Aluminum alloy cable core and method for preparing same

A cable and aluminum alloy technology, which is applied in the field of aluminum alloy cable core and its preparation, can solve the problems of electrochemical corrosion of joints, uneven bolt materials, and small bolt pressing force, and achieves good fatigue strength, Excellent mechanical properties and stable resistance

Inactive Publication Date: 2013-12-25

SICHUAN AOSHENDA GENERAL CABLE

View PDF5 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that the creep resistance is poor. The thermal expansion and contraction caused by power-on and power-off will cause creep at the joint, and it will relax after a long time. Cause accidents; the materials of the bolts connecting the terminals to the equipment or the busbar are uneven, even iron bolts, the expansion coefficients of the metal materials are different, and spring washers are not installed during installation, causing air to enter and form an oxide film, which makes the contact resistance Increasing and overheating is also a hidden danger

The terminals used for pure aluminum cables are not specially treated, and the connection with copper bars may cause electrochemical corrosion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

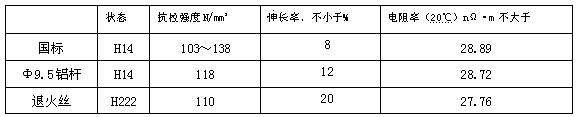

The invention discloses an aluminum alloy cable core and a method for preparing the aluminum alloy cable core. The cable core is composed of 0.06wt% of Si, 0.40-1.2wt% of Fe, 0.05wt% of Cu, 0.01-0.05wt% of Mg, 0.01-0.3wt% of RE, 0.05wt% of Zn, 0.04wt% of B and the rest of Al. According to the aluminum alloy cable core and the method for preparing the aluminum alloy cable core, rare earth resources in China are utilized; after rare earth elements are added to conductor materials, aluminum alloy conductors which are extremely competitive in conductivity, flexibility, bending property, tensile property, creep resistance and connecting stability and excellent in resistance to corrosion are prepared through the smelting process, the rod drawing process, the wire drawing process, the compressing process and the stranding process and special annealing treatment; after being detected and verified by authorities at home and abroad, the compensative performance of the aluminum alloy cable core is far beyond current industry standards at home and abroad; high-tech aluminum alloy cable products can be widely applied to fields like electric power, automobiles, traffics, mineral products, ships, chemical industries and military, and the advantages of the high-tech aluminum alloy cable products are more obvious when the high-tech aluminum alloy cable products are used in complex and severe engineering environments.

Description

technical field [0001] The invention relates to a cable core, in particular to an aluminum alloy cable core and a preparation method thereof. Background technique [0002] Copper is listed as a strategic reserve material second only to petroleum in my country, and my country is a country lacking in copper ore resources and a big copper-consuming country. According to statistics from the China Nonferrous Metals Industry Association, as of 2009, China's reserves of copper resources were about 30 million tons, accounting for about 5% of the world's total reserves. At present, the annual domestic copper consumption is about 7 million tons, of which the copper consumption for wires and cables accounts for about 65% of the national copper consumption, accounting for a large proportion. If it is not imported, my country's copper resources can only be used for 5 years. In this way, my country needs to spend a large amount of foreign exchange to import copper every year, accounting ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/00C22C21/02H01B1/02H01B13/00H01B7/04

Inventor 李建国唐斯弟程继刚刘莉萍

Owner SICHUAN AOSHENDA GENERAL CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com