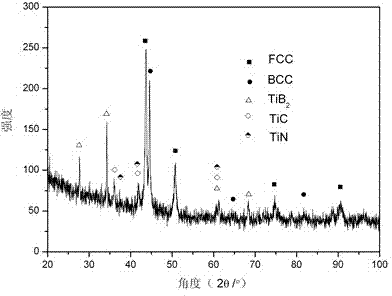

Plasma cladding in-situ synthesized TiB2-TiC-TiN reinforced high-entropy alloy coating material and preparation method thereof

A tib2-tic-tin, plasma cladding technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of low hardness and uneven structure distribution of high-entropy alloy coating, and achieve the realization of high-entropy alloy coating. The matching of hardness and toughness, easy implementation, and the effect of overcoming pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

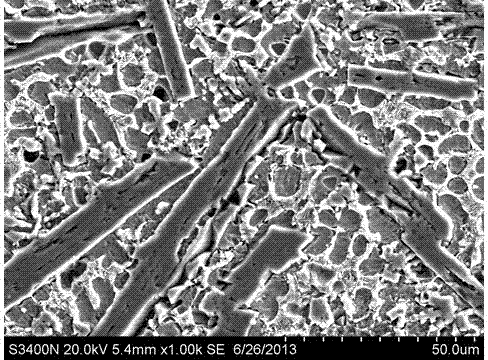

[0019] Example 1: A Plasma Cladding In-Situ Autogenerated TiB 2 -TiC-TiN reinforced high entropy alloy coating material and its preparation method:

[0020] (1) The composition of the high-entropy alloy coating material is: Co 17%, Cr17%, Fe 17%, Ni 17%, Mn 17%, Ti 10%, B 4 C 2 % and BN 3 %.

[0021] (2), the steps of the high-entropy alloy coating preparation method are as follows:

[0022] (a) Substrate pre-treatment: first cut the low-carbon steel plate into a plate of 40×60×8mm, and then use a grinding wheel to polish the surface of the steel plate to remove the oxide layer until it reveals a metallic luster; then the polished steel plate is Degreasing cleaning, using acetone solution to clean in ultrasonic waves, the temperature during cleaning is 25 ° C; after cleaning, wipe the surface of the steel plate with alcohol and dry it in a drying box for subsequent use;

[0023] (b) Prepare the high-entropy alloy coating raw material: accurately weigh the coating raw mate...

Embodiment 2

[0027] Example 2 : A kind of plasma cladding in situ self-generated TiB 2 -TiC-TiN reinforced high entropy alloy coating material and its preparation method:

[0028] (1) The composition of the high-entropy alloy coating material is: Co 18%, Cr18%, Fe 18%, Ni 18%, Mn 18%, Ti 7%, B 4 C 1 % and BN 2 %.

[0029] (2), the steps of the high-entropy alloy coating preparation method are as follows:

[0030] (a) Substrate pretreatment: first cut the low-carbon steel plate into a plate of 50×70×8mm, and then use a grinding wheel to polish the surface of the steel plate to remove the oxide layer until it reveals a metallic luster; then the polished steel plate is Degreasing cleaning, using acetone solution to clean in ultrasonic waves, the temperature during cleaning is 25 ° C; after cleaning, wipe the surface of the steel plate with alcohol and dry it in a drying box for subsequent use;

[0031] (b) Prepare high-entropy alloy coating raw materials: accurately weigh the coating raw m...

Embodiment 3

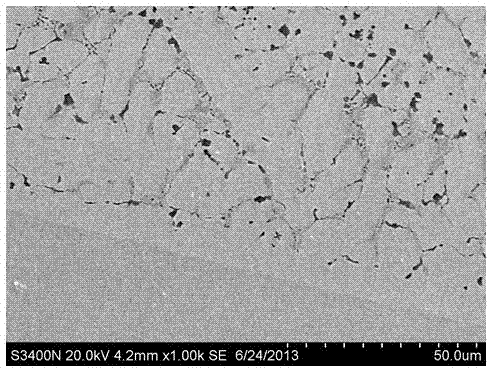

[0035] Example 3: A Plasma Cladding In-Situ Autogenerated TiB 2 -TiC-TiN reinforced high entropy alloy coating material and its preparation method:

[0036] (1) The composition of the high-entropy alloy coating material is: Co 19%, Cr19%, Fe 19%, Ni 19%, Mn 19%, Ti 3%, B 4 C 0.5% and BN 1.5%.

[0037] (2), the steps of the high-entropy alloy coating preparation method are as follows:

[0038] (a) Substrate pretreatment: first cut the low-carbon steel plate into a plate of 60×80×8mm, and then use a grinding wheel to polish the surface of the steel plate to remove the oxide layer until it reveals a metallic luster; then the polished steel plate is Degreasing cleaning, using acetone solution to clean in ultrasonic waves, the temperature during cleaning is 25 ° C; after cleaning, wipe the surface of the steel plate with alcohol and dry it in a drying box for subsequent use;

[0039] (b) Prepare high-entropy alloy coating raw materials: accurately weigh the coating raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com