Vacuum packaging, edge cutting and secondary packaging machine

A vacuum packaging and secondary packaging technology, applied in battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult equipment manufacturing and maintenance, low production efficiency, and large occupied space. Achieve the effect of improving the efficiency of machine manufacturing, simplifying the difficulty of equipment maintenance, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

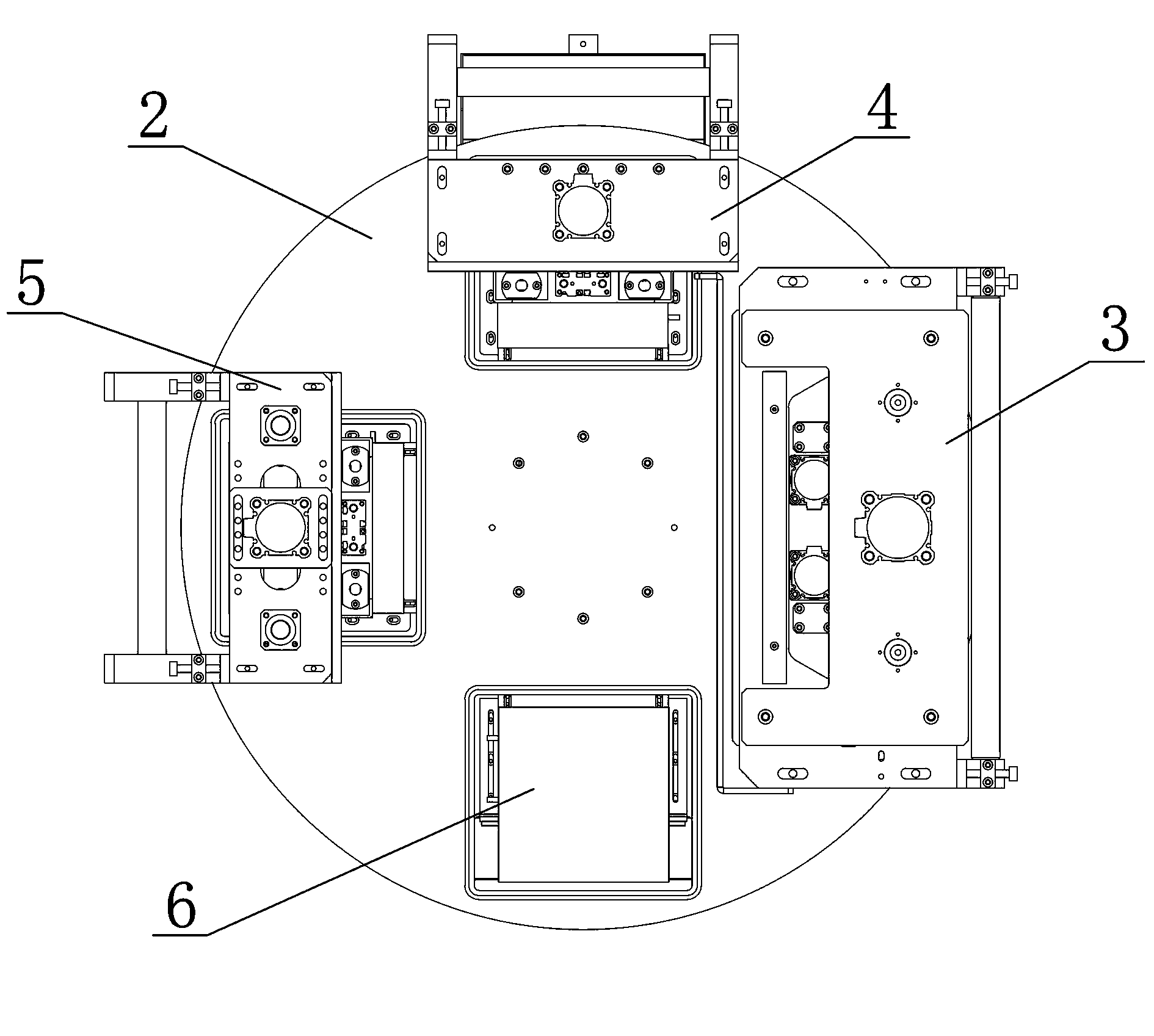

