Automatic free-range chicken feeding device

A technology for automatic feeding and free-range chicken farming, which is applied in the poultry industry, application, animal husbandry and other directions, and can solve problems such as being unsuitable for free-range farming and only suitable for cage farming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

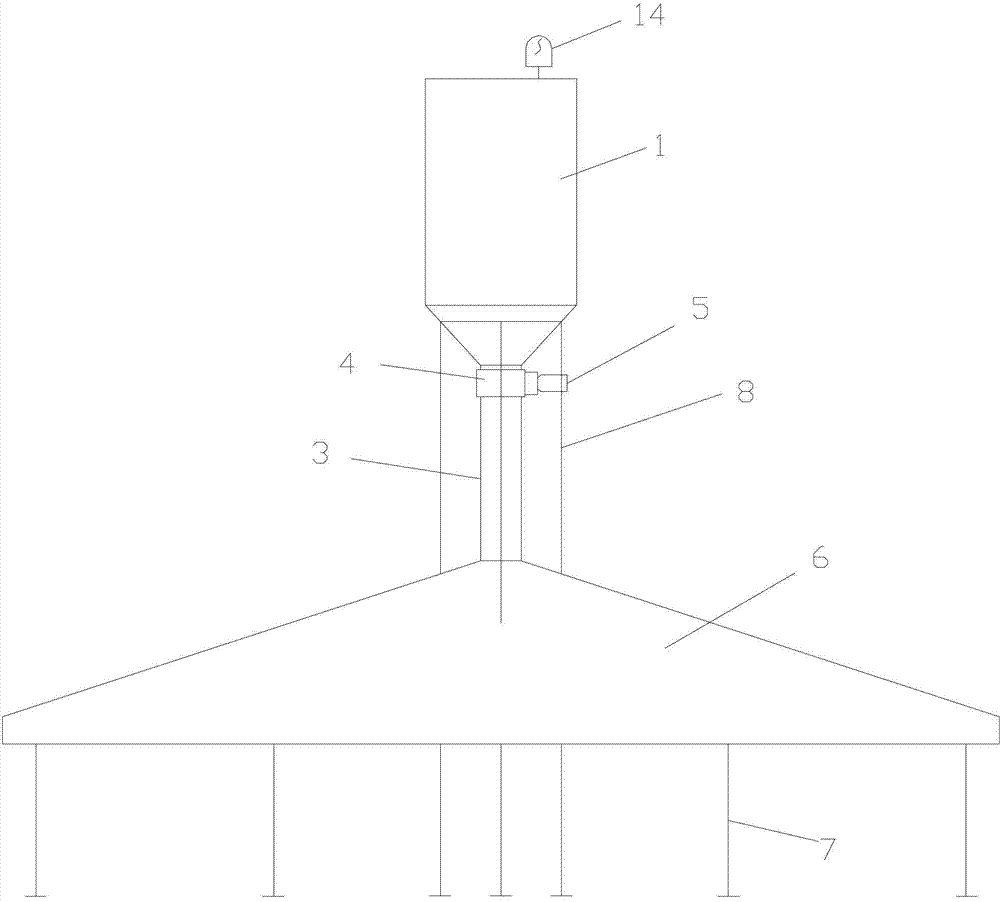

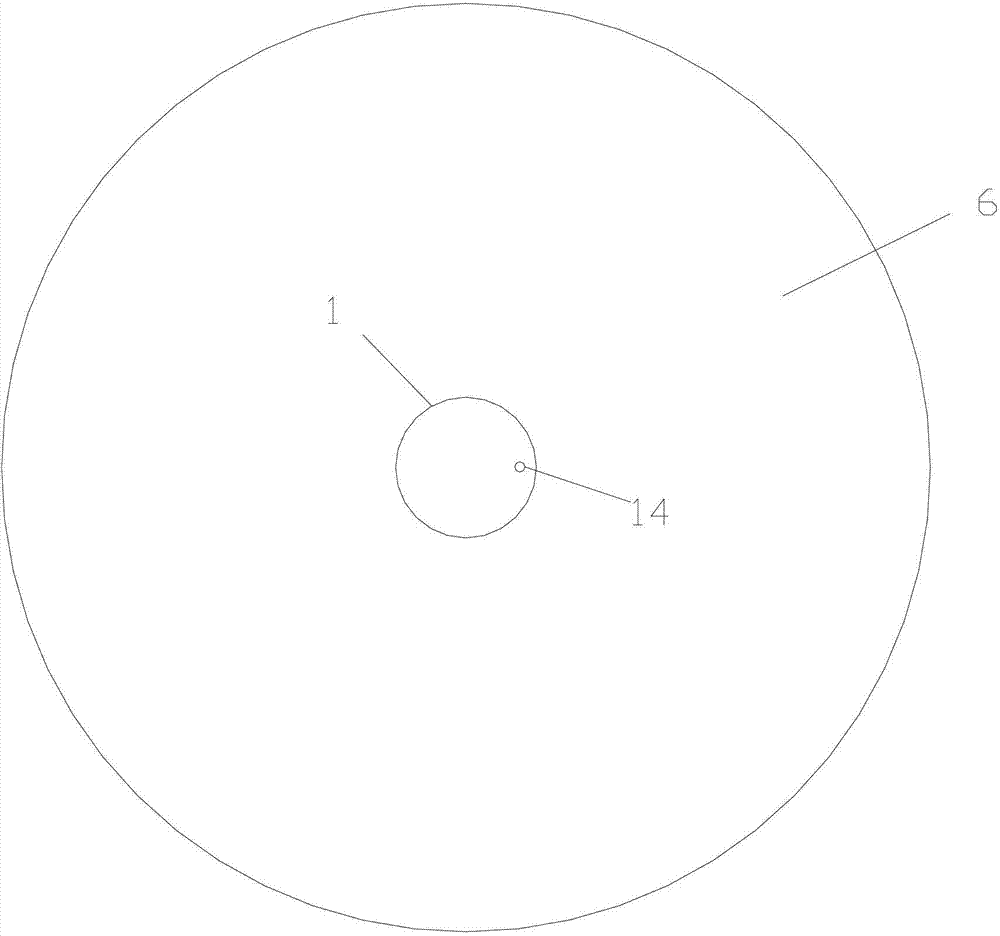

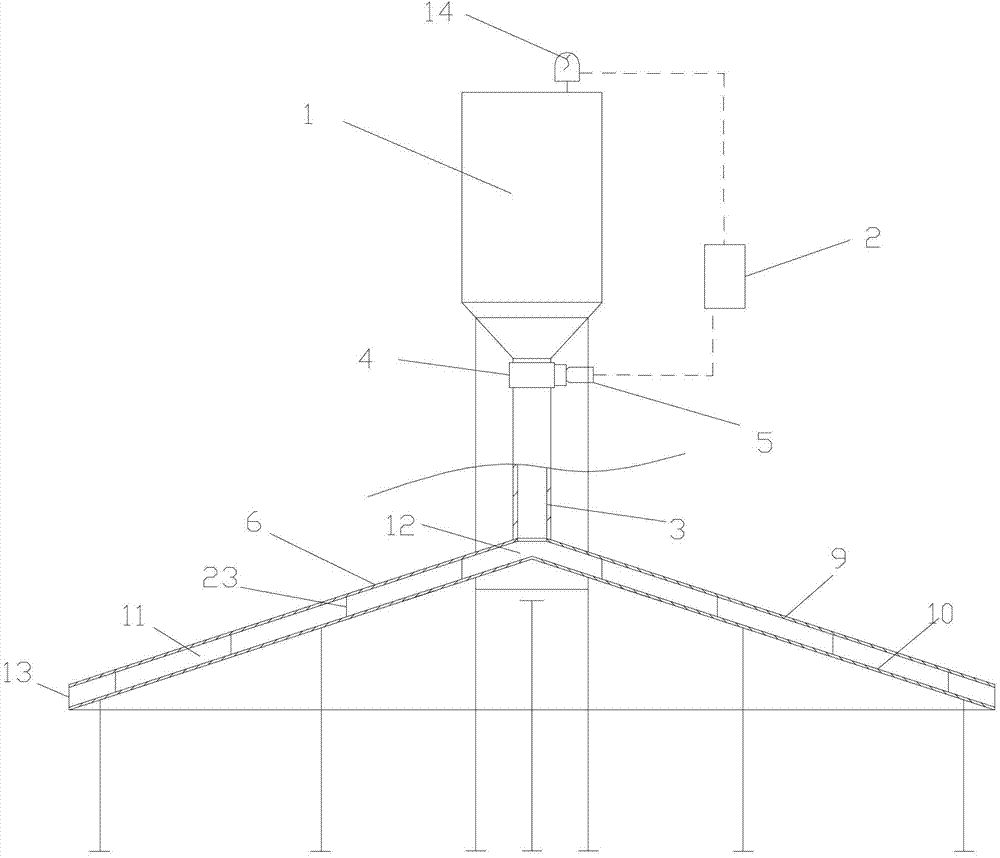

[0032] Such as figure 1 , 2 , 3, the automatic feeding device for free-range chickens described in this embodiment includes a feed bin 1 and a controller 2, the lower part of the feed bin 1 is provided with a feeding pipe 3, and the feeding pipe 3 is provided with a rotary feeding valve 4. The rotary feeding valve 4 is connected to the feeding motor 5 through transmission. A conical top 6 is provided at the bottom of the feeding pipe 3, and a support rod 7 is provided below the conical top 6. The feed bin 1 is fixed on a through-hole On the bracket 8 that passes through the conical top 6; the conical top 6 is composed of an upper conical surface 9 and a lower conical surface 10 that are parallel to each other and distributed up and down, between the upper conical surface 9 and the lower conical surface 10 There are connecting ribs 23, the area between the upper cone surface 9 and the lower cone surface 10 is the blanking gap 11, the feed port 12 of the blanking gap 11 communi...

Embodiment 2

[0035] Such as Figure 4 , 5 , 6, the automatic feeding device for free-range chickens described in this embodiment is different from Embodiment 1 in that an impeller 15 is provided above the cone top of the lower cone surface 10, and an impeller 15 is provided below the impeller 15. Drive its rotating material distribution motor 16; the controller 2 controls the material distribution motor 16 to work.

[0036] During work, the controller 2 controls the feeding motor 5 and the feeding motor 16 to work, and the feeding valve 4 is rotated under the drive of the feeding motor 5, and the feed in the silo falls into the feeding pipe 3, and the impeller 15 is in the distribution process. Driven by the motor 16 to rotate, the feed falling from the feeding pipe 3 is thrown out from around the impeller 15 under the impact of the blades of the impeller 15, and enters the feeding gap 11 from the feeding port 12, and then enters the feeding gap 11 from the feeding port 13. It is unloade...

Embodiment 3

[0040] Such as Figure 7 As shown, the automatic feeding device for free-range chickens described in this embodiment is different from Embodiment 1 in that: the lower cone surface 10 is provided with a material leakage port 17 .

[0041] In the automatic feeding device for free-range chickens described in this embodiment, during the process of unloading the feed, part of it will leak from the leakage port 17, and another part of the feed will rush through the leakage port 17 and be discharged from the discharge port 13, so that Two feed discharge points can be formed to further increase the feeding surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com