Transparent ceramic, method for manufacturing same, and magneto-optical device

A technology of transparent ceramics and manufacturing methods, applied in chemical instruments and methods, optical components, instruments, etc., can solve problems such as reduction of extinction ratio, achieve small component changes, less scattering, and reduce heterogeneous precipitates or pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~63 and comparative example 1~15

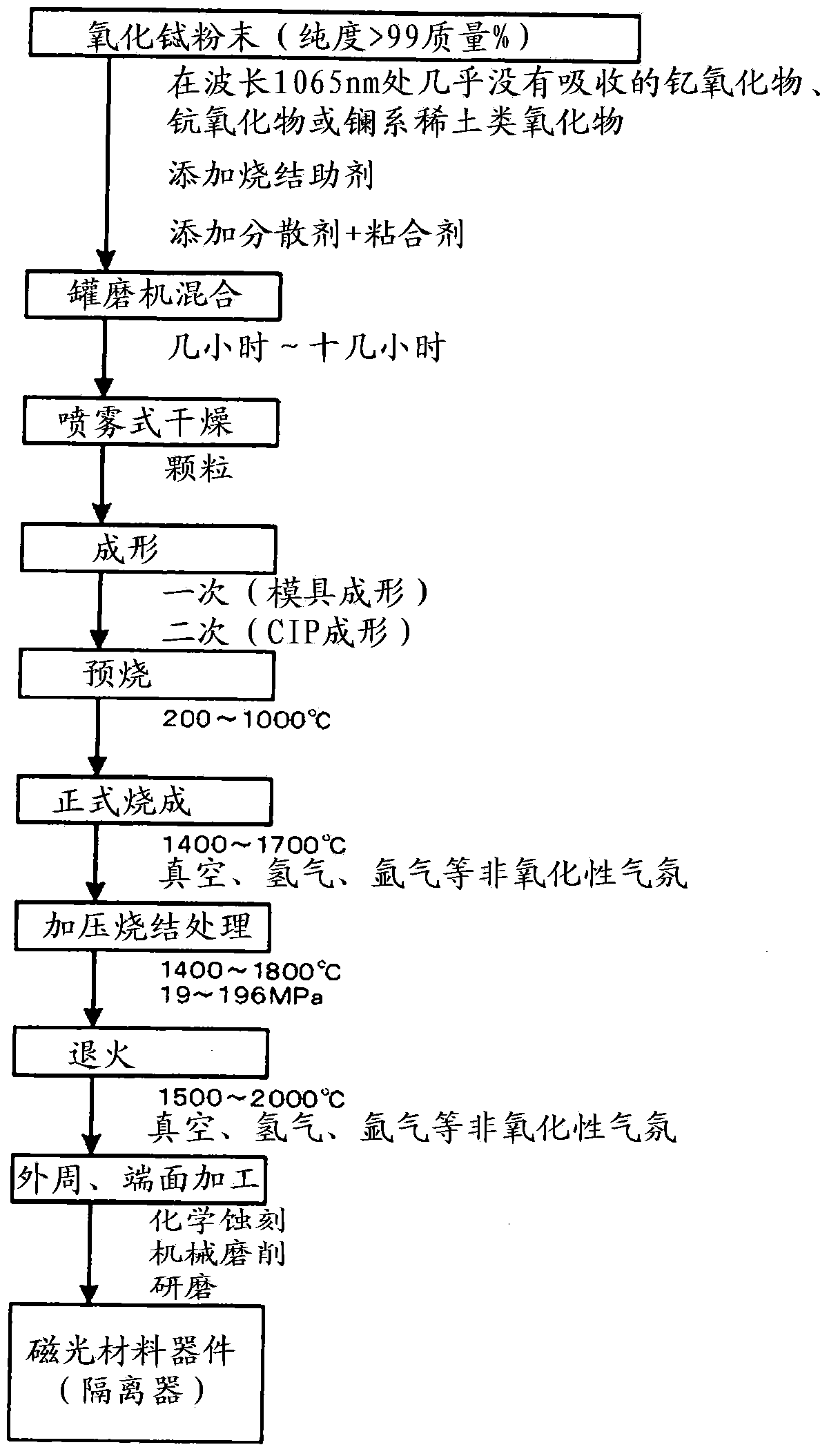

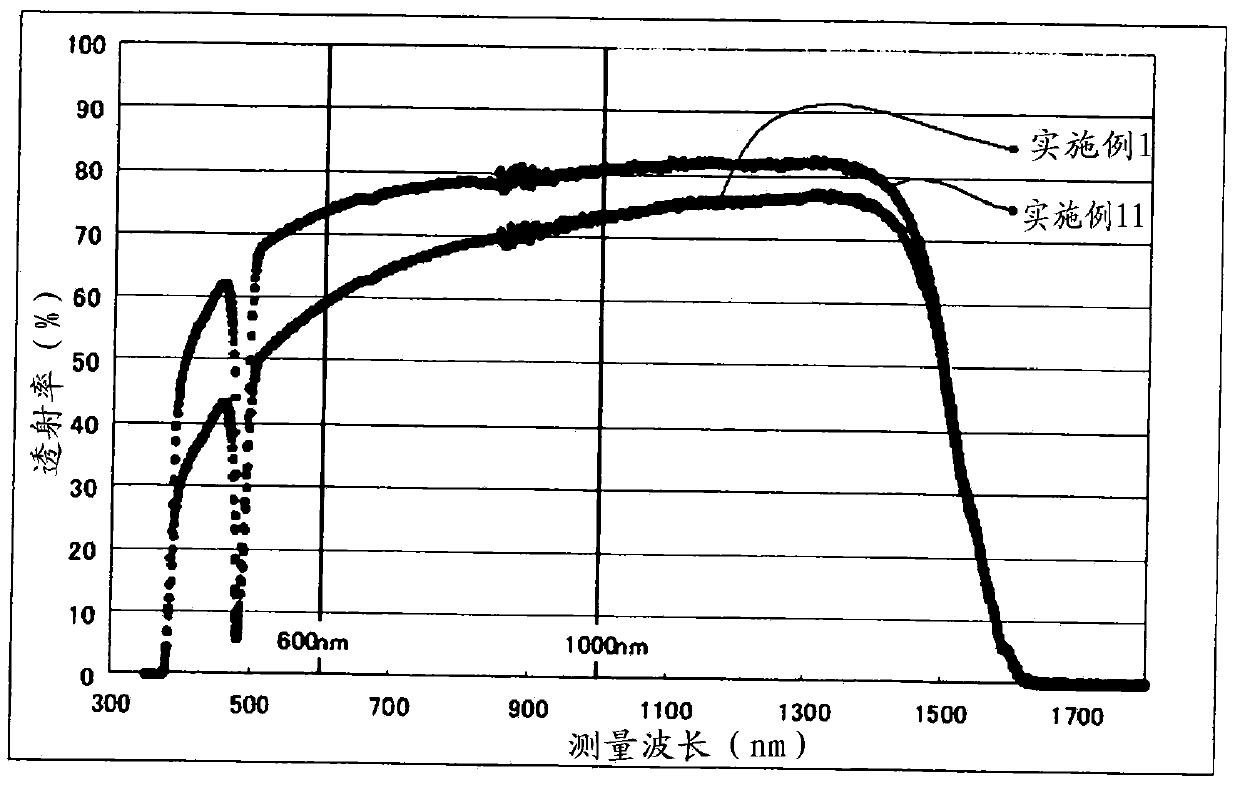

[0160] According to the method shown in FIG. 1 , according to the raw materials and conditions shown in Tables 1-7 (Example) and Tables 8-9 (Comparative Examples), transparent rare earth oxide ceramics containing terbium oxide were produced respectively. In addition, Examples 1-9 did not perform annealing.

[0161] A predetermined amount of sintering aid was added to each raw material powder as a dispersant and a binder, and effective amounts of ethyl cellulose and polyvinyl alcohol were added, and then mixed by a pot mill to obtain a mixture. Then, the above-mentioned mixture is spray-dried to obtain particles with a particle diameter of several tens of micrometers. Using the above-mentioned pellets, mold molding is performed as primary molding, and then CIP is performed as secondary molding to obtain a molded body. The obtained compact is calcined at 200 to 1000° C. in the air, and then fired at 1600 to 1800° C. in a predetermined atmosphere (main firing). Next, the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com