Novel method for producing reinforced wood-plastic composite floor

A wood-plastic composite and wood-plastic floor technology is applied in the field of building decoration materials, which can solve the problems of unsatisfactory adhesion and inability to match the use of alumina tri-alumina wear-resistant paper, and achieve high physical and chemical properties, low production cost, and good durability. The effect of corrosion and insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

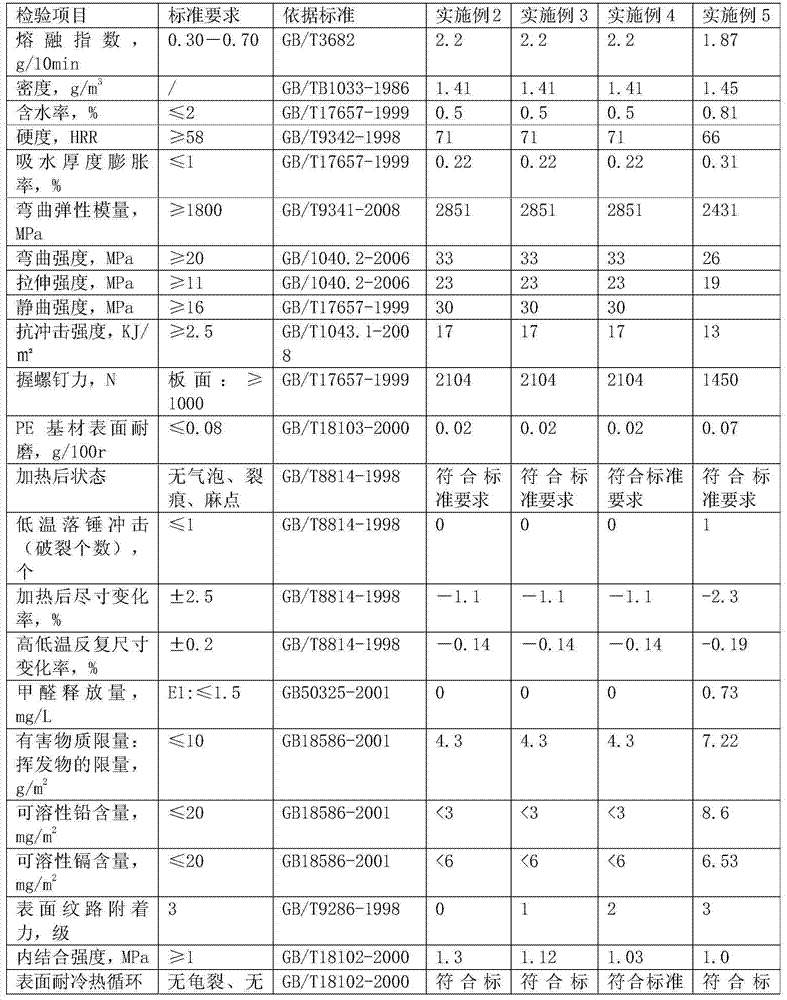

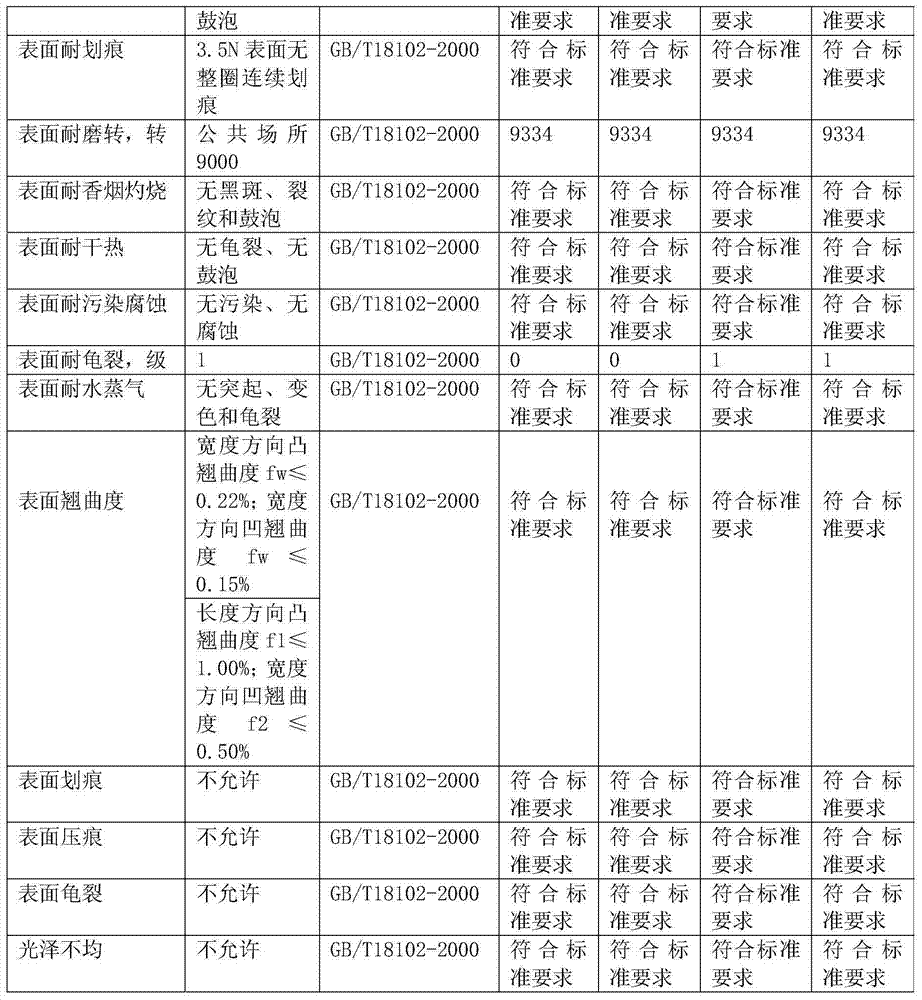

Examples

Embodiment 1

[0033] Embodiment 1: Production of wood-plastic floor substrate

[0034] 1) Take each component according to the following weight ratio, and set aside:

[0035] 100 parts by weight of wood flour, 45 parts by weight of waste polyethylene, 10 parts by weight of waste polypropylene, 2.5 parts by weight of calcium-zinc composite stabilizer, 15 parts by weight of light calcium carbonate, high-efficiency composite adhesive LEPHF (Kunshan Magison Composite Materials Co., Ltd. Produced by the company) 5 parts by weight, 0.6 parts by weight of stearic acid, 0.8 parts by weight of PE wax, 0.2 parts by weight of antioxidant KY-1010, 0.2 parts by weight of ultraviolet absorber UV-531 (manufactured by Nanjing Hualiming Chemical Co., Ltd.), HD3303 (produced by Kunshan Diying Composite Materials Co., Ltd.) 2 parts by weight, titanate coupling agent NDZ-102 (produced by Nanjing Shuguang Chemical Factory) 2 parts by weight, polyol benzoate 2 parts by weight, chloromethoxy Fatty acid ester (pr...

Embodiment 2

[0039] Embodiment 2: Making reinforced wood-plastic floor

[0040] 1) Making wood-plastic floor substrate:

[0041] With embodiment 1;

[0042]2) Make a decorative layer on the surface of the wood-plastic floor substrate by the hydraulic bonding process:

