Sieve plate-free fluidized bed as well as preparation method of boron trichloride

A boron trichloride, sieve-free technology, applied in chemical instruments and methods, boron halide compounds, boron halides, etc., to achieve the effects of simple equipment, improved production efficiency, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

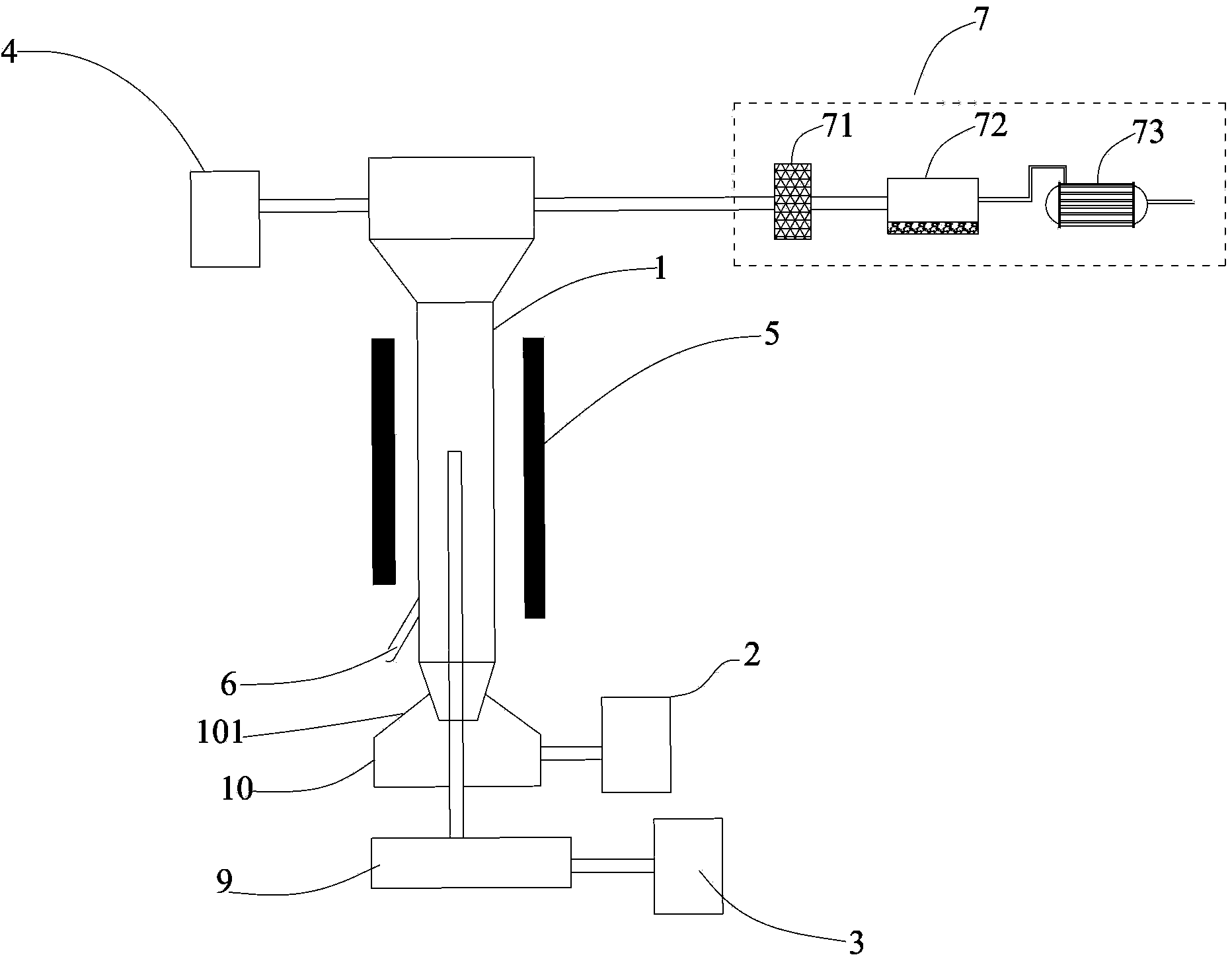

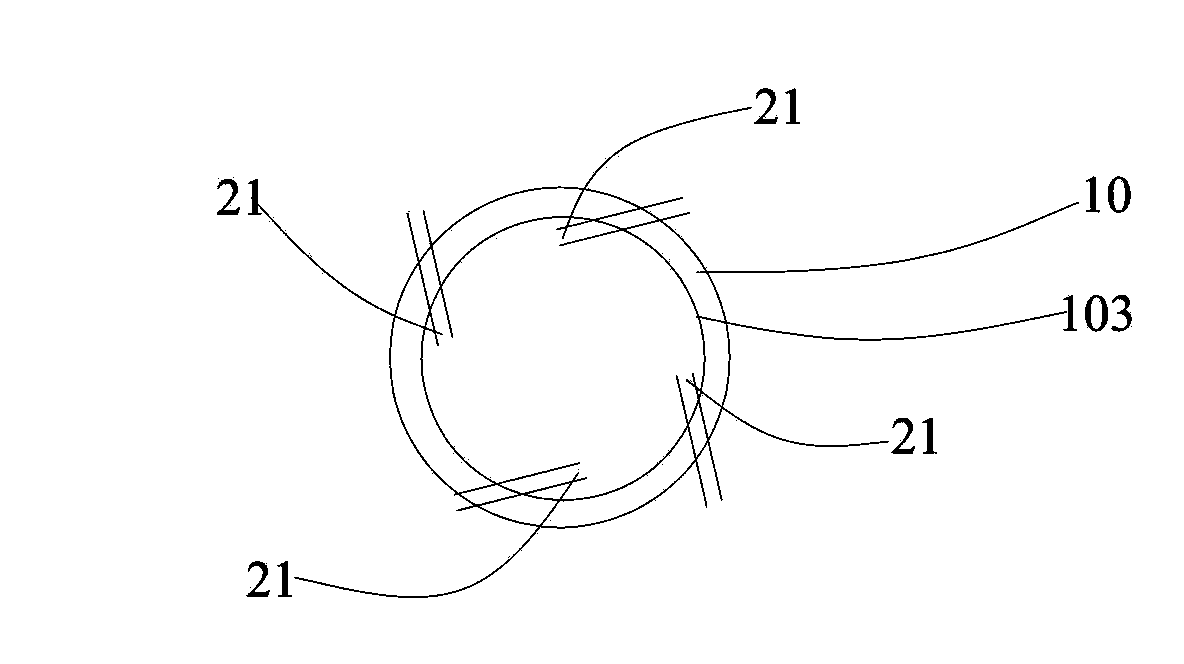

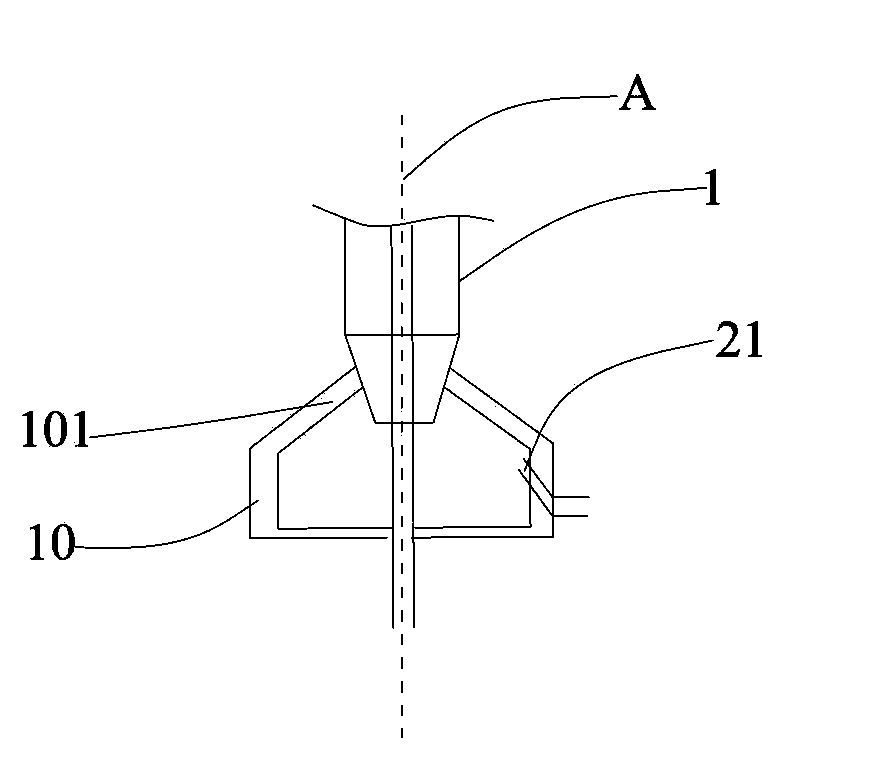

[0032] The preparation method of boron trichloride according to the second aspect of the present invention adopts the fluidized bed without sieve plates described in the first aspect above, and the preparation method of boron trichloride includes: passing the powder raw material alkaline earth metal boride through The raw material supply device 4 is filled in the bed body 1 of the fluidized bed device without a sieve plate; the carrier gas source 2 is opened, and the carrier gas is passed into the bed body 1 of the fluidized bed device without a sieve plate, so that the powder raw material is The bed body 1 of the fluidized bed device without a sieve plate is in a fluidized state; the heating device 