Preparation method of novel water-absorbing antibacterial bracket composite humidifying material

A water-absorbing material and water-absorbing technology, applied in chemical instruments and methods, wood layered products, synthetic resin layered products, etc., can solve the problems of lack of adjustment of moisture and water vapor, lack of water vapor retention and adsorption, insufficient water absorption and moisture absorption, etc. , to achieve the effect of excellent antibacterial properties, wide application range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

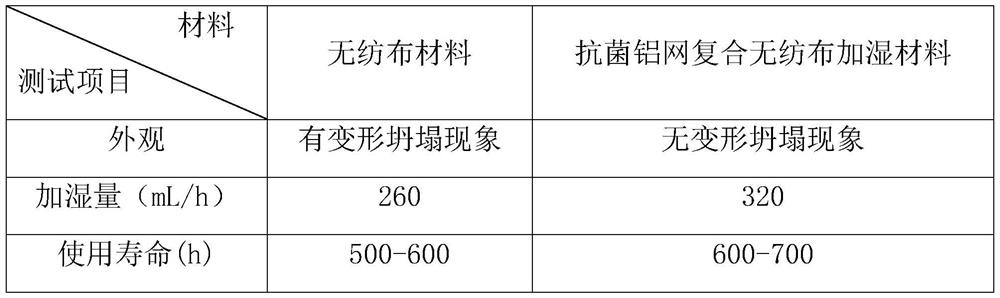

Embodiment 1

[0027] A method for preparing a novel water-absorbing antibacterial aluminum mesh composite non-woven fabric humidifying material, comprising the following steps:

[0028] 1) Pulping: Weigh 50kg water-based EVA emulsion (45% solid content), 1kg polyhexamethylene biguanide PHMB solution (30% solid content), and pour 100kg deionized water into the mixing tank, open the lifting mixer head to Mix at 300-700rpm for 30min to get the mixed slurry;

[0029] 2) Spraying and sizing: Take 10kg of the prepared mixed slurry and pour it into the special barrel for spraying, insert the liquid inlet pipe of the pneumatic spray gun into the barrel, and place the nozzle of the spray gun above and below the feeding position of the water-absorbing non-woven fabric in the spraying box At a distance of 10cm, the water-absorbing non-woven fabric is sent to the spraying box through the feeding roller, the spraying air pressure is adjusted to 0.5MPa, and the air flow is 10m 3 / h, the water-absorbing ...

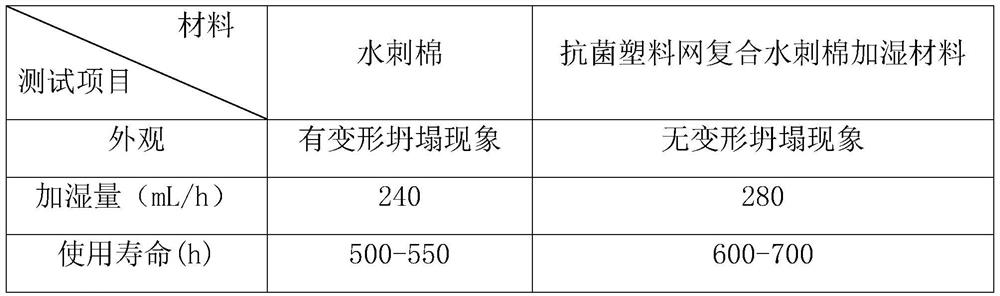

Embodiment 2

[0037] A preparation method of a novel water-absorbing antibacterial plastic net composite spunlace cotton humidification material, comprising the following steps:

[0038] 1) Pulping: 60kg water-based PPA emulsion (53% solid content), 1kg polyhexamethylene monoguanidine PHMG solution (30% solid content), and 100kg deionized water are poured into the mixing tank, and the lifting mixer head is turned on at 300 Mix at -700rpm for 30min to obtain the mixed slurry;

[0039] 2) Dip coating and sizing: Take the prepared 20kg mixed slurry and pour it into the padding tank, send the water-absorbing spunlace cotton to the dipping tank through the feeding roller, and ensure that the water-absorbing spunlace cotton is immersed 2cm below the liquid surface, absorbing water The spunlaced cotton feeding speed is 50cm / min and sent to the counter-roller table through the conveying roller to press out the remaining liquid, and the remaining liquid is collected and reused;

[0040] 3) Hot air ...

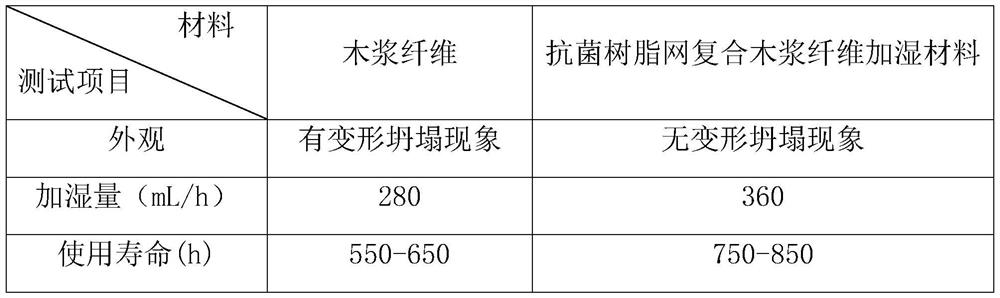

Embodiment 3

[0047] A preparation method of a novel water-absorbing antibacterial resin net composite wood pulp fiber humidifying material, comprising the following steps:

[0048] 1) pulping: take by weighing 40kg water-based EVA emulsion (solid content 45%), 40kg water-based PPA emulsion (solid content 53%), 1kg polyhexamethylene biguanide PHMB solution (30% solid content), 100kg deionized water and pour Put it into the mixing tank, turn on the lifting mixer head and mix at 300-700rpm for 40min to get the mixed slurry;

[0049]2) Spraying and sizing: Take 10kg of the prepared mixed slurry and pour it into the special barrel for spraying, insert the liquid inlet pipe of the pneumatic spray gun into the barrel, and place the nozzle of the spray gun 10cm above and below the feeding position of the water-absorbing wood pulp fiber in the spraying box At the place, the water-absorbing wood pulp fiber is sent to the spraying box through the feeding roller, the spraying air pressure is adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com