[0043] a) Purchase water-resistant printing film (select the printing film with specific grain patterns according to the needs), cut it into several pieces slightly larger than the surface area of the wood-plastic floor substrate, and set aside;

[0044] b) Weigh 1 part by weight of methyl isobutyl ketone, 3 parts by weight of cyclohexanone, 1.5 parts by weight of isopropanol, 0.5 parts by weight of ethylene glycol butyl ester, 11 parts by weight of butyl acetate, and 2 parts by weight of ethyl acetate, 30 parts by weight of xylene, 14 parts by weight of banana water, 8 parts by weight of methyl acetate, 3 parts by weight of polyol benzoic acid ester, 2 parts by weight of methyl ethyl ketone, 2 parts by weight of varnish...

Embodiment 3

[0050] Embodiment 3: Making reinforced wood-plastic floor

[0051] 1) Making wood-plastic floor substrate:

[0052] With embodiment 1;

[0053] 2) Make a decorative layer on the surface of the wood-plastic floor substrate by the hydraulic bonding process:

[0054] Repeat embodiment 2, difference is that surface-active solvent is obtained by mixing the raw materials of following weight parts:

[0055] 2.5 parts by weight of methyl isobutyl ketone, 3.5 parts by weight of cyclohexanone, 1 part by weight of isopropanol, 1 part by weight of butyl ethylene glycol, 21 parts by weight of butyl acetate, 1 part by weight of ethyl acetate, 28 parts by weight of xylene Part, 10 parts by weight of banana water, 12 parts by weight of methyl acetate, 18 parts by weight of polyol benzoate, 1 part by weight of butanone, 2.5 parts by weight of varnish (UV varnish);

[0056] 3) Use an adhesive to bond the wear-resistant layer on the surface of the decorative layer:

[0057] Repeat Example 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com