Manufacturing method of environment-friendly, energy-saving, fire-proof and anti-theft door sheet

An anti-theft door panel and production method technology, applied in the direction of manufacturing tools, wood processing utensils, etc., can solve the problems of poor heat preservation, increased hazard, fast carbonization speed, etc., and achieve the effect of being conducive to popularization and application, wide range of uses and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An environment-friendly, energy-saving, fire-proof and anti-theft door panel manufacturing method is characterized in that it comprises the following steps:

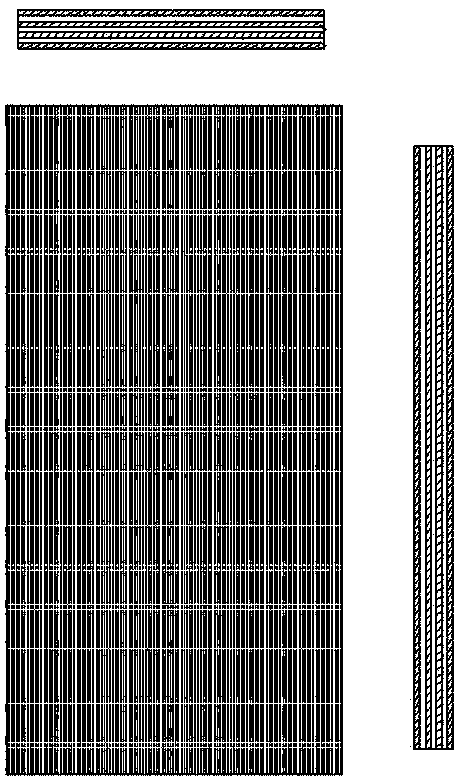

[0042] ①. Slicing or rotary cutting the logs into veneers with a thickness of 1.8mm to 2.0mm;

[0043] ②. Classify the veneers into three grades of boards according to their quality and do flame retardant treatment;

[0044] ③. Put the veneer after flame retardant treatment into a vacuum dryer, and dry the veneer to a moisture content of less than 8%;

[0045] ④. Put together and repair the dried veneers, and evenly apply glue on the reverse side of the upper and lower veneers, and evenly apply glue on both sides of the other veneers;

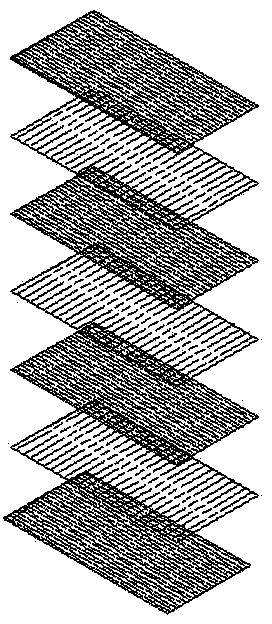

[0046] ⑤. Arrange the veneers coated with glue in a symmetrical arrangement of one vertical and one horizontal. The number of layers is odd. After high temperature and high pressure, one layer is formed into a multi-layer board, which is left for health preservation an...

Embodiment 2

[0051] The flame retardant that flame retardant treatment selects in described step 2. is:

[0052] Flame retardant mixture a: water, triammonium phosphate, borax;

[0053] Solution b: water, zinc nitrate;

[0054] Mixed solution c: water, potassium hydroxide, γ-chloropropyltrimethoxysilane;

[0055] Flame retardant glue d: melamine resin glue, ammonium sulfate;

[0056] The flame retardant treatment steps are:

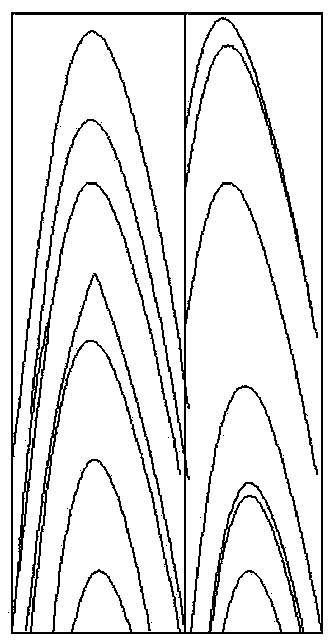

[0057] Ⅰ. Put the veneer with a moisture content of 70% into the flame retardant mixture a and soak for 48 hours, take it out and dry it in the air, and let it dry naturally with a moisture content below 40%. The flame retardant mixture a: water, triammonium phosphate, borax 100 :22:21;

[0058] Ⅱ. Put the veneer obtained in the previous process with a moisture content below 30% into zinc nitrate solution b and soak for 1 hour, take it out and dry it in the air, and let it dry naturally with a moisture content below 30%. Zinc nitrate solution b: wa...

Embodiment 3

[0061] In the steps ④ and ⑥, the glue standard is environmental protection EO grade, the glue concentration is 70%, the choice of glue: melamine resin or phenolic resin glue (PF), etc.; fireproof glue: melamine resin glue, ammonium sulfate, flour 100:0.7:30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com