Low-gram-weight and high-performance PE (Poly Ethylene) embossing film and manufacturing technology thereof

A production process, high-performance technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of unstable product thickness, decreased physical properties of products, increased manufacturing costs, etc., to eliminate mutual Interlocking problem, ensuring product thickness, reducing the effect of friction coefficient

Active Publication Date: 2014-01-01

FOSHAN HUAHAN SANITARY MATERIAL

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] At present, domestic manufacturers have produced low-weight PE embossed films. However, the low-weight PE embossed films produced by domestic manufacturers generally suffer from weight loss and physical properties of the products. Unfavorable phenomena such as "bones and tendons" are prone to occur after winding

High-performance low-weight PE embossed film still mainly relies on imports, so to a certain extent, it increases the manufacturing cost of high-quality disposable sanitary products, disposable medical protective products and industrial protective products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0027] To produce low-weight high-performance PE embossed film, the first layer is 90% mLLDPE and 10% color masterbatch; the second layer is 85% HDPE and 15% color masterbatch; the third layer is 88% LDPE, 10% color masterbatch and 2% slip agent; the above raw materials are tested for cleanliness, purity and moisture content, and stirred and mixed according to the ratio set by the product.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

| Pull | aaaaa | aaaaa |

| Maximum pull | aaaaa | aaaaa |

Login to View More

Abstract

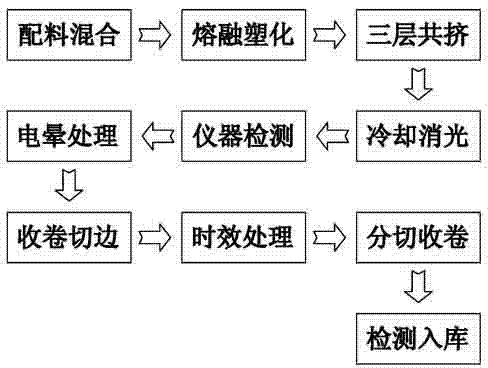

A low-gram-weight and high-performance PE embossing film is characterized in that the embossing film comprises three layers of films formed through co-extrusion; the surface of the embossing film is subjected to corona treatment; the components and the weight percentage of the three film layers are as follows: a first layer comprises the components in percentage by weight as follows: 85%-95% of m LLDPE (linear low density polyethylene) and 5%-15% of color masterbatch; a second layer comprises the components in percentage by weight as follows: 85%-95% of HDPE (high-density polyethylene) and 5%-15% of color masterbatch; and a third layer comprises the components in percentage by weight as follows: 83%-93% of LDPE (low-density polyethylene), 5%-15% of color masterbatch and 1%-2% of a slipping agent. According to the low-gram-weight and high-performance PE embossing film, the material of the slipping agent in a certain proportion is added to the formula and subjected to co-mixing with the LDPE, the friction coefficient of the film surface is reduced, the adhesion problem among films is eliminated, and the texture is more smooth; good co-mixing and plasticizing effects of the materials are guaranteed by the aid of a three-layer co-extrusion casting technology, and the problems that the co-mixing effect of a conventional single-layer co-extrusion technology is poor, and the plasticizing is not good are solved; and the die head gap is controlled through the system and the flow of a molten plastic fluid is controlled through a metering pump, so that the film casting stable linear extrusion is realized.

Description

technical field [0001] The invention relates to a PE embossed film and a production process thereof, in particular to a low-weight high-performance PE embossed film and a production process thereof. Background technique [0002] PE embossed film can prevent the penetration of liquid, has the function of anti-permeation and anti-pollution, soft and comfortable, and has a high-grade paper effect in appearance, so it is widely used in women's sanitary napkins, sanitary pads, baby diapers, adult incontinence Production of leak-proof layers for supplies, disposable medical and industrial protective supplies such as surgical gowns and shoe covers. [0003] According to statistics, in 2011, the output of adult paper diapers in my country was about 937 million pieces, the export volume was about 237 million pieces, and the consumption volume was about 631 million pieces; the total market size of sanitary napkins and sanitary pads was about 26.28 billion yuan, an increase of 7.9% ove...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B27/06B32B27/32B29C47/06B29C47/92B29C48/92

CPCB29C48/92B29C2948/92704B29C2948/92152B29C2948/92428B29C2948/92647B29C2948/92895B29C2948/92904

Inventor 蔡耀钧李伟佳周飞陈恒春何大海冯小芬李伟锋

Owner FOSHAN HUAHAN SANITARY MATERIAL

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com