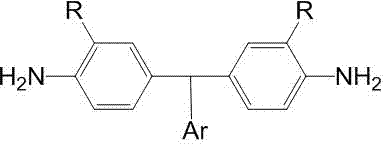

Diamine monomer containing asymmetric and non-coplanar structure, and preparation method of diamine monomer

A non-coplanar, diamine monomer technology, applied in the field of aromatic diamine monomer and its preparation, can solve the problems of reducing the thermal stability of polyimide, and achieve the effect of low cost, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

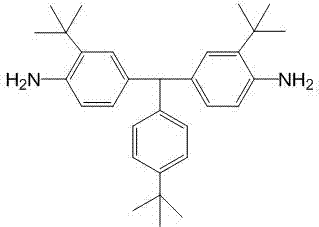

Embodiment 1

[0035] (1) 6.5 grams (0.040 moles) of 4-tert-butylbenzaldehyde and 1.5 milliliters of 12 N hydrochloric acid were uniformly mixed to prepare a mixed solution.

[0036] (2) Under the protection of nitrogen, raise the temperature of 15 g (0.100 moles) of 2-tert-butylaniline to 120 ° C, and then add all the mixed solution prepared in step (1) dropwise within 1 hour, and keep stirring after the dropwise addition After 30 minutes, heat up to 160°C and reflux for 10 hours, then cool to 60°C, gradually add 10% sodium hydroxide aqueous solution drop by mass to neutralize, continue cooling to room temperature, and then add dichloromethane Extracted, washed 3 times with distilled water, then dried overnight with anhydrous sodium sulfate, filtered, and the solvent was removed by rotary evaporation, and the obtained crude product was further purified by silica gel column chromatography (the eluent was a volume ratio of 1:8 Ethyl acetate and petroleum ether mixture), and finally a light ye...

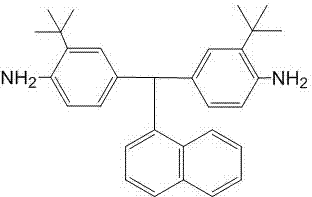

Embodiment 2

[0039] (1) 6.0 g (0.038 mol) of 1-naphthaldehyde and 1.5 ml of 12 N hydrochloric acid were uniformly mixed to prepare a mixed solution.

[0040] (2) Under the protection of nitrogen, raise the temperature of 15 grams (0.100 moles) of 2-tert-butylaniline to 110 ° C, then add the whole mixed solution prepared in step (1) dropwise within 1.5 hours, and keep stirring after the dropwise addition After 30 minutes, heat up to 150°C and reflux for 12 hours, then cool to 60°C, gradually add 10% sodium hydroxide aqueous solution drop by mass to neutralize, continue cooling to room temperature, and then add dichloromethane Extracted, washed 4 times with distilled water, then dried overnight with anhydrous sodium sulfate, filtered, and the solvent was removed by rotary evaporation, and the crude product obtained was further purified by silica gel column chromatography (the eluent was a volume ratio of 1:6 Ethyl acetate and petroleum ether mixture), the final white powdery solid is a diami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com