5 is turned on to heat the bed body 1, and after the temperature reaches the specified temperature, the reaction gas anhydrous hydrogen chloride is introduced; after the reaction reaches the specified period of time , open and start the separation device 7, to obtain the required bo...

Embodiment 1

[0050] Fill calcium hexaboride powder with a particle size of 20-30 mesh in the bed body 1 of a fluidized bed without a sieve plate through the raw material supply device 4 at a flow rate of 80 g / h; open the carrier gas source 2, and pass nitrogen gas into the In the bed body 1 of the fluidized bed of the sieve plate, the powder calcium hexaboride is in a fluidized state in the bed body 1 of the fluidized bed without the sieve plate; open the heating device 5 to heat the bed body 1, and when the temperature reaches 550 After ℃, the reaction gas anhydrous hydrogen chloride, which is dehydrated and dried by the reaction gas treatment device 9, is passed into the bed body 1 at a flow rate of 500g / h, and the nitrogen flow rate is continuously reduced to maintain the fluidized state of calcium boride, and the reaction is performed for 1 hour; then open And start the separation device 7, separate calcium chloride slag and calcium boride through the filter column that the glass fiber ...

Embodiment 2

[0052] Fill the 100~120 mesh powdered calcium hexaboride in the bed 1 of the fluidized bed without sieve plate through the raw material supply device 4 at a flow rate of 85g / h; open the carrier gas source 2, and pass argon gas into the sieve plate-free fluidized bed In the bed body 1 of the fluidized bed, the powdered calcium hexaboride is in a fluidized state in the bed body 1 of the fluidized bed without sieve plates; the heating device 5 is turned on to heat the bed body 1, and after the temperature reaches 700°C , feed the reaction gas anhydrous hydrogen chloride, which is dehydrated and dried by the reaction gas treatment device 9, into the bed body 1 at a flow rate of 600g / h, and at the same time continuously reduce the flow rate of argon to maintain the fluidized state of calcium boride, and react for 1.5h; then open And start the separation device 7, separate the calcium chloride slag and calcium boride through the filter column that the glass fiber in the gas-solid sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com