Method for preparing copper-based catalyst for synthesizing organosilicone monomer

A technology of copper-based catalyst and organosilicon, which is applied in organic chemistry, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of process stability to be improved, unstable catalytic performance, and catalyst hardening, etc., to achieve ternary The effect of convenient component content, easy control of process parameters and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

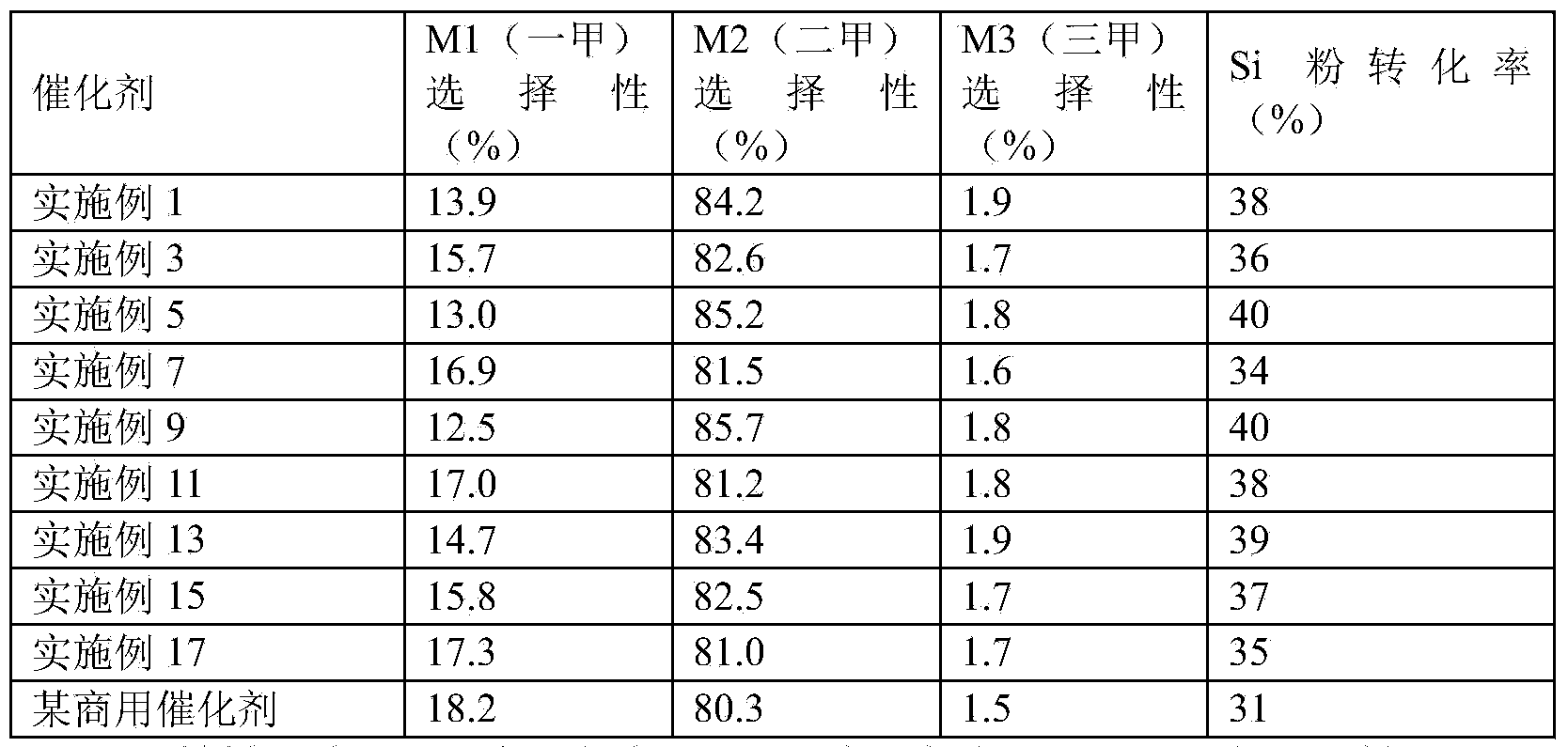

Examples

Embodiment 1

[0032] Step 1, dissolving 0.49kg copper sulfate pentahydrate in deionized water, heating to make a copper sulfate solution with a temperature of 80°C and a concentration of 0.31kg / L;

[0033] Step 2, dissolving 0.25kg of sodium carbonate in 2L of deionized water and heating to make an alkaline solution with a temperature of 100°C;

[0034] Step 3: Add the copper sulfate solution described in Step 1 to the alkaline solution described in Step 2 under stirring conditions, and react at a temperature of 80° C. to form gray-black precipitates; collect the precipitates by filtration and dry them.

[0035] Step 4. Dry the precipitate collected in step 3 and place it in a fluidized bed reactor. Use a mixture of hydrogen and nitrogen as a reducing medium, and use a temperature-programmed reduction method for reduction: first preheat to 150°C; then adopt a temperature program, the heating rate is 30°C / h, and the final reduction temperature is 250°C. When the final temperature is reached,...

Embodiment 2

[0040] This embodiment is the same as Example 1, except that the basic compound is bicarbonate, hydroxide or ammonia, or at least two of carbonate, bicarbonate, hydroxide and ammonia. kind.

Embodiment 3

[0042] Step 1, dissolving 0.7kg anhydrous copper nitrate in deionized water, heating to make a copper nitrate solution with a temperature of 50°C and a concentration of 0.7kg / L;

[0043] Step 2. Dissolve 0.31kg of sodium hydroxide in 1L of deionized water and heat to make an alkaline solution with a temperature of 80°C;

[0044] Step 3: Add the copper salt solution described in Step 1 to the alkaline solution described in Step 2 under agitation, react at a temperature of 50° C. to 100° C. to form precipitates; collect the precipitates by filtration and dry.

[0045] Step 4. Dry the precipitate collected in step 3 and place it in a fluidized bed reactor. Use a mixture of hydrogen and nitrogen as a reducing medium, and use a temperature-programmed reduction method for reduction: first preheat to 150°C; then use temperature programming, the heating rate is 30°C / h, the final reduction temperature is 200°C, and when it reaches 200°C, keep it for 3 hours; the initial hydrogen concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com