Anti-multipacting nickel-based composite coating and coating method thereof

A composite coating, nickel-based technology, used in coatings, chemical instruments and methods, metal material coating processes, etc., can solve problems such as maintenance, production shutdown, economic losses, etc., to improve anti-collision ability, reduce production costs, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

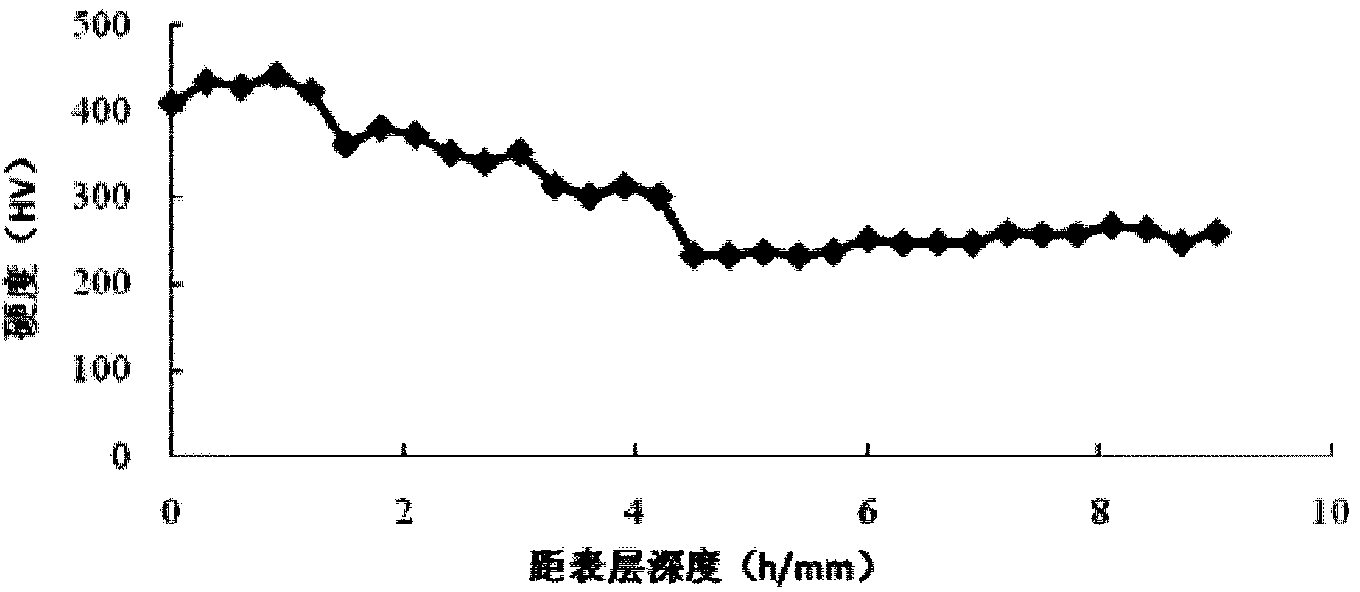

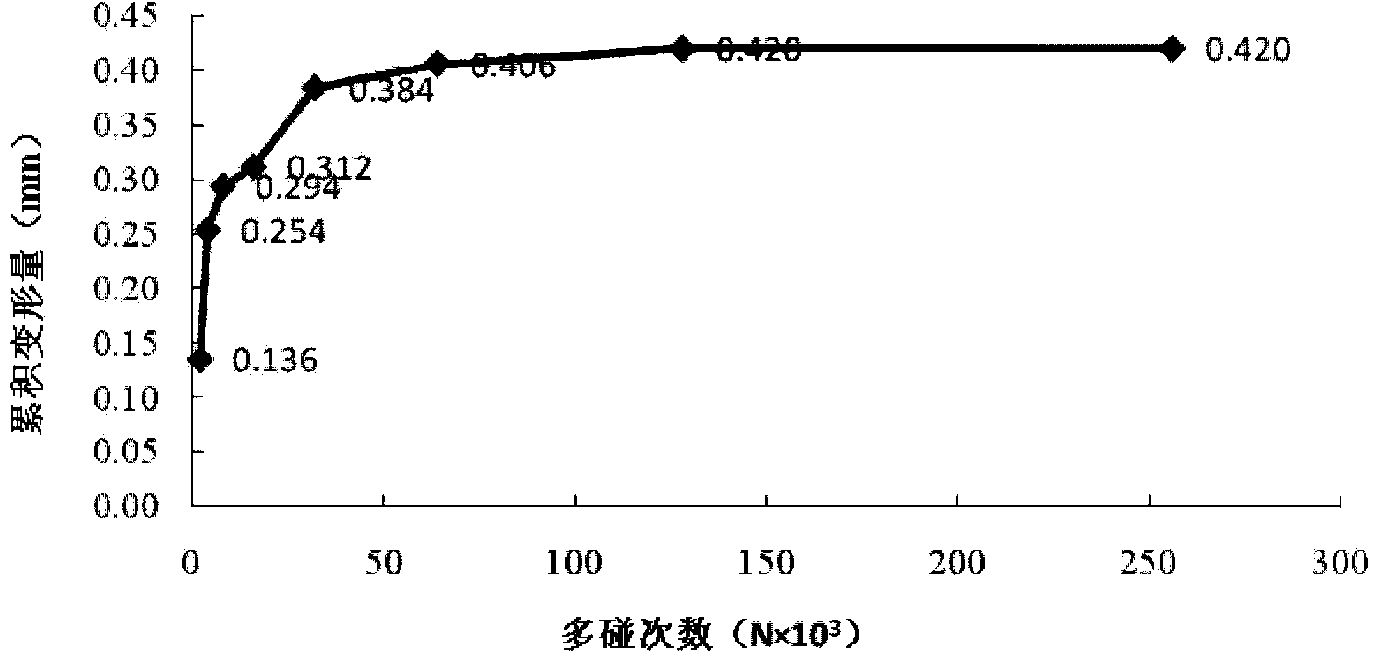

[0018] In order to improve its multi-collision resistance performance, a gradually distributed coating is used on the 0Cr18Ni9 substrate. The weight percentages of Ni in the first, second, third and fourth subcoats are 10%, 22.227%, 37.304% and 44.454%. That is, the Ni content of the fourth layer on the surface of the exponential distribution gradient coating of the specimen is 44.454%, and the height of each layer is controlled to be about 1.5mm. The method of laser cladding is carried out. When the rectangular spot size is 10mm×1mm, the scanning speed V = 5mm / s, and the laser power is 3.5KW-4.5KW, the top surface of the sample is ground after cladding, and the cladding is repeated. Finally, the gradient coating sample was cut into 10mm×5mm×45mm multi-impact specimens. The coating is then subjected to a multi-touch test on a fatigue testing machine. The multi-touch experiment was carried out on the self-made multi-touch fatigue testing machine, the XTL-1 stereo microscope, ...

Embodiment 2

[0021] In order to improve its multi-collision resistance performance, a gradually distributed coating is used on the 0Cr18Ni9 substrate. The weight percentages of Ni in the first, second, third and fourth subcoats are 11%, 25.44%, 37.304% and 42.98%. Control the height of