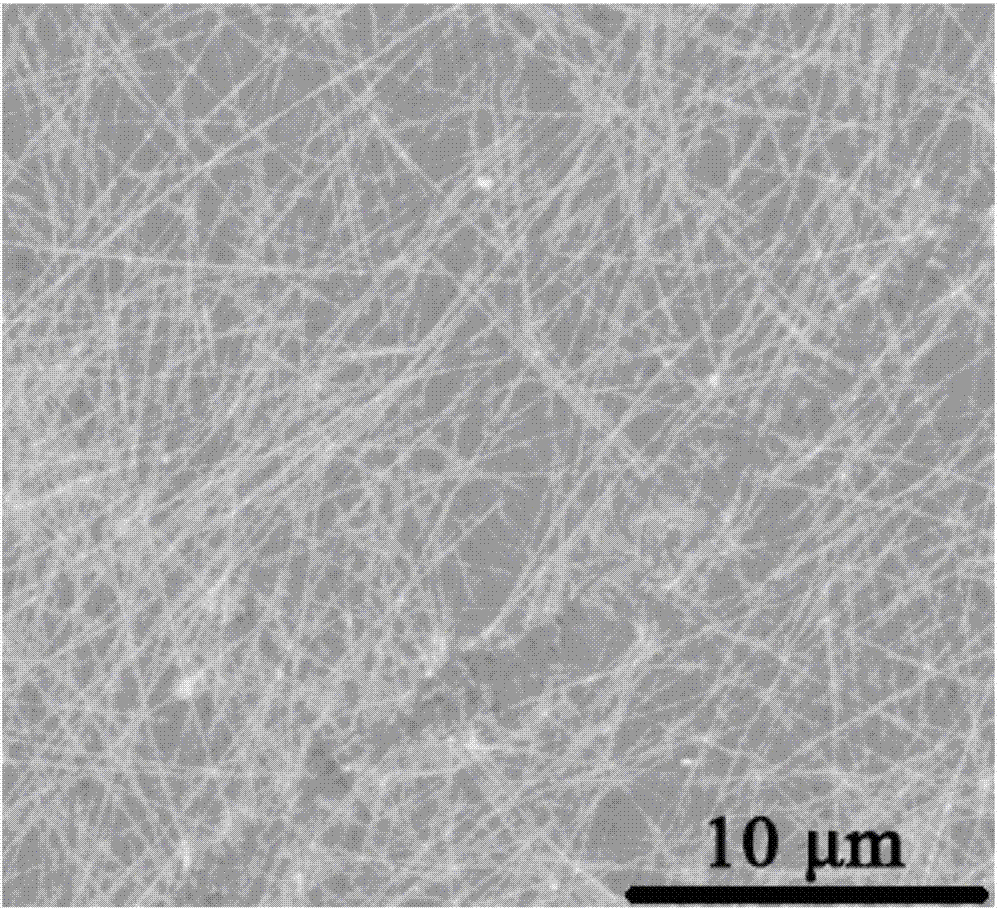

[0052] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the transparent conductive coating solution described in step 1 is a mixture of one or more of silver nanowire conductive solutions, carbon nanotube conductive solutions, and transparent conductive inks. liquid. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0053] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the supporting substrate in step 1 is glass or polyethylene terephthalate. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com