Flexible composite tube and manufacturing method thereof

A technology of flexible composite pipes and inner layer pipes, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of poor pressure bearing capacity of composite pipes, easy delamination of inner pipes and reinforcement layers, and easy creep of composite pipes. Achieve the effects of avoiding creep, good barrier and anti-swelling properties, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

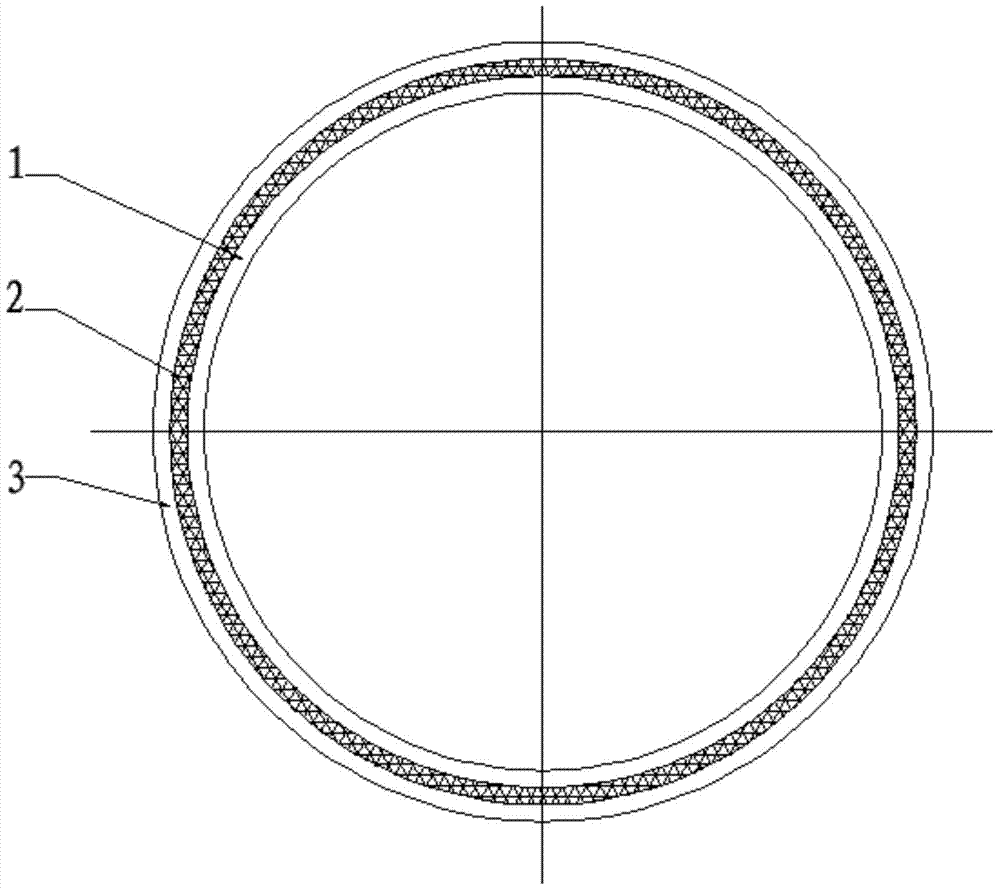

[0037] Such as figure 1 As shown, the embodiment of the present invention provides a flexible composite pipe, the flexible composite pipe includes: an inner pipe, a reinforcement layer and an outer pipe, the inner pipe is the innermost layer of the flexible composite pipe, and the inner pipe is connected to the The substance to be transported is in direct contact with the material to be transported, and the substance to be transported flows in the inner tube. The reinforcement layer is between the inner tube and the outer tube. The reinforcement layer is used to increase the strength of the flexible composite tube. The outer tube is the outermost layer of the flexible composite tube. The layer tube is used to protect the inner layer tube and play the role of anti-scratch, anti-static and flame retardant;

[0038] Wherein, the percentage of various components in the inner tube is the percentage of the mass of each component in the inner tube to the total mass, and the percentag...

Embodiment 2

[0062] An embodiment of the present invention provides a method for preparing a flexible composite pipe, the preparation method comprising:

[0063] (1) Preparation of inner tube

[0064] Step 1: Copolymerize 60-85% polyvinylidene fluoride, 8-25% polyethylene, 3-6% polyethylene grafted difluoromaleic anhydride, and 5-10% ethylene-propylene according to mass percentage and 0.3-0.6% antioxidant into the high-speed mixing tank, so that the above materials are mixed evenly and the inner tube material is obtained;

[0065] Step 2: Put the material of the inner tube into the twin-screw extruder for mixing. The twin-screw extruder is divided into the first section, the second section, the third section, the fourth section and the fifth section. The first section and The extrusion temperature of the second section is 150-170°C, the extrusion temperature of the third, fourth, and fifth sections is 170-200°C, and the extruder speed of the twin-screw extruder is 300-350r / min. The total...

Embodiment 3

[0077]The embodiment of the present invention provides a flexible composite pipe and its preparation method, the flexible composite pipe and its preparation method comprising:

[0078] (1) Preparation of inner tube

[0079] Step 1: Weigh the raw materials of the corresponding components according to the following mass percentages, among them, 64% polyvinylidene fluoride, 24% high-density polyethylene, 5.2% polyethylene grafted difluoromaleic anhydride, 6.5% ethylene-propylene copolymer material, 0.3% antioxidant, and the raw materials of each component are added into the high-speed mixing tank and mixed evenly to obtain the inner tube material;

[0080] Step 2: Add the material of the inner layer tube into the twin-screw extruder for mixing. The twin-screw extruder is divided into the first section, the second section, the third section, the fourth section and the fifth section. The exit temperature is T1=150°C, the extrusion temperature of the second stage is T2=160°C, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com