each layer to about 1.5mm. The method of laser cladding is carried out. When the rectangular spot size is 10mm×1mm, the scanning speed V = 5mm / s, and the laser power is 3.5KW-4.5KW, the top surface of the sample is ground after cladding, and the cladding is repeated. Finally, the gradient coating sample was cut into 10mm×5mm×45mm multi-impact specimens. The coating is then subjected to a multi-touch test on a fatigue testing machine. The multi-touch experiment was carried out on the self-made multi-touch fatigue testing machine, the XTL-1 stereo microscope, the JX68302-00 tool microscope were used to observe the microstructure of the sample, and the HXD-1000B digital microhardness tester was used to measur...

Embodiment 3

[0023] In order to improve its multi-collision resistance performance, a gradually distributed coating is used on the 0Cr18Ni9 substrate. The weight percentages of Ni in the first, second, third and fourth subcoats are 10%, 23.69%, 36.92% and 42.98%. Control the height of each layer to about 1.5mm. The method of laser cladding is carried out. When the rectangular spot size is 10mm×1mm, the scanning speed V = 5mm / s, and the laser power is 3.5KW-4.5KW, the top surface of the sample is ground after cladding, and the cladding is repeated. Finally, the gradient coating sample was cut into 10mm×5mm×45mm multi-impact specimens. The coating is then subjected to a multi-touch test on a fatigue testing machine. The multi-touch experiment was carried out on the self-made multi-touch fatigue testing machine, the XTL-1 stereo microscope, the JX68302-00 tool microscope were used to observe the microstructure of the sample, and the HXD-1000B digital microhardness tester was used to measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com