Preparation method of modified polyether sulfuryl hydrophobic film for gas-liquid film contactor

A hydrophobic membrane and polyethersulfone technology, which is applied in the field of preparation of modified polyethersulfone-based hydrophobic membranes, can solve the problems of gas-liquid membrane contactors with modified polyethersulfone membranes, and achieve good chemical stability , increase surface roughness, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The solvent required for the preparation of the polyethersulfone-based membrane includes one or two mixed additions of dimethylacetamide, dimethylformamide, N-methylpyrrolidone, dimethyl sulfoxide, and triethyl phosphate solvent. The additives used include at least one of polyethylene glycol, ethylene glycol, glycerol, anhydrous lithium chloride, octanol, cyclohexanol and the like. Wherein, the composition of the casting solution includes 10-30 wt.% of polyethersulfone, 5-16 wt.% of additive, and 54-85 wt.% of solvent.

[0035] The preparation raw material of described sol-gel liquid comprises silicate, ammoniacal liquor, dehydrated alcohol, and wherein silicate comprises tetraethyl orthosilicate (TMOS), tetraethyl orthosilicate (TEOS) and polyalkoxysilane One of them; raw materials for the preparation of fluorinated liquid include low surface energy fluorine-containing siloxane, ammonia water, and absolute ethanol. The fluorine-containing siloxane includes one of dode...

Embodiment 1

[0039] (1) The present invention adds 10wt.% polyethersulfone, 5wt.% additive polyethylene glycol 400 (PEG400) and 85wt.% solvent dimethylacetamide (DMAc) into a three-necked flask, and stirs evenly at 60°C for 3h As above, the casting solution was obtained. The polyethersulfone-based membrane was prepared by immersion precipitation phase inversion method. Soak in pure water for 2-3 days, take out and dry for later use.

[0040] (2) Add 98% absolute ethanol by volume and 1% ammonia by volume into a three-necked flask, stir for 30 minutes below 30°C, and mix evenly; then add 1% orthosilicate methyl ester dropwise , Stir for more than 3h, it is a white uniform sol. Pour it into a beaker and let it stand for 8 hours; soak the dried polyethersulfone base film in the sol-gel solution for 5 minutes, rinse it with absolute ethanol after taking it out, and let it dry naturally. The dried film was placed in an oven for heat treatment at T=50°C for 30min.

[0041] (3) Add 98% absolu...

Embodiment 2

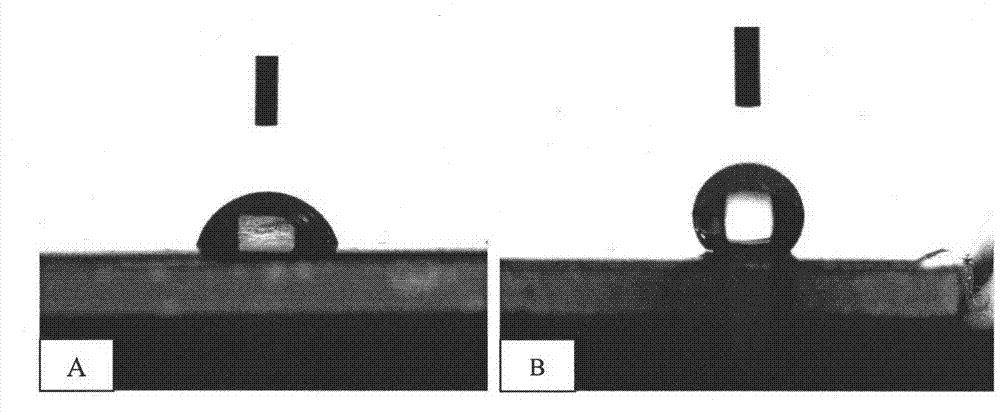

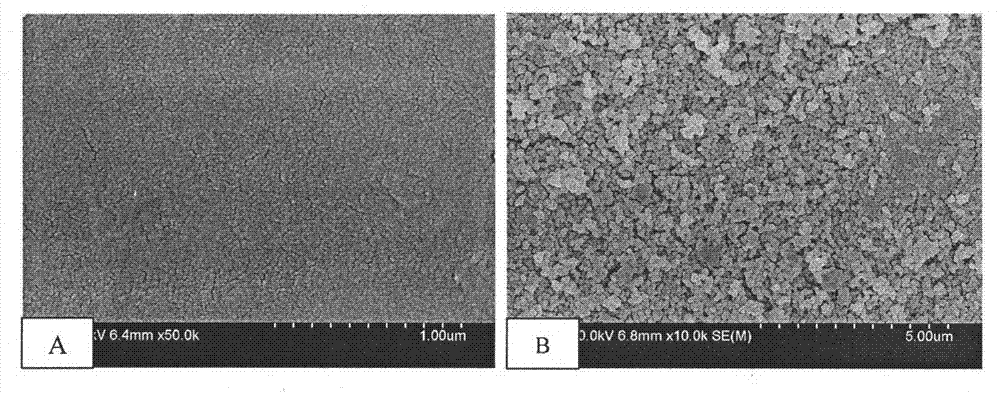

[0044] (1) The present invention adds 16wt.% polyethersulfone, 16wt.% additive polyethylene glycol 400 (PEG400) and 68wt.% solvent dimethylacetamide (DMAc) into a three-necked flask, and stirs evenly at 60°C for 3h As above, the casting solution is obtained. The polyethersulfone-based membrane was prepared by immersion precipitation phase inversion method. Soak in pure water for 2-3 days, take out and dry for later use. In this example, the thickness of the polyethersulfone base film prepared in this example is about 110 μm, and the air permeability of the polyethersulfone base film after drying is measured to be 253.2 m 3 / m 2 h, the surface contact angle is 78° as attached figure 1 As shown in (A), the field emission electron microscope image of the unmodified polyethersulfone membrane surface is shown in the attached figure 2 (A) shown.

[0045] (2) Add 90% absolute ethanol by volume and 5% ammonia by volume into a three-necked flask, stir for 30 minutes below 60°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com