Preparation method of humidity sensitive grating and fiber bragg grating temperature and humidity sensor

A grating and humidity-sensitive technology, applied in the field of intelligent detection, can solve the problems of stray product performance distribution, fiber grating can not be used to detect relative humidity, process is affected by the environment, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

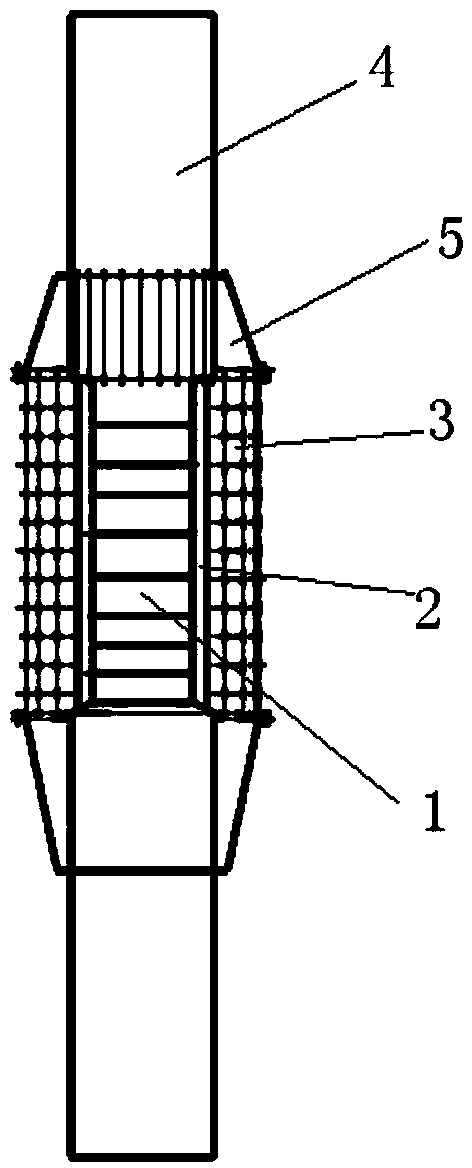

Image

Examples

Embodiment 1

[0034] The invention provides a method for preparing a moisture-sensitive grating, comprising the following steps:

[0035] a. Put the plant fiber into 【AMIM】cl (1-allyl-3-methylimidazolium chloride salt) solution for hydrolysis, and filter out the impurities in the solution to obtain a clean solution;

[0036] b, the cleaning solution is desugared by a certain amount of enone, and the desugared product is added to the acetic acid solution to esterify the hydroxyl functional group of the cellulose to form an acetyl functional group;

[0037] c. Put the grating into a solution made of 3-ATPS (trisilane coupling agent), ethanol and water. The hydroxyl groups on the surface of the grating bond with 3-ATPS to form silane-containing amine groups that are easily bonded to acetyl groups. ;

[0038] d, washing and drying the grating with silane-containing amine groups, soaking it in the solution of acetyl-containing cellulose in step b, to form a moisture-sensitive grating grafted wi...

Embodiment 2

[0041] f, selecting discarded short cotton fibers as fiber raw materials, washing the short cotton fibers, drying them in the air, removing silt and large particles of cotton impurities, then combing and beating at the same time to obtain relatively clean plant fibers;

[0042] a. Put the obtained relatively clean plant fibers into [BMIM]cl (1-butyl-3-methylimidazole oxide) solution for hydrolysis, and filter out the impurities in the solution to obtain a clean solution;

[0043] b, the cleaning solution is desugared by a certain amount of enone, and the desugared product is added to the acetic anhydride solution to esterify the hydroxyl functional group of the cellulose to form an acetyl functional group;

[0044] c. Put the grating into a solution made of 3-ATPS (trisilane coupling agent), ethanol and water. The hydroxyl groups on the surface of the grating bond with 3-ATPS to form silane-containing amine groups that are easily bonded to acetyl groups. ;

[0045] d, washing...

Embodiment 3

[0048] f, selecting discarded short cotton fibers as fiber raw materials, washing the short cotton fibers, drying them in the air, removing silt and large particles of cotton impurities, then combing and beating at the same time to obtain relatively clean plant fibers;

[0049] a. Put the obtained relatively clean plant fibers into [AMIM]cl (1-allyl-3-methylimidazolium chloride salt) solution for hydrolysis, and filter out the impurities in the solution to obtain a clean solution;

[0050] b. Desugaring the cleaning solution with a certain amount of enone, and adding the product after desugaring to nitric acid solution to esterify the hydroxyl functional groups of cellulose to form acetyl functional groups;

[0051] c. Put the grating into a solution made of KH570, ethanol and water, and the hydroxyl groups on the surface of the grating bond with KH570 to form silane-containing amine groups that are easily bonded to acetyl groups;

[0052] d, washing and drying the grating with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com