Rotary machine fault detection method of dual-tree complex wavelet transformation with adjustable quality factors

A dual-tree complex wavelet and quality factor technology, applied in the testing of mechanical components, vibration measurement in solids, testing of machine/structural components, etc., can solve problems such as inaccurate periodic information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

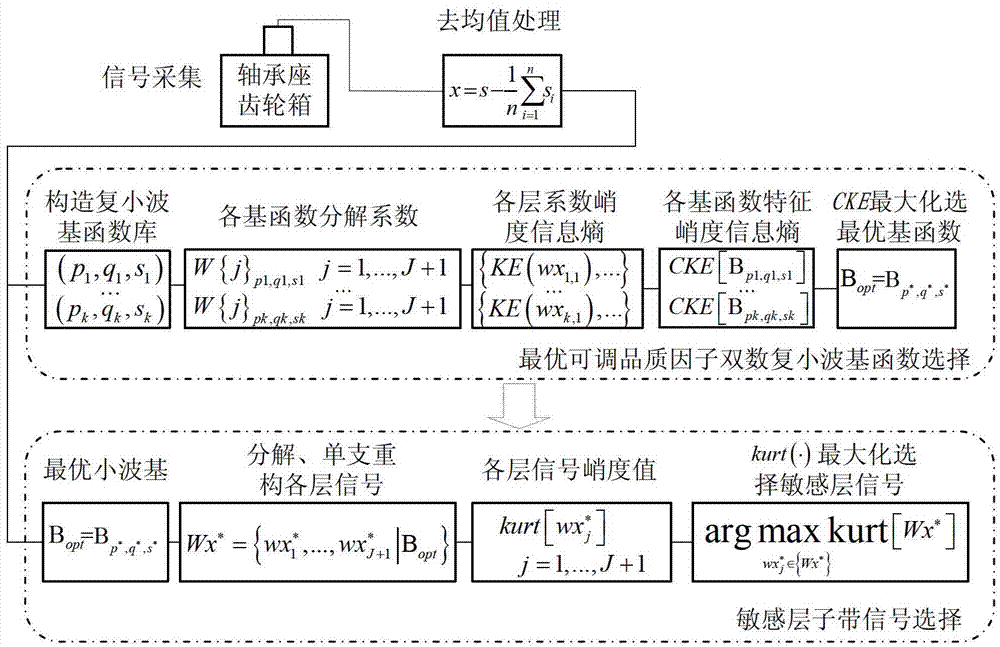

[0059] combine Figure 1 to Figure 7 , the rotating machinery fault detection method based on the adjustable quality factor dual-tree complex wavelet transform of the present invention, such as figure 1 As shown, its main steps include:

[0060] Step 1: Signal acquisition and preprocessing, including:

[0061] a. Arrange vibration sensors on electromechanical equipment to collect vibration response signals of monitoring objects;

[0062] b. Perform de-average processing on the collected signal x to obtain a preprocessed signal x that eliminates the DC component (1) ,Expressed as:

[0063] x ( 1 ) = x - 1 n Σ i = 1 n x i

[0064] Among them, n is the length of the x sequence, x i for each sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com