Preparation method of carbon nano-tube based Fenton-like catalyst for advanced oxidation system

A carbon nanotube, advanced oxidation technology, applied in physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of increasing difficulty, high wastewater treatment cost, and fast reaction speed, reducing Secondary environmental pollution, avoidance of secondary environmental pollution, and the effect of adsorption promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

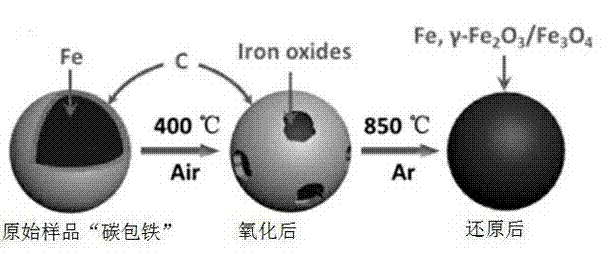

[0030] Put the iron-containing carbon nanotubes of the original sample into a quartz boat, carry out oxidation treatment in an argon atmosphere, raise the temperature to 400°C at a rate of 10°C / min, and heat for 1 hour; then put the obtained sample into a quartz boat, Reduction treatment was carried out under the atmosphere, the temperature was raised to 850°C at a rate of 10°C / min, and heated for 1 hour to obtain a pretreated sample. like figure 1 As shown, the oxidation process is to oxidize the external carbon in the original sample "carbon-coated iron" and promote destruction, so that the internal iron in the "carbon-coated iron" will be exposed, and the elemental iron will be oxidized at the same time. The reduction process uses the oxidation of the iron in the previous step, so that the iron oxide and the carbon wrapped in the outside undergo a reduction reaction again, further consuming the carbon around the iron, and the inner iron in the "carbon-coated iron" is more ...

Embodiment 2

[0033]Put the iron-containing carbon nanotubes of the original sample into a quartz boat, carry out oxidation treatment in an argon atmosphere, raise the temperature to 400°C at a rate of 10°C / min, and heat for 1 hour; then put the obtained sample into a quartz boat, Reduction treatment was carried out under the atmosphere, the temperature was raised to 850°C at a rate of 10°C / min, and the pretreated sample was obtained by heating for 1 hour; the pretreated sample and sulfur were mixed uniformly according to the mass ratio of 2:1, and the mixture was put into a quartz boat and heated under argon gas. Carry out sulfuration treatment under the atmosphere, heat up to 600°C at a rate of 10°C / min, heat for 1 hour, and obtain a mixed sample; put the obtained mixture into a sodium sulfide solution, ultrasonicate, and after the remaining sulfur has completely reacted, filter it with suction, and the obtained The solid is dried to obtain a carbon nanotube-based Fenton-like advanced oxid...

Embodiment 3

[0035] Put the iron-containing carbon nanotubes of the original sample into a quartz boat, carry out oxidation treatment in an argon atmosphere, raise the temperature to 400°C at a rate of 10°C / min, and heat for 1 hour; then put the obtained sample into a quartz boat, Reduction treatment was carried out under the atmosphere, the temperature was raised to 850°C at a rate of 10°C / min, and the pretreated sample was obtained by heating for 1 hour; the pretreated sample and sulfur were mixed uniformly according to the mass ratio of 2:1, and the mixture was put into a quartz boat and heated under argon gas. Carry out sulfuration treatment under the atmosphere, heat up to 600°C at a rate of 10°C / min, heat for 1 hour, and obtain a mixed sample; put the obtained mixture into a sodium sulfide solution, ultrasonicate, and after the remaining sulfur has completely reacted, filter it with suction, and the obtained The solid is dried to obtain a carbon nanotube-based Fenton-like advanced oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com