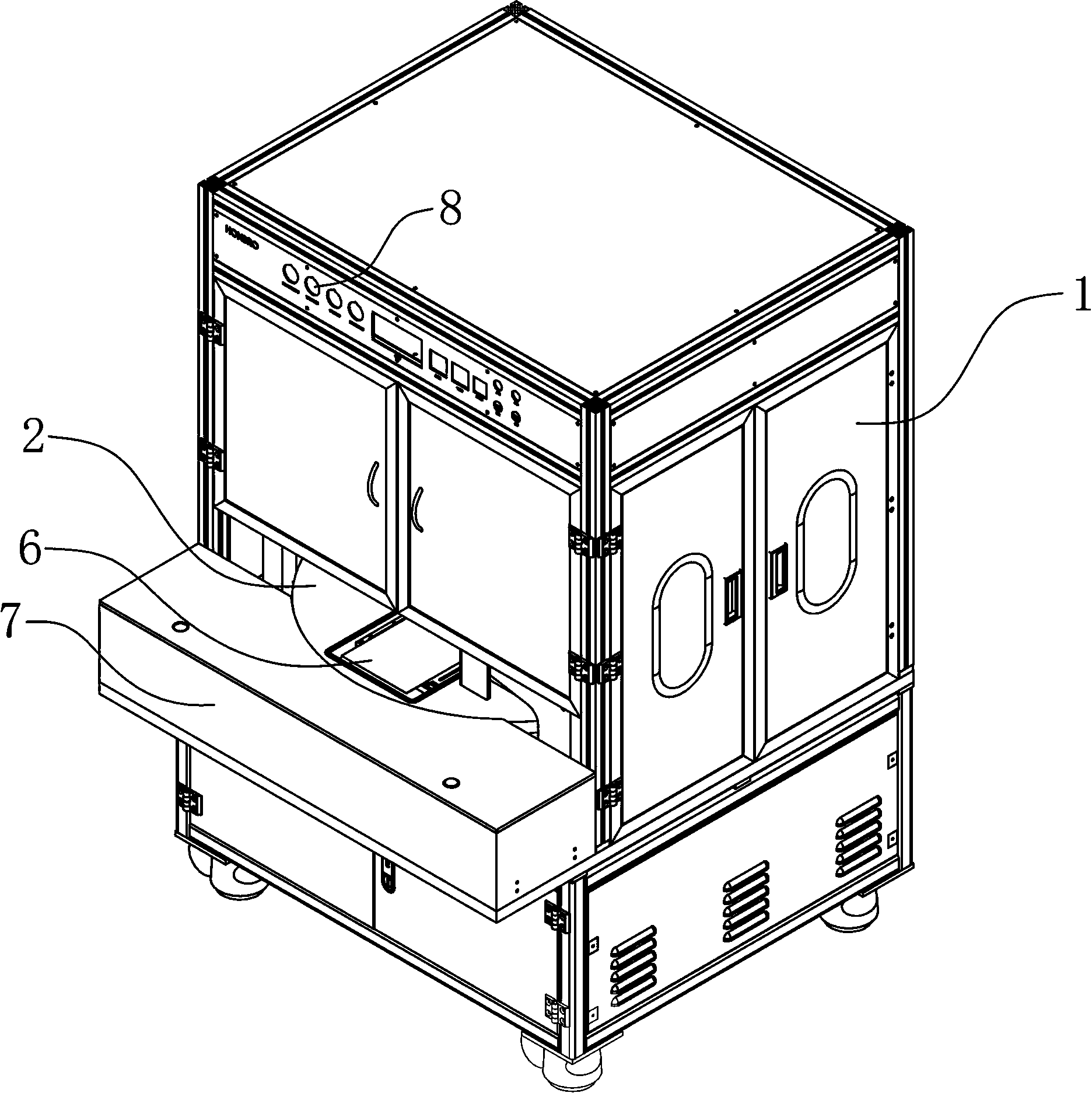

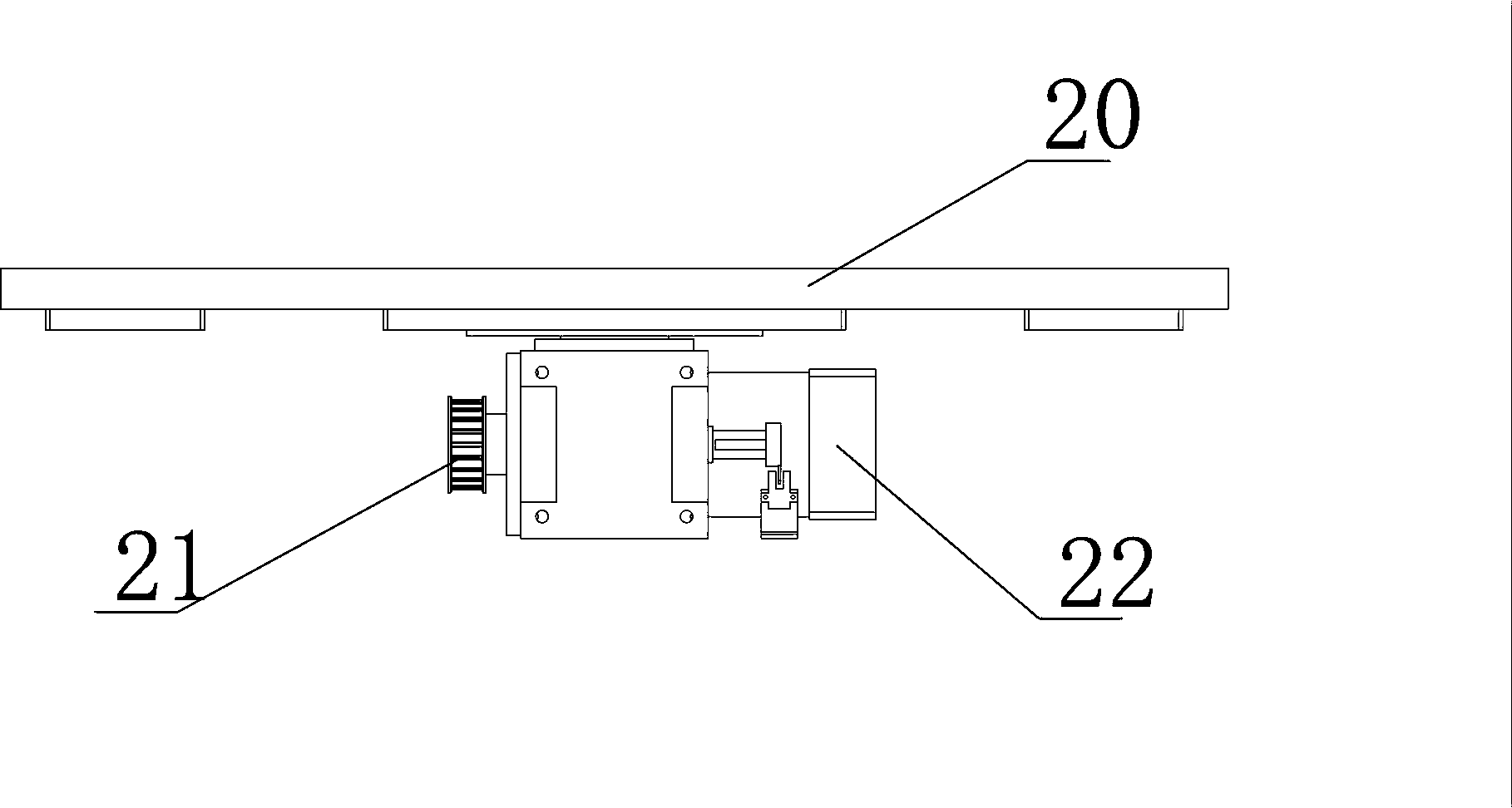

[0026] Such as Figure 1 to Figure 13 As shown, a vacuum packaging, trimming and secondary packaging machine is characterized in that: it includes a chassis 1, a turntable mechanism 2, a vacuum packaging mechanism 3, a trimming mechanism 4 and a secondary packaging mechanism 5, wherein: the chassis The inside of 1 is a cavity, and a turntable mechanism 2 is arranged in the inner cavity of the chassis 1, and a vacuum packaging mechanism 3, an edge trimming mechanism 4 and a secondary packaging mechanism 5 are respectively arranged along the circumferential direction of the turntable mechanism 2; the turntable mechanism includes a circle Shaped rotating disk 20, divider 21 and motor 22, a feeding station 6 and at least two processing stations are evenly spaced along the circumferential direction on the rotating disk 20, the workpiece to be processed is placed on the feeding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com