Glass wool product packaging production line and glass wool product packaging method

A product packaging and production line technology, applied in the field of packaging, can solve the problems of low efficiency of glass wool packaging, achieve the effects of saving manpower output, convenient and accurate production, and ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

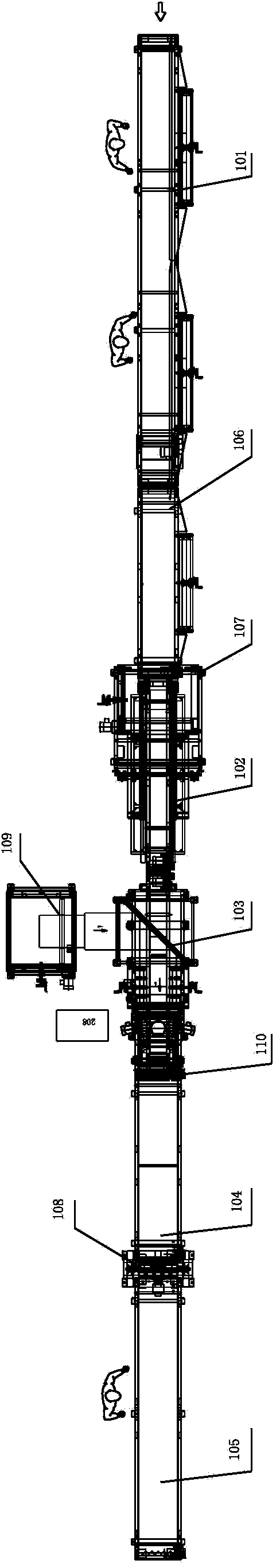

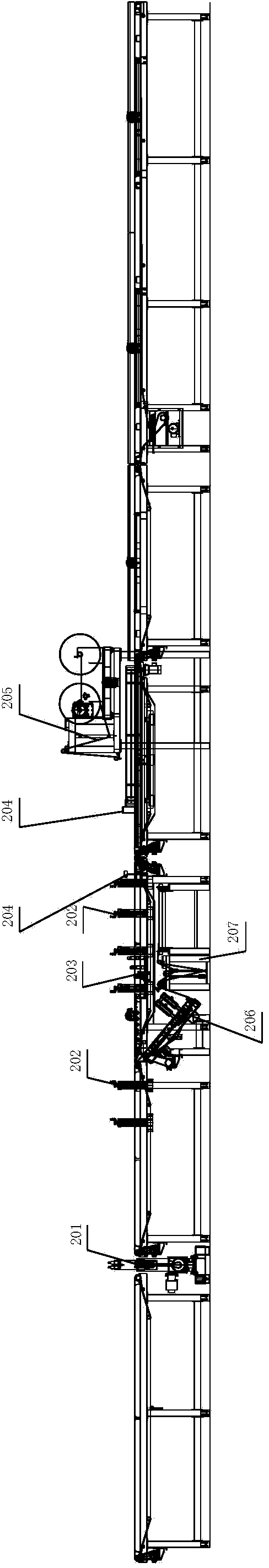

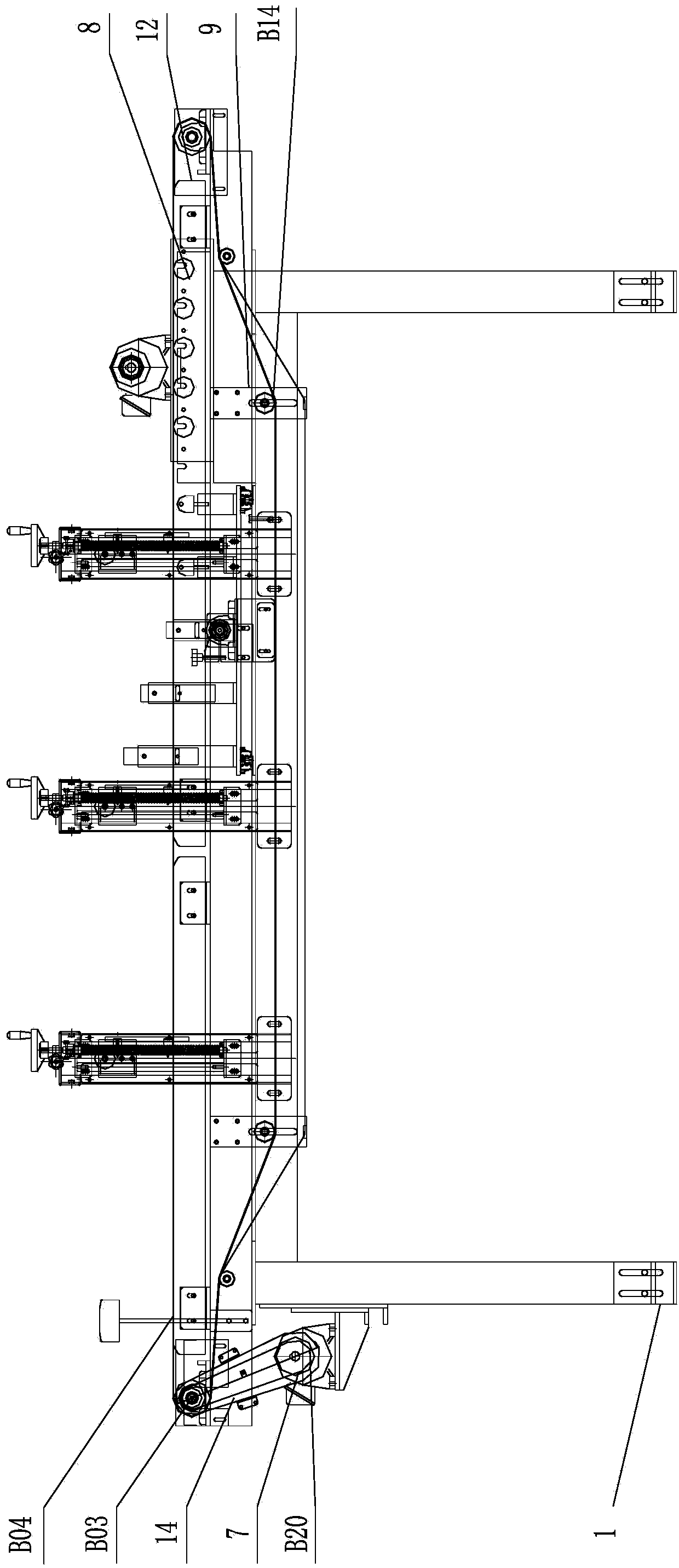

[0024] The present invention relates to a glass wool product packaging production line and a packaging method thereof. The production line mainly includes a feeding belt conveyor 101, a third belt conveyor 106, an automatic punching PE film unwinding device 107, a correction belt conveyor 102, and an edge folding machine. Belt conveyor 103, PE film belt conveyor 110, the first belt conveyor 104, cutting machine 108 and the second belt conveyor 105, the hemming belt conveyor 103 is also connected with automatic PE film unwinding device 109, correcting The belt conveyor 102 is connected with an automatic punching PE film unwinding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com