AC motor control device

An AC motor and control device technology, applied in AC motor control, motor control, motor generator control and other directions, can solve problems such as insufficient performance, and achieve the effect of suppressing electrical oscillation and stabilizing drive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

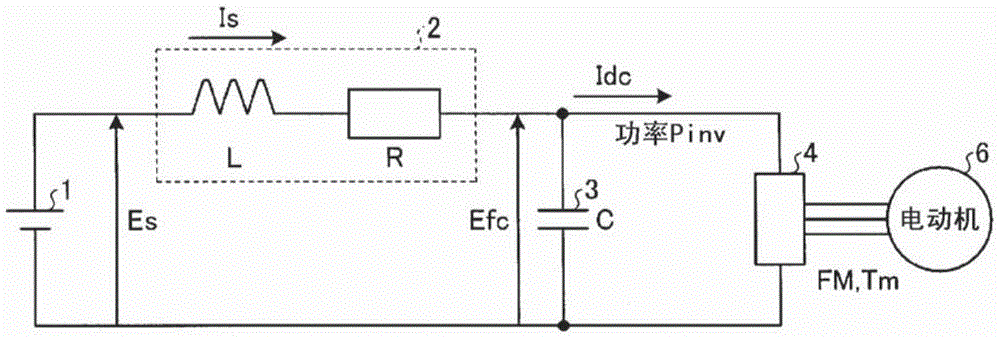

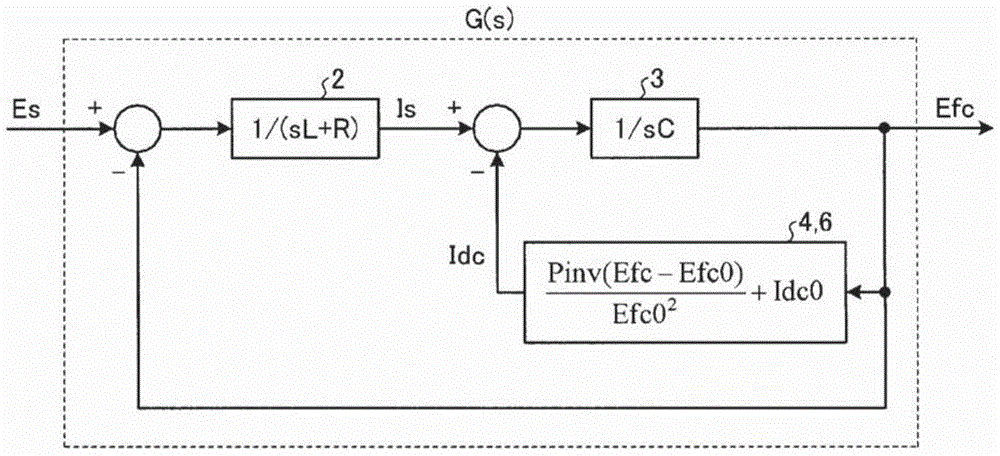

[0023] figure 1 It is a block diagram showing a configuration example of the AC motor system of the embodiment. like figure 1 As shown, the AC motor system of this embodiment has: a DC power supply 1; an LC filter circuit composed of a reactor 2 and a capacitor 3 for suppressing the high-order harmonic current from flowing out to the power supply side; (capacitor voltage) Efc is converted into an inverter 4 of an arbitrary frequency AC voltage; an AC motor 6; and an AC motor control device 50 for driving and controlling the AC motor.

[0024] The AC motor control device 50 is composed of a vector control unit 30 and an attenuation control unit 40, and is input with a signal ωr from a speed detector 7 that detects the rotational speed of the AC motor 6, and signals from the current detectors 5a to 5c that detect the motor current. Iu, Iv, Iw, and the voltage Efc of the capacitor 3 . In addition, in the present embodiment, the current detectors are provided for